CAM Automation is a Process, not a Goal

Automated NC programming requires a strategy to yield improved productivity, quality and consistency.

With a shrinking pool of journeymen mold builders to rely on, it is of strategic interest to mold manufacturers to find a better way to utilize their existing talent. Better leveraging the skills of current employees can allow companies to more easily scale operations to meet customer demands in manufacturing. Unfortunately, even after tapping into these resources, NC programming efforts remain a bottleneck within most organizations.

Time-consuming, manual NC programming techniques remain the standard approach for today’s mold builders. Although this approach can be successful, it requires highly trained employees and can still result in a high variance in programming time, milling time and surface finish for individual projects. This is true even when many of the NC programming steps are done by rote.

Standard components and processes for plates, lifters, inserts, and cavities and cores can represent between 75 and 90 percent of any moldmaking shop’s NC programming efforts. This offers incredible potential for mold builders to realize a return on investment in automated NC programming. Benefits of automated programming include:

• Minimal time and associated costs for training new employees.

• Increased consistency and throughput, as all employees benefit from established best practices.

• Reduced errors, which are inherent in manual processes.

• Less time required for NC program generation.

• Improved use of employee time, enabling them to focus on more value-added activities.

With these benefits, why hasn’t NC programming automation become a standard practice?

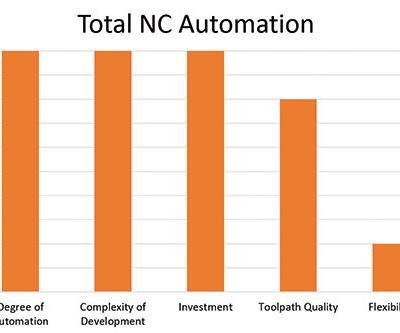

Historically, the industry’s approach to automation has been to identify a family of geometries that can generate 100-percent-safe, efficient NC programs without any user interaction. This is total NC automation, and the process involved can be paralyzing in its complexity, require strict adherence to process standards in both design and manufacturing, and demand a significant financial investment in custom code created for the API (applications programming interface) of the host CAM system.

The resulting automation solution is often abandoned by staff due to its inflexible nature. While total NC automation certainly represents the theoretical ideal, this style of automation does not necessarily guarantee a return on investment. Its “all-or-nothing” approach puts too much of the focus on failure. Rather than being focused on the vast majority of projects related to the common features and processes that can benefit from automation, attention and investment instead fall on the minority of designs and projects that cannot be well-captured by a standard process.

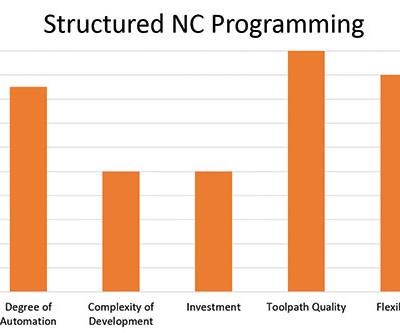

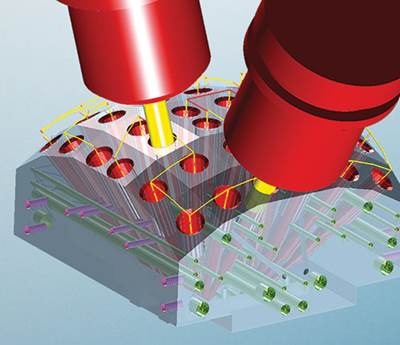

A more modern approach is structured NC programming in which a series of utilities or applications is created to streamline the programming and automate many functions based on the knowledge of the most qualified personnel. This programming environment offers maximum flexibility for manufacturing and is interactive by its very nature. It allows for intelligent application of automation where the CAM user finds it appropriate, but also lends structure for streamlining processes by relying on the best practices stored in the CAM application.

For mold builders, cavities and cores may be the most difficult work for which to visualize a standard process because, by their very nature, these applications cannot be automated in full. The necessary finishing processes are determined by the individual products and the smallest radii. However, it can be a realistic goal to automate most of the process through structured NC programming, which can deliver a product with a consistent semi-finish to skilled personnel for final finishing operations.

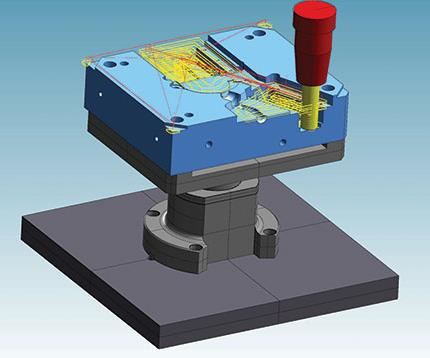

The structured NC programming environment for cavity and core work might appear as follows:

1. Import model, define stock, assign fixture and create all required work planes.

2. Perform block-sizing operations (for example, face milling and contouring).

3. Implement feature recognition for hole geometry and macros used to assign machining strategies for holes.

4. Create rough and re-rough strategies by selecting the cutting tool series based on machine, material and project.

5. Implement feature recognition for pocket geometry and macros to assign finishing strategies to pockets.

6. Select corner-picking routines by choosing a series of cutters based on the smallest radius.

7. Create semi-finish tool paths.

A structured NC programming environment can yield a faster return on investment, as the smaller process steps are simpler to define, manage and understand, and it may be easier to provide justification for each step individually. If the cost or benefit of a particular step is not clear, this step can remain with the traditional, manual process.

Companies that successfully pursue a strategy of automation will understand that it is not a goal to be achieved but rather a process to be continually pursued, refined and leveraged over time. Structured NC programming creates the environment where this strategy is best fostered.

OPEN MIND Technologies USA Inc.

Related Content

5 Ways to Make Your Tooling Assets Smarter

Global mold monitoring and asset management solutions can maximize productivity and efficiency.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreEnhancing Global Manufacturing Visibility: How Digital Moulds Solved SKF's Data Accessibility Challenges

SKF improved global manufacturing visibility and data accessibility through Digital Moulds' cloud-based monitoring system, enhancing real-time machine status tracking.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreRead Next

CAM Reduces Cycle Time when Machining Mold Bases

Feature recognition, CAM capabilities and machine controller interaction can reduce cycle time when machining mold bases.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More