New Michigan Technical Center for YCM Alliance

YCM Alliance held a grand opening of its new Technical Center in Sterling Heights, Michigan, last week, which is the first in a series of centers designed to showcase and demo machining solutions for die and mold machining, ultra-high-speed machining and general parts machining.

Visitors to YCM Alliance Michigan Technical Center Grand Opening challenged application experts with their unique requirements, compared different technologies, ran test cuts, conducted time analysis and witnessed firsthand the level of precision and quality that is achievable.

YCM Technology Centers are designed as a production environment but also feature meeting rooms to discuss processes, business considerations and YCM’s own finance options. There is even a cafeteria so visitors and customers can be as productive as possible during a visit.

“YCM Alliance’s Grand Opening was a great experience with an excellent setup and display. The experience of their sales force is second to none. We are excited to continue working with YCM as we grow our business,” Steve Michon, President, Zero Tolerance.

Interactive machining demonstrations included high-performance vertical machining, multi-axis machining, double-column machining, portal machining, ultra-high-speed machining (steel/graphite), horizontal machining, gantry sinker EDM, wire-cut EDM, die/mold spotting, high-efficiency turning and machining automation.

In addition to demos were presentations from industry experts on a variety of important topics, including a North American manufacturing industry report, AM molds, using technology to solve the skills gap, machine controls, five-axis milling/EDM/automation, CAM for five-axis machining, moldmaking automation and hybrid milling and deep-hole drilling.

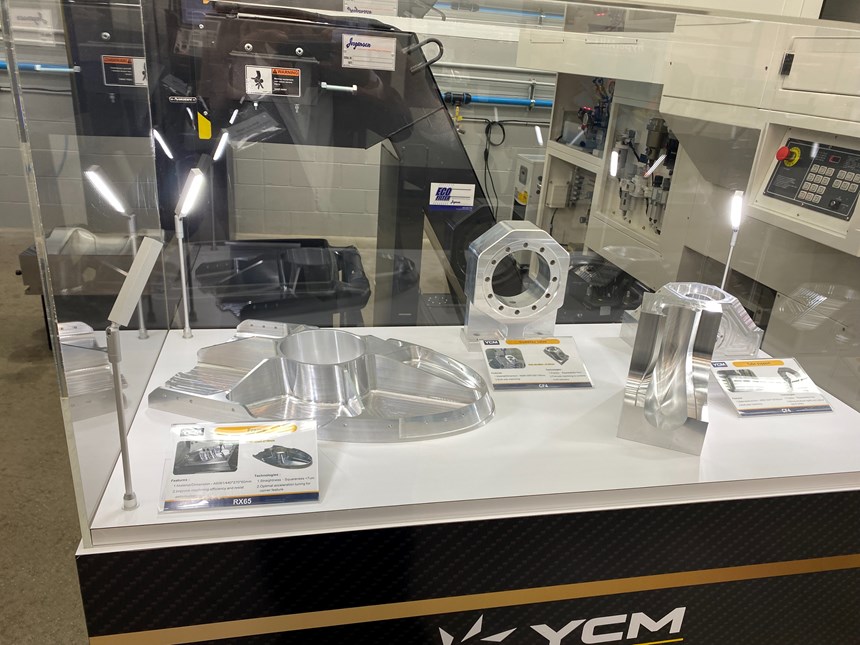

Machine technology on display at YCM ALLIANCE Michigan technical center grand opening

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

.jpg;maxWidth=970;quality=90)