Omega Tool, Eden Tool, CDM Tool, United Tool and Mold, Precise Tooling Solutions, Superior Tooling, Die Tech, Westminster Tool, Triangle Tool, Janler, Innovation Mold, Delta Mold, Century Tool, Michiana Global Mold, Intralox, R&D Leverage, Met-L-Flo, Custom Mold, Nypromold, Tessy Tooling, Evco Plastics, iMFLUX, Hanson Mold, Concept Molds, Accutech Mold, Integrity Mold, Decatur Mold and Redoe Mold. These are a handful of mold builders not just walking IMTS, but seriously investigating product and equipment purchases.

This activity aligns with a recent informal reader survey that revealed many of MMT’s readers are building more molds than last year and running more machine hours. They also noted they want to buy more mold steels, aluminum, cutting tools and machines. Mold builders are after technology to help them improve surface finish, efficiency, accuracy, setup and cycle times, and IMTS served it up!

Moving moldmaking forward takes the right technology, processes and partnerships to develop solutions that improve mold-building efficiency, and IMTS is a great place for that to happen.

Precision Products & Professionals

Editorial director Christina Fuges and managing editor Grace Nehls worked the IMTS show floor for MoldMaking Technology readers. Photo Credit, all images: MMT

This is a challenging show to manage with MMT’s small (but mighty) editorial staff. Still, we did our best to home in on the exhibitors that offer technology solutions for our niche audience (You can read about the show from managing editor Grace Nehls point of view here). However, the following is still just a small sampling of the products and equipment IMTS brought to the table this year. Here are 10 machining, cutting tools, software and inspection products displayed across the North, South, East and West halls of McCormick Place that caught my eye:

- I got a lesson in VMCs, HMCs and five-axis machining over at the DN Solutions booth, where they debuted the BVM 5700 VMC, a machine that handles heavy workpieces and cuts with increased rigidity. Plus, it comes to end users with standard features right out of the box.

- At the Hurco booth, I was shown the Takumi VC1052, a fast, three-axis linear guide machine, which is a popular design for mold builders with direct-coupled motors and double-anchored ballscrews to eliminate lost motion.

- Hwacheon Machinery America showed off its heavy-duty, precise five-

axis machine D2-5AX, which offers enhanced rigidity, automation options and a scheduling system to increase productivity.

Many mold builders came to IMTS to check out five-axis machine tools.

- CGS North America was selling CAM-Tool, but what really caught my eye was the Quick Quote software it promoted at the corner of its booth. It is pre-installed with average material costs and work per hour, reflecting the mold industry’s general reality. This enables mold builders to start the quotation immediately, without complex customizations.

- When I asked to see some proven mold-building technology, Iscar staff pointed out its Spinjet coolant-driven spindle with real-time rpm monitoring, which is part of its NeoLogIQ line.

- If you needed a VR fix, IMTS had it. My visit to the Kubotek booth with

colleague Rachel Wallis to check out its CAD interoperability products included a demo of their prototype VR experience.

Virtual reality was a tool used to attract attendees and demonstrate its usefulness.

- Faro got right to the point with its FARO Quantum Max ScanArm that gets the inspection job done as quickly and precisely as possible. Its xR, xP and xS offerings help mold builders with speed, accuracy and resolution.

- A stop at Open Mind Technologies let me see the actual blow mold we featured in a story earlier this year on its customized CAM strategies for improving five-axis blow mold machining.

- Moldmaking is all about precision and many machine tool builders highlighted those capabilities, but the James Webb Space Telescope in the Mitsui Seiki booth couldn’t help but stand out.

- I also can't forget when I stepped into the Trimill VFC 3021 in the YCM

booth, which I was told was already sold. This rigid five-axis machine was developed for injection molds, offering high dynamics and accuracy.

Molds come in all shapes and sizes and the right machine tool is key.

Many more booth visits revealed a variety of other impressive technology solutions for mold builders that we can’t review here. Still, we will cover them with more in-depth technical content in the coming months. So stay tuned to MMT!

Podcasts & Parties

It wouldn’t be an IMTS without a few industry interviews and opportunities to unwind with industry colleagues. This year I had the pleasure of interviewing one of our readers, Eden Tool and Eden Manufacturing President Dave Tomic. MoldMaking Technology had an exhibit within the Gardner Business Media booth where he was on hand to explain his shop’s “predictable manufacturing” philosophy via a complex medical mold on display.

Eden Tool has perfected predictable moldmaking and hard milling is the foundation. Check out this retractable need mold for the medical industry.

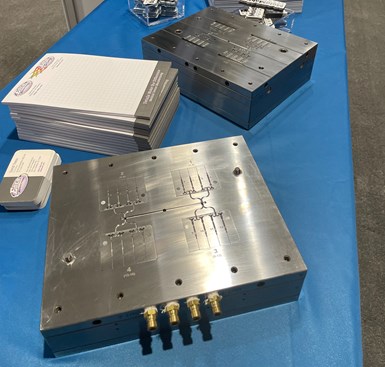

This SPI Class 101+ retractable needle mold features critical plastic part features, mini-tunnel gates and long-lasting components, showcasing the precision mold machining capabilities of the Eden Tool team, which is impossible without the commitment of technology suppliers like those exhibiting at IMTS!

I was also honored to be a guest on IMTS Shop Talk with AMT’s Bill Herman to explain why moldmaking is a critical sector of manufacturing that deserves its own publication and media channel, share who makes up this community of mold manufacturers, how the industry has evolved since the last IMTS, what the hot moldmaking topics of the day are, which IMTS exhibitors are offering technology solutions for mold and die and what mold builder is being featured in the MMT booth and why.

AMT’s Bill Herman and MMT’s Christina Fuges discuss all things moldmaking on the “big stage” in the Grand Concourse of McCormick Place during IMTS Shop Talk.

I also sat down with James Soto of Industrial Strength Marketing in the Industrial Studio to catch up on how MoldMaking Technology has evolved its manufacturing storytelling through digital content, such as our weekly MMT Chat video interviews.

Mold builders came together to hang out and make new connections.

Three bonus networking events were an impromptu happy hour with a few MoldMaking Technology readers where I actually saw live connections being made (one of the most rewarding parts of my job!), a wonderful press dinner by Gorman Pompili Communications in the Rice Gallery of the Chicago Field Museum and Gardner Business Media’s Ladies Night, which has grown in popularity and attendance as the number of women in manufacturing steadily increases!

It bears repeating that this review is only a glimpse of what I saw, heard and experienced during this exhausting but exhilarating week at IMTS. So stay tuned. Events like IMTS are what fuel the ideas that end up on the pages of MMT to help educate and inspire this critical niche of manufacturing.

Related Content

How to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreDesign Strategy Tackles Big and Small Complexity Challenges for Southeastern Mold Builder

Delta Mold Inc.’s core values, engineering expertise, five-axis machines and molding capabilities help the team turn a proposal into a manufactured mold or part with custom design, finishing and assembly.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)