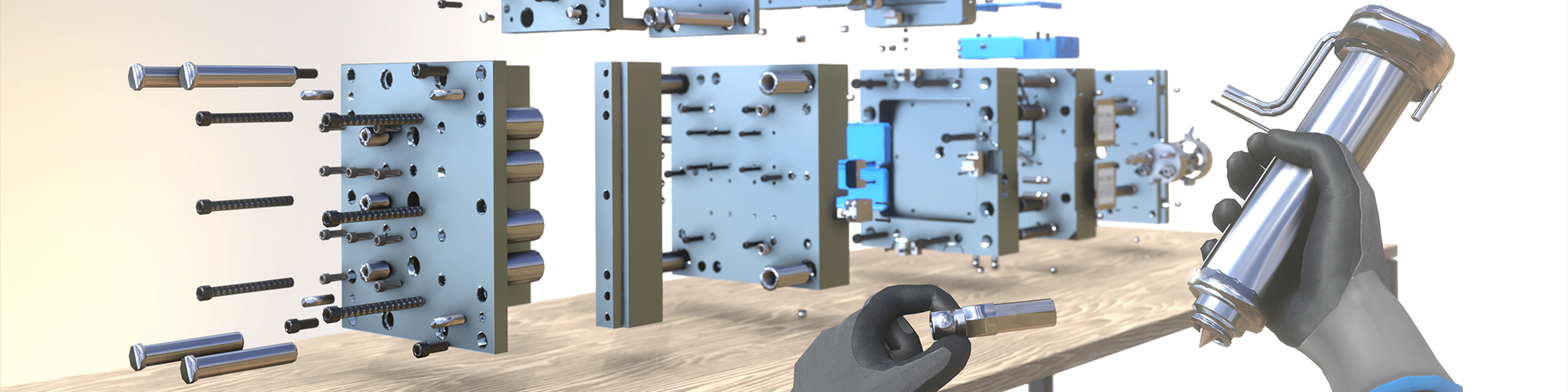

Photo Credit, clockwise from top left: Shop Floor Automations, Longterm Technology, ATC Diversified Manufacturing and ECI Software.

Software solutions are used across many sectors in manufacturing — and moldmaking is no exception. With all of the different products and services out there, the task of finding the right software that works for an individual mold shop can be intimidating, but this month’s Moldmaking Technology tech roundup can help, whether it’s for streamlining processes, boosting efficiency, providing data important to production or more.

To check out tech roundups from months prior, please browse the “New Tech” section of the MoldMaking Technology website, or look up “Technology Roundup” in the homepage Search bar. For more information on a product featured below, click on the title link for the respective product.

For other software-related posts, take a look at the following articles:

- “Advancing the Mold With New Technologies”

- “Products and Services for Multiple Moldmaking Needs”

- “Technology Roundup: Software”

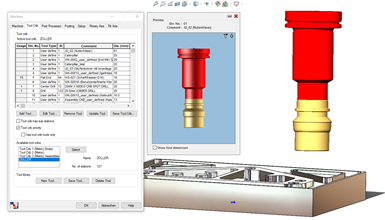

Photo Credit: HCL Technologies

Advanced CNC Programming Interface Streamlines Tool Management

HCL Technologies (HCL) announces the implementation of Zoller TMS Tool Management Solutions Interface in HCL CAMWorks software. The Zoller Interface is said to supply customers with advanced tool database management options, an overview of available tools and eliminate the need to maintain multiple tool databases.

Photo Credit: CGTech

Simulation Software Updates for Smarter Machining, Mold Manufacturing

CGTech announces the latest release of Vericut version 9.3, a software program used for simulating CNC machining, additive and hybrid manufacturing processes. The software operates independently, but also integrates with all leading CAM systems.

Vericut 9.3 focuses on creating “smarter,” more efficient manufacturing processes with features that bring in data around the machine, the tools and the stock to improve simulation and the overall manufacturing workflow, according to the company.

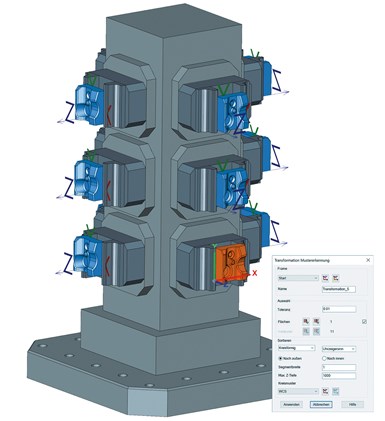

Photo Credit: Open Mind Technologies USA

CAD/CAM Software Suite Optimized for High Moldmaking Productivity

Open Mind Technologies introduces its latest hyperMill 2023 CAD/CAM software suite, which offers users new and enhanced features for powerful and simplified NC programming in applications ranging from 2.5D machining to five-axis milling.

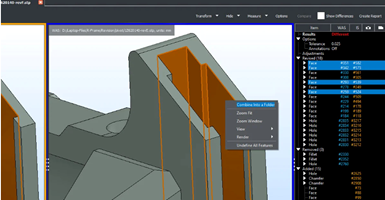

Photo Credit: Kubotek Kosmos

Enhanced Utility Programs Streamline CAD Data Transfer

Kubotek Kosmos has released version 5.0 of its CAD/CAM software interoperability products: Validate, Revision, Convert and View. These CAD utility programs use proprietary Kubotek Kosmos modeling technology to support transfer of precise CAD data across the manufacturing supply chain. This release drops the K-Compare and K-Display brand names and provides updates to CAD file readers and user interface improvements.

Photo Credit: CoreTech Systems

Latest Mold Analysis Software Meets Injection Molding Needs

CoreTech Systems responds to the transformational needs of plastic injection molding through Moldex3D 2023, its latest version of the molding analysis software. The new generation focuses on four main concepts: reliability, efficiency, augmentation and liberation.

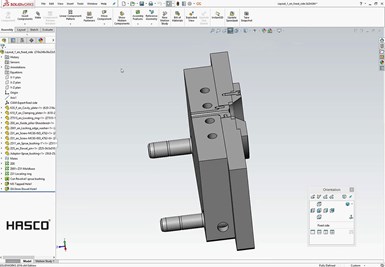

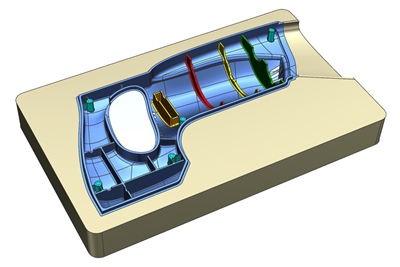

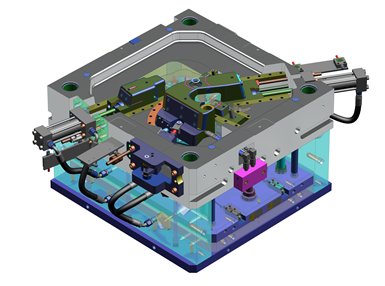

Photo Credit: Longterm Technology Services

Updated Module Simulates Mold Designs for Full Cycle Collision Check

The latest version of Dynmik Design for Mold (DDM) from Longterm Technology Services (Longterm Tech) is now available. An industry-crafted module for Siemens NX Mold Wizard, DDM simulates mold designs in 4D motion for full cycle collision checking. Mold shops using the solution have saved more than $50K a year in time and money being lost to tooling design errors or unnecessarily long validation timelines, the company says.

CAD/CAM Software Update Adds Features, Functions

CAM-Tool from CGS North America, a CAD/CAM software designed for high-accuracy machining in the mold and die sector, is updating to version 19.1. Focused on increasing productivity and accuracy, this update includes several distinctive features and functions.

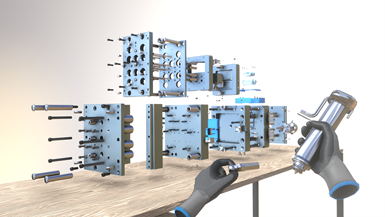

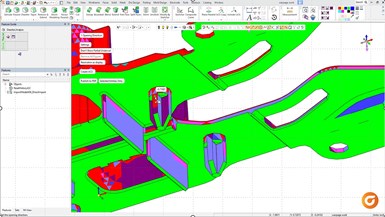

Photo Credit: Cimatron

Software Simulation Eases Design Challenges for Moldmakers

Cimatron provides toolmakers with an integrated CAD/CAM solution for the design and manufacture of plastic injection molds and sheet metal stamping dies, as well as programming 2D to five-axis milling CNC machines. Cimatron is a single-source solution with a single, intuitive, easy-to-use interface for a shop’s entire workflow — from quoting, to design, to manufacturing.

Related Content

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreRead Next

Five Key Aspects of a Basic Multi-Axis AM Programming Workflow and CAD/CAM/AM Tools

CAD, CAM and AM tools in the same software package and user interface ease programming for mold builders employing additive manufacturing operations.

Read MoreSimulation is a Process, Not Just Software

To reap the benefits of simulation, you must view it as a process requiring you to change the way you work in part and mold design.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More