Innovating in an Ever-Changing Manufacturing Landscape

Innovation ensures your company remains adaptable to market changes and customer demands. These latest industry products/services are key to this objective.

Innovation and investing in new equipment are crucial for several reasons. Upgrading to the latest technology enhances efficiency by automating processes and reducing cycle times, which directly leads to higher productivity. Moreover, advanced machinery often improves precision and quality control, minimizing defects and waste, thereby lowering production costs and increasing profitability. Arguably the most important, however, is how equipment affects how quickly a shop can adapt to market changes and customer demands.

Below you’ll find recent technology announcements geared toward these innovation objectives, from Industry 4.0 implementation (updated software suites, digital twins, CMM programming) to cutting tools (end mills and inserts) to new website designs to more easily navigate purchases. Read on to find out more.

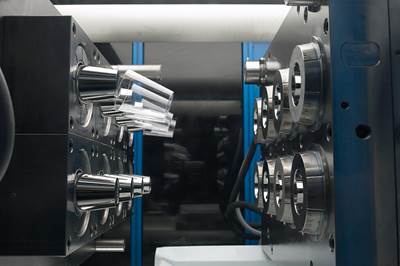

Speed Increasers Promote High Spindle Speeds for Handling Thick, Large Workpieces

Platinum Tooling Technologies is now supplying this additional equipment from Henninger to North America, useful for drilling, tapping and milling mold applications, among others. The spindle speed of the machine can be increased by a selected factor (e.g., 2:1, 3:1 and 4:1) to increase cutting efficiency based on a variety of material and heat dissipation factors, thus reducing production time for moldmakers.

M-2 Steel Pins Well Suited for Abrasive Applications

Progressive Components announces the release of its new M-2 ejector pins, which are especially suited for high wear resistance with abrasive materials.

Engineered and manufactured to meet the demanding conditions of today’s injection molds, Progressive’s ejector pins feature tight tolerances held for sizing, roundness and straightness.

Process Monitoring, Cold Runner and Nozzles Bring Control, Industry 4.0 to the Mold

Hot runner solutions manufacturer Ewikon highlights a nozzle range for vertical multi-gating as well as solutions for process monitoring and cold runner solutions for the efficient processing of liquid silicone rubber (LSR).

The HPS III-MV multi-tip nozzle for the vertical gating of parts is now available in a new, more powerful version. The nozzle features state-of-the-art hot runner technology with optimized temperature control — a coil heater integrated into the pressure tube provides stable heating and an even temperature profile.

2024 Software Suite Update Optimizes Tool Paths, Machining Capabilities

Open Mind Technologies brings customers the latest hyperMILL 2024 CAD/CAM software suite which includes a range of enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency.

Universal Metrology Platform Enables Moldmakers to Scale Up 3D Measurement Data

Independent software development company InnovMetric announces the launch of PolyWorks 2024, an enterprise solution that sets up a digital thread to lower the cost of scaling up the use of 3D measurement data. The PolyWorks digital ecosystem — comprising a universal 3D metrology platform to deliver 3D measurement data to engineering and manufacturing teams in real time — accelerates the design, development and validation of products and manufacturing processes. It also controls the quality of individual pieces and assembled products, and helps resolve manufacturing issues as soon as they occur.

CMM Programming Software Features Five-Axis Infinite Positioning

Verisurf Software Inc. highlights how its coordinate measuring machine (CMM) programming solution with full-featured CAD enhances CMM pathing to optimize both programming and cycle times, making features like five-axis CMM infinite positioning more productive and cost-effective.

Infinite positioning is an aspect of five-axis CMM probing technology that provides increased productivity, greater flexibility in job setup and more optimized use of the CMM’s working volume.

Read Next

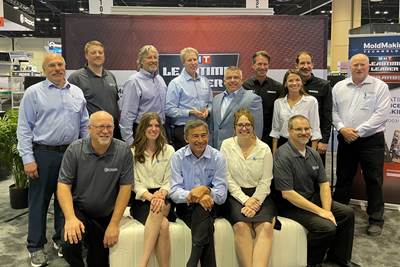

Dynamic Tool Corp. Wins MoldMaking Technology’s 2024 Leadtime Leader Award

Dynamic Tool Corp., a provider of engineered tooling solutions based in Menomonee, Wisconsin, has been awarded MoldMaking Technology’s prestigious 2024 Leadtime Leader Award. The announcement was made during a live awards ceremony at the Plastics Technology booth, where owners Steve and Ken Eberle accepted the award on behalf of their team.

Read MoreDeliberate Mismatches for Easier Mold Manufacture and Improved Part Appearance

Basic principles for applying deliberate mismatch in the area between the core and cavity and between two matching plastic parts.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)