CAD/CAM Software Suite Enhancements Optimize Machine Tools and Molds

Latest hyperMILL 2021.1 CAD/CAM software suite updates offers several innovative features for efficient 3D, 5-axis and mill/turn machining

Share

Read Next

Interactive Toolpath Edit. All photo credit: OPEN MIND Technologies USA Inc.

OPEN MIND Technologies USA Inc. developer of global CAD/CAM software solutions, has released its latest hyperMILL 2021.1 CAD/CAM software suite which offers users new and enhanced features for efficient 3D, 5-axis and mill/turn machining. Key innovations for more productive tool and moldmaking include a new “Interactive Edit Toolpath” capability which enables toolpath editing after initial toolpath generation. The feature is reportedly easy-to-use, and offers programmers the flexibility to adapt toolpaths by trimming and removing sequences accordingly for component conditions.

To streamline access to Product Manufacturing Information (PMI) and metadata, hyperMILL 2021.1 also offers a new import function that retrieves face quality information and metadata when importing CAD data from neutral or native formats. The data is then attached to the imported faces in hyperCAD-S, making the information available to hyperMILL and its machining processes.

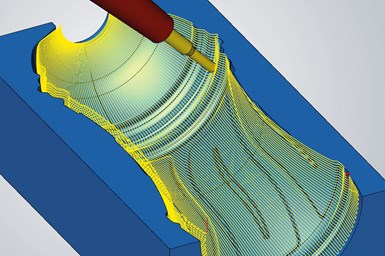

The 5-axis Radial Machining strategy allows bottle shapes and similar cavities to be easily and efficiently programmed in hyperMILL, resulting in high-quality surface finishes. Using a new radial projection method, toolpaths are calculated quickly so that the most productive machining strategies can be applied. For optimal high-precision machining, hyperMILL “High Precision Surface Mode” and “Smooth Overlap” strategies can also be applied when using 5-axis Radial Machining, ensuring the best surface quality and clean transitions.

For high-quality surface finishes and to simplify programming when flank and point milling blades, hyperMILL 2021.1 also offers several enhanced Multi-Blade strategies. According to OPEN MIND, any number of surfaces are permitted for the suction and pressure sides for easier blade surface extension. Fillets with a variable radius are supported in the latest version of hyperMILL. Further, for high accuracy, the enhanced Multi-Blade flank milling strategies result in smaller deviations on the suction and pressure side, and offer improved tool guidance along the upper boundary in the edge area.

OPEN MIND’s hyperMILL 2021.1 provides the integrated SIMULATION Center for generic NC data in turning and milling operations. Modeled after the hyperMILL VIRTUAL Machining Center, it is said to offer an intuitive operating environment for faster simulation, independent collision checking and extensive analysis functions.

Additional features in hyperMILL 2021.1 include an easy-to-use “XY Optimization” command for 3D profile finishing. In the hyperMILL Mill-Turn Module, the high-performance mode has been integrated into a 3-axis simultaneous roughing strategy, combining HPC and simultaneous turning. For the simplified alignment of components, hyperCAD-S has a new “Align Best Fit” machining command that allows like-geometry components to be aligned with one another using defined point pairs.

Related Content

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

-

Tolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.