CAM Software Optimizes Blow Mold Manufacturing

The hyperMILL software suite from OPEN MIND Technologies meets demanding blow mold requirements with automation processes, data import, efficient programming and NC code simulation.

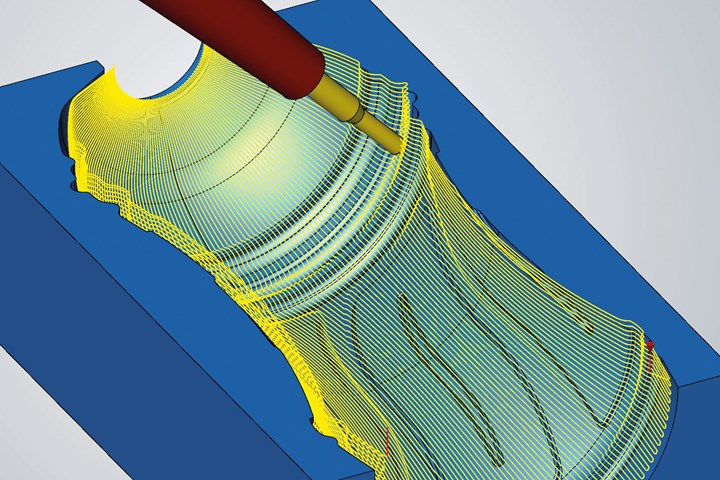

hyperMILL Radial Machining calculates toolpaths on CAD surfaces, producing high-quality surfaces ideally suited for blow mold manufacturing. Photo Credit: OPEN MIND Technologies.

OPEN MIND Technologies offers hyperMILL CAM software with five-axis radial machining strategies and other innovative technologies to optimize blow mold manufacturing.

From automation processes to data import, to efficient programming and NC code simulation, the hyperMILL software suite can reportedly meet demanding blow mold requirements such as optimized high-gloss surfaces and flawless transitions in all details. An integrated hyperCAD-S platform interfaces to all relevant CAD systems and provides comprehensive analysis tools and intuitive design functions. Partially or fully automated CAD and CAM process programming is user-controlled and interactive.

Offering precise rest material finishing and available as a 3D or five-axis strategy, hyperMILL enables the creation of efficient contour parallel toolpaths to reduce machining times. Also, efficient roughing strategies such as HPC, HFC and more, feature fast, stock-based toolpath calculation, according to the company.

A specially developed Radial Finishing strategy offered in hyperMILL also is said to optimize blow mold manufacturing. The radial projection method enables precise, efficient toolpath calculation on CAD surfaces using high-precision surface mode, resulting in high-quality surface finishes. Various machining strategies can be used to flexibly respond to existing component parameters. The five-axis inclination of the tool is controlled by simple tilt options, regardless of whether 3+2 or five-axis simultaneous machining is involved. Radial Finishing provides a constant 3D path infeed, smooth overlap for complete transitions and options for intelligent inclination.

Further, hyperMILL users have safe and reliable NC code simulation capabilities including toolpath analysis functions and automatic NC code optimization. hyperMILL VIRTUAL Machining also allows users to simulate, analyze and optimize the manufacturing process. The virtual rendering of the machine, combined with NC code simulation, enables exceptional levels of process control.

Related Content

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

.jpg;maxWidth=300;quality=90)