Design, Management Software Resources for Mold, Die Applications

As technology advances, so too do the options available to efficiently design molds or manage the data involved in their progress and production. Here’s a roundup of some of those solutions.

MMT staff continue to curate a list of relevant technologies in the form of roundups for readers to get a glimpse of what’s new and what’s improved. This month’s focus is software. Essential to design and build a more cost-effective mold, or determining the time and cost for a job or tracking its production, software has become a common tool used to keep everyday mold builders on track.

Software is also something that is constantly evolving. There are always new updates, better options with more features. In this way, it’s necessary to stay aware of what’s available. To learn more, read on.

To get an even bigger picture of tech on the market, check the “New Tech” section of the MMT website, where new posts are published daily. For more information on an item featured below, click the title link attached to each respective product, or visit that company’s website.

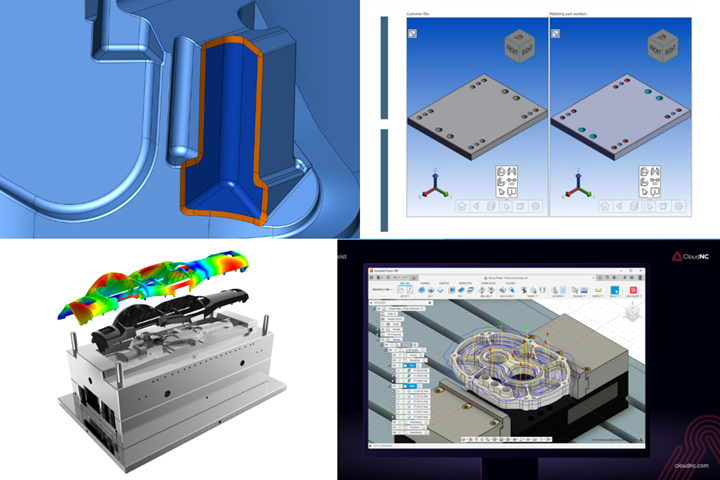

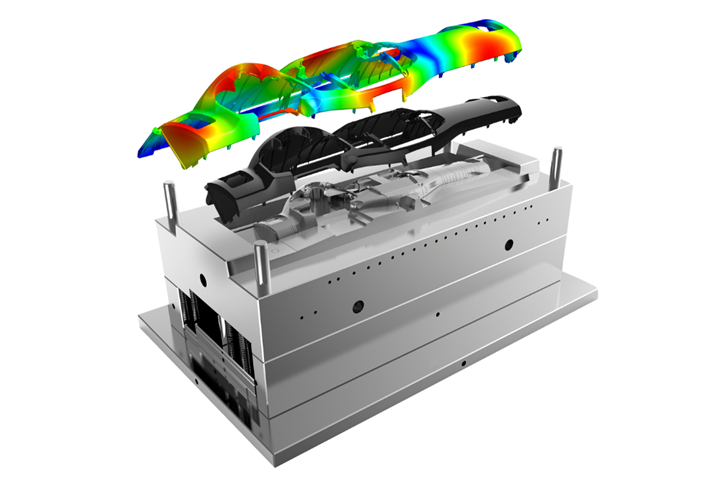

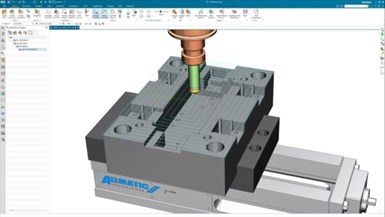

Optimized Five-Axis Machining Operations Guided by Moldmaking-Focused CAD/CAM Software

Source: CAM-Tool by CGS North America

In the dynamic landscape of mold and die manufacturing, CAM-Tool CAD/CAM software by CGS North America is refining the path to five-axis machining with enhanced ease and efficiency. The software’s features enable streamlined conversion of three-axis tool paths to simultaneous five-axis tool paths with a single click, eliminating the need for users to create new, time-consuming programs specifically tailored for five-axis machines.

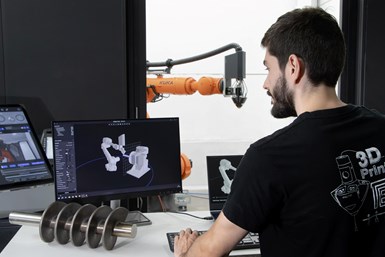

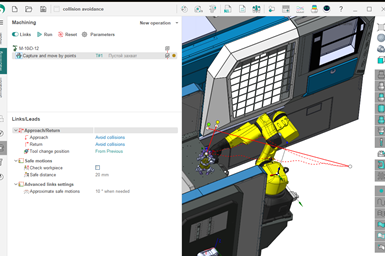

Robot Slicer Software Simplifies Wire-Laser Metal 3D Printing Technology

Meltio created the Meltio Space toolpath generator to facilitate the use of its metal 3D printing solutions. By offering a user-friendly interface and comprehensive features, this robot slicer simplifies the integration of Meltio’s wire-laser metal 3D printing technology — which can be used for the manufacture or maintenance of medium parts and molds — by offering a built-in robot library and postprocessors for some of the most popular robotic brands, including ABB, KUKA, FANUC and Yaskawa.

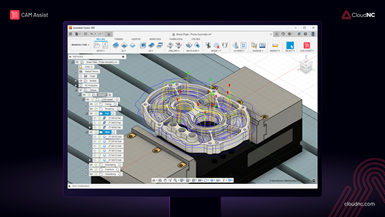

AI-Aided Software Accelerates CAM Programming Time by 80%

CloudNC, a manufacturing technology company backed by Autodesk and Lockheed Martin, is presenting its CAM Assist solution as a plug-in for Autodesk’s Fusion 360 software platform, enabling U.S. manufacturers to precision machine components more quickly and efficiently.

Robotic Programming Suite Introduces Enhanced Functionalities, Improvements

CAD/CAM/OLP developer SprutCAM Tech is releasing the 17.0.10 update for SprutCAM X, the company’s all-in-one CAD/CAM/OLP software suite for complex and creative robot tasks. This update introduces enhanced functionalities, bug fixes and improvements designed to streamline the user experience.

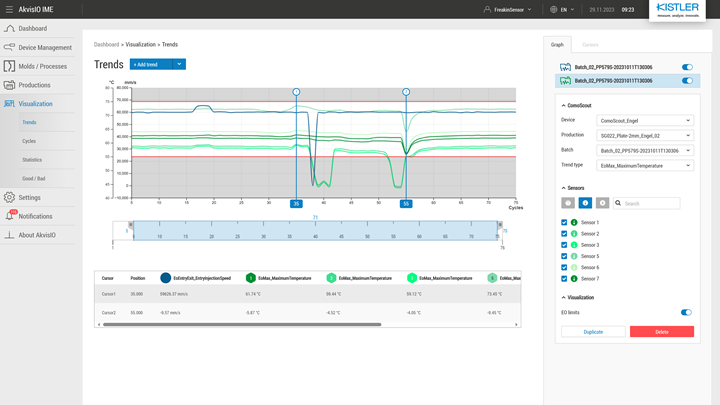

Machine Monitoring Enhances a Mold Builder's Automation Strategy

Scytec DataXchange, a machine monitoring software available through North American manufacturing integrator Shop Floor Automations, is a key component to a mold builder’s automation strategy to gain real-time visibility and manufacturing integration across all robots and CNC, fabrication, assembly and manual equipment on the shop floor.

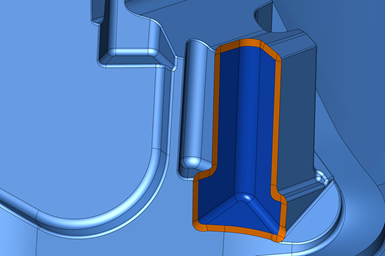

CAM Programming Efficiencies Streamline Mold Operations

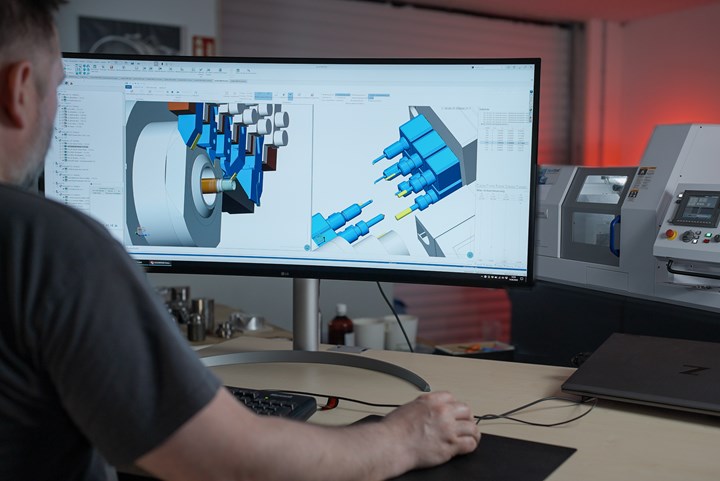

Source: Siemens Digital Industries Software

Siemens Digital Industries Software announces some update releases to its NX software for manufacturing for enhanced production. While this announcement covers NX CAM in particular, Siemens also offers updates for NX Additive Manufacturing , NX CAM On-Machine Probing, NX CMM Inspection Programming, Part Manufacturing Data Management, NX Line Designer and Fixture Planner, and NX Assembly Line Planner.

Related Content

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreTolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreRead Next

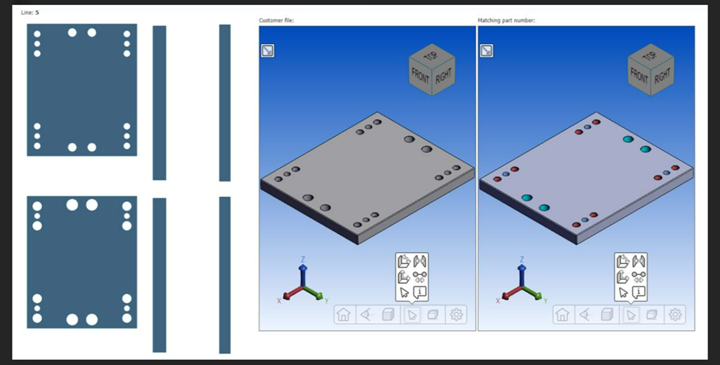

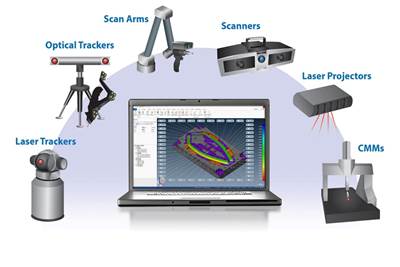

Software Strategy for Automated Mold Inspection

Consider inspection software with a CAD/CAM platform that supports model-based definition, works with all CAD files, and drives all fixed and portable CMMs.

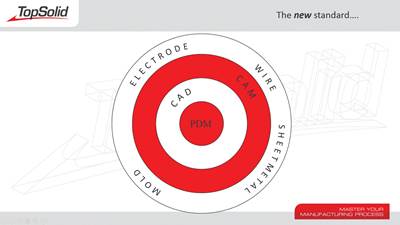

Read MoreManaging all That Data

Product data management may have a bad rap, but making it a priority rather than an afterthought can help make the most of your design and machining information.

Read MoreBalancing People, Process and Technology for Program Management Success

Using the expertise of its team members and emphasizing efficiency, this Michigan mold builder's process is designed to function as a highly efficient system.

Read More