Mold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production, including these latest mold materials and 3D printing technologies.

Share

Read Next

The injection molding process all starts with a metal mold. The type of material — whether it’s made of steel, aluminum or beryllium copper — used to make a mold is critical to the success of the final plastic part. The processes and technologies used to produce these molds are also just as pivotal.

Over the last few years, a focus on “next-generation” technologies has permeated the manufacturing industry — particularly regarding 3D printing and mold materials complementary to this process. Both material and process have quickly found a spot in mold building, whether it’s to aid in the production of an injection mold or even to repair it. Nonetheless, more traditional, high-quality tool steels also continue to maintain a key position for moldmakers.

Some of these developments are highlighted in the products roundup below. For a more comprehensive look at what is available to moldmakers, I encourage you to take a look at MMT’s “New Tech” section.

Sintered, Porous Mold Steel Eliminates Gas Buildup

Molder’s World Inc. draws attention to Vortex, a self-venting mold steel that it says is quickly becoming the industry standard. Specializing in self-venting mold steels since inception in 2001, Molder’s World is most well known as the preeminent distributor of Porcerax II prior to its discontinuation. Vortex, as its replacement, is claimed to be the most exciting development in the company’s 20+ year history.

Tight-Tolerance, 100% Recyclable Steel Plate Processing

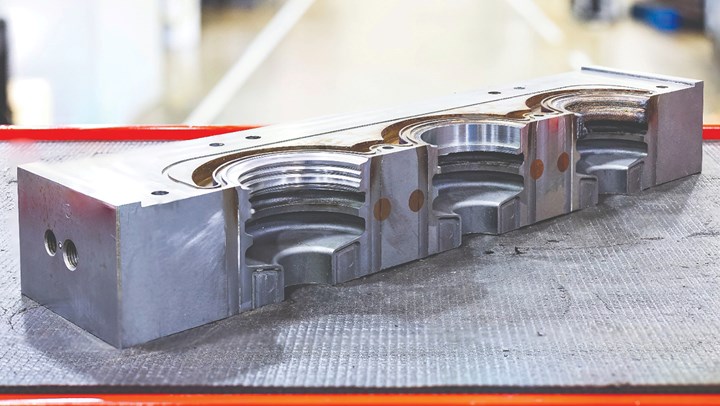

Steel 21 provides competitively priced A36 and 4140 grade steel plate for plastic injection and compression molds using its patented “21 Micro Mill” process. Steel 21 flame-crafts pin plates, clamp plates, ejector plates, manifolds and rails to customer data (dwg or stp files) using high-definition plasma through 2" thicknesses and oxyfuel through 8" thicknesses.

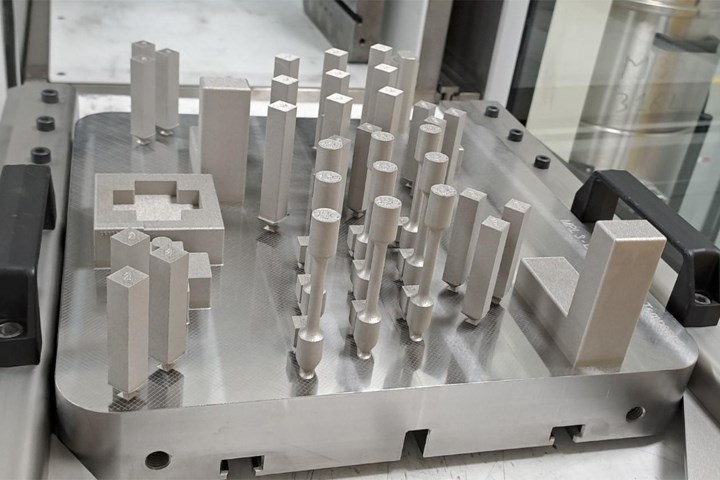

Hybrid Multitasking Five-Axis Brings Subtractive, Additive Processes to Moldmakers

For combined productivity, flexibility and profitability, Mazak’s VC-500A/5X AM HWD five-axis machine delivers hybrid multitasking and hot wire deposition (HWD) part processing for manufacturers, including those in the moldmaking sector. The machine combines additive processes and subtractive multitasking to reduce lead times and part costs while it increases machining accuracy and part quality.

Machine-Ready Blanks Help Mold Shops Reduce Production Time

Machine-Ready Blanks from TCI Precision Metals help mold shops shorten setup time, reduce scrap and reduce in-house machining time by eliminating material preparation for a cavity, core, mold blocks and other components. Made-to-order, machine-ready blanks are produced to tight tolerances and exact customer specifications; they are guaranteed to arrive machine-ready for production.

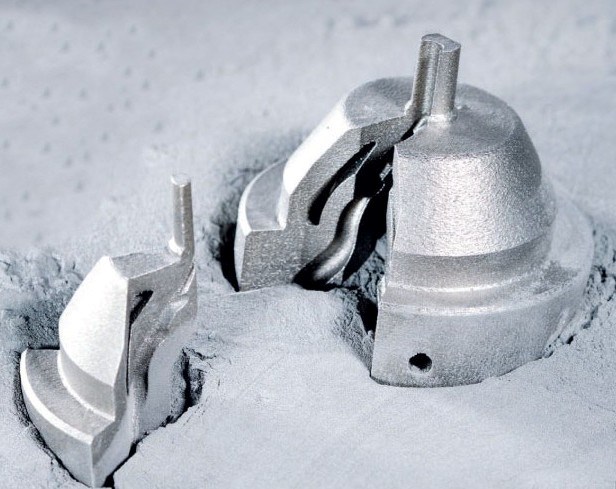

Tool Steel Improves the Efficiency of Molds, Injection Molding Using AM

AddUp will soon be releasing Printdur HCT, a tool steel optimized for injection molding that meets all customer requirements such as corrosion resistance, hardness and wear resistance for injection molding applications.

Related Content

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read More3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More