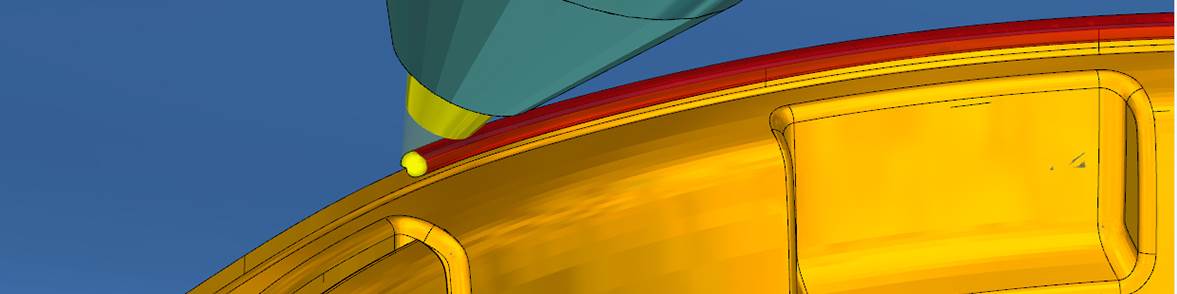

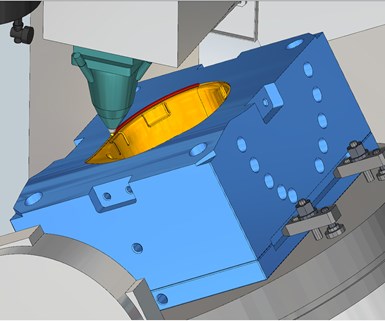

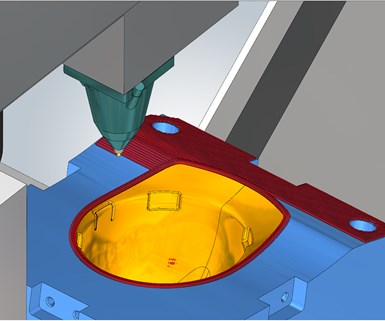

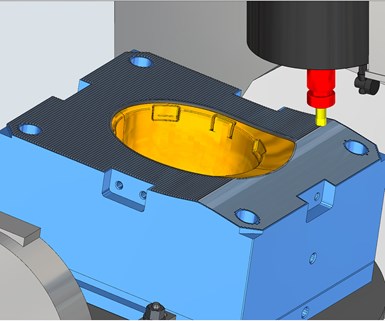

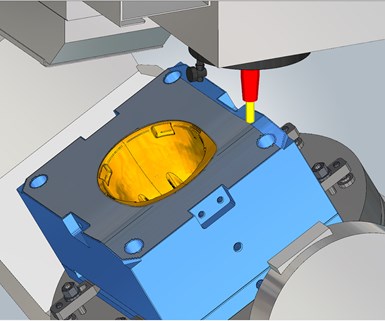

Directed Energy Deposition can be a great help during mold repair and the right CAM is essential. Images courtesy of Open Mind Technologies AG.

In manufacturing, “hybrid” commonly describes the combination of machining and 3D printing metal. Many hybrid systems comprise a milling machine or lathe equipped with a directed energy deposition (DED) head for depositing metal powder or wire.

DED is one of many additive manufacturing processes, but it is not new. At a high, abstract level, DED creates a melt pool and adds material to an existing component, such as welding two parts together. However, today we make DED new by combining it with subtractive machining and automating the process, which improves control and moves applications beyond welding parts.

It is easy to imagine the challenges manufacturers faced when they started to control the milling process using computers. After much development, manufacturers have learned a lot about this topic, and the knowledge base is now substantial. However, computer-aided DED processes are still in their first iterations, and manufacturers are in the discovery phase with much to learn.

Following is an overview of some hybrid AM applications, including mold repair, mold modification and composite molds. For each of these applications, the additive process will not necessarily happen on a flat area of the mold, which is where the DED process has an advantage over the powder bed fusion additive manufacturing process.

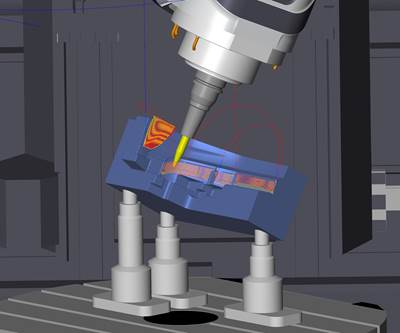

Mold Repair

Molds often have to be repaired or reworked during their production life, and the DED process can be of great help for this purpose. Adding material precisely where it is required and then re-machining the part in a single setup can now be achieved with one system.

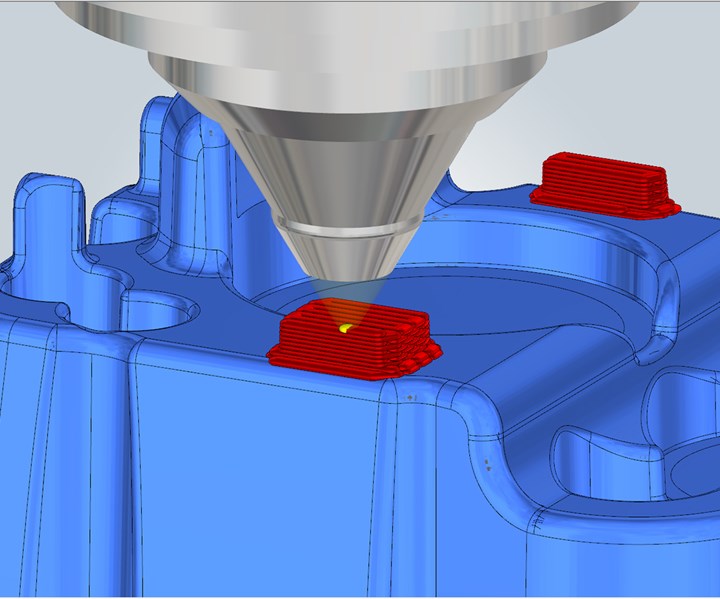

Mold Modification

Manufacturers are increasingly interested in modifying their old tooling to produce the next generation of parts after a design change.

DED to modify molds.

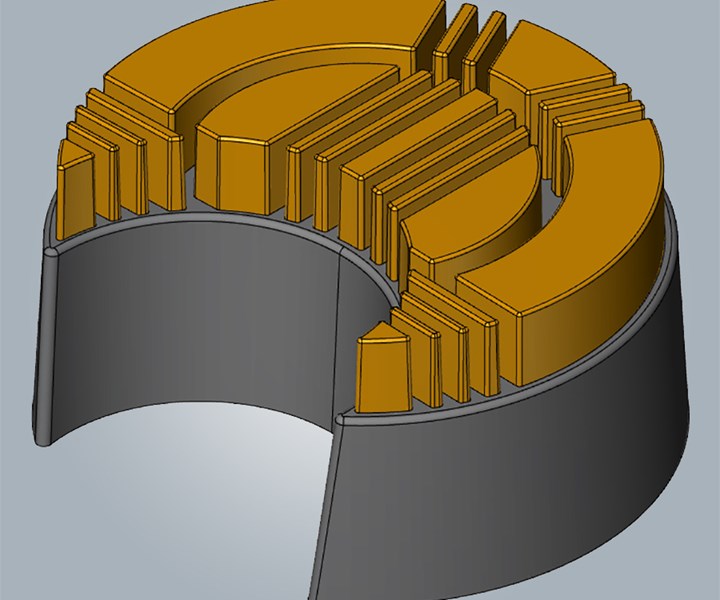

Composite Molds

Some manufacturers are starting to use the DED process because of its unique ability to generate a composite metal structure: one single part made of different alloys. For example, it’s possible to deposit material with high thermal conductivity properties on standard mold steel to reduce the part cooling time in the critical areas of the mold.

DED can generate a composite metal structure.

To get started, you must first establish the type of equipment that will incorporate the DED process. Machine tool manufacturers have started to offer dedicated machines for the DED process that also feature lasers and powder delivery systems for the additive process.

Software Solution

Next, and the focus of this article, is to determine which tools you need in your CAM strategy to properly support efficient hybrid processing with simultaneous additive and subtractive processing on one machine. For example, choose software that enables users to perfectly program cladding and milling together, true-to-detail additive and subtractive simulation and stock tracking between the individual process steps to guarantee the utmost reliability.

It is essential to answer these three questions before selecting programming CAM software for the DED process and to consider the following factors before you make your CAM purchase:

-

Is the software capable of working within a hybrid process?

-

Are you able to create machining and additive operations in the same programming environment?

-

Does the software allow for keeping track of the stock between different types of operations? The ability to generate stock is essential during an additive and subtractive process. It is used to contain the tool path and minimize motion in air, and also is used for collision check with the tool assembly. The stock condition is changing throughout the additive and subtractive processes of a hybrid operation.

Simulation: While it’s true that there is software specialized in simulation, it’s always better to have the part correct the first time as a result of working directly from CAM software, instead of going back and forth between CAM and simulation software. For example, when using additive manufacturing, the software should be able to display the build during the simulation to ensure that the process is building the workpiece correctly.

Some CAM software offering DED options are not offering this capability. This information should also be used by the CAM software to check possible collision with the additive device itself as well as with the machine component. This is especially important when performing five-axis motions during the build process.

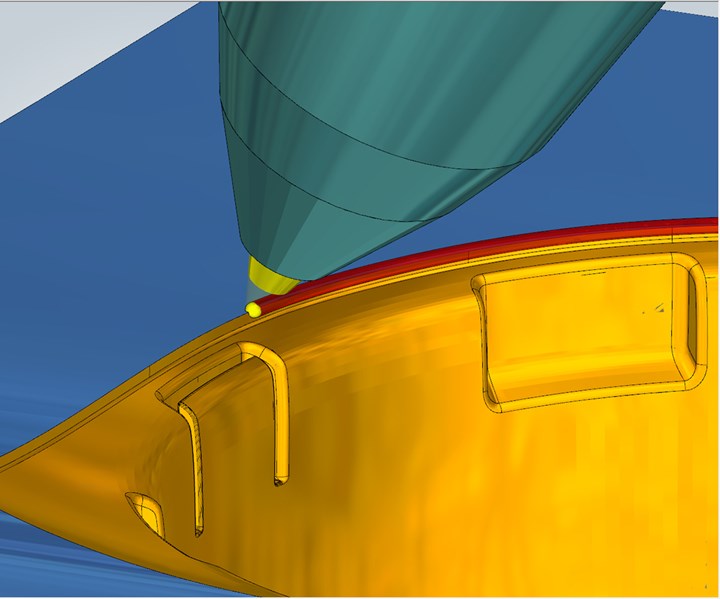

Five-axis machining: Five-axis machining capability is essential for the DED process because the deposition process must occur normal to the area on which the machine deposits the material. As previously mentioned, the DED process will most likely not happen on flat surfaces, so five-axis capability is vital. Another reason why five-axis is critical is that the additive device might need to be tilted to avoid existing features or to reach some areas.

The role CAM software has in the five-axis process is also very significant. While smoothness of the five-axis motions is a big factor in machining performance and part surface quality, it is also critical for DED because if the motions are not smooth, the machine will not be able to maintain its speed, causing the additive process to over-build or over-heat.

Post processors: All post-processor technologies are not the same. If you intend to perform complex five-axis motions with an expensive machine tool, you should work with a trusted solution that is proven to be safe, as there are enough variables associated with every new process. Also, ensure the post-processor is prepared to transport the DED technology information to the machine.

Lastly, carefully consider your software source. Since computer-aided DED is new, users might encounter unexpected issues, so it is essential to consult with a knowledgeable software supplier. Before choosing that supplier, ask about the team’s experience with additive manufacturing, assess their willingness to find solutions and inquire about existing partnerships they have with machine tool manufacturers who are involved in the research and development of additive technology.

Related Content

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreTips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreRead Next

Optimized Virtual Machining Enhances Mold Manufacturing

Virtual machining programs simulate computed tool paths as well as optimize machine tool capabilities and constraints, adding value to the computed tool paths.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)