CAD/CAM Software Generates Unique Additive Tool Paths for Mold Cooling Channels

The Open Mind hyperMILL Additive Manufacturing solution offers a variety of additive/hybrid functionalities, including toolpath strategies for designing intricate conformal cooling in a multi-axis machining setup.

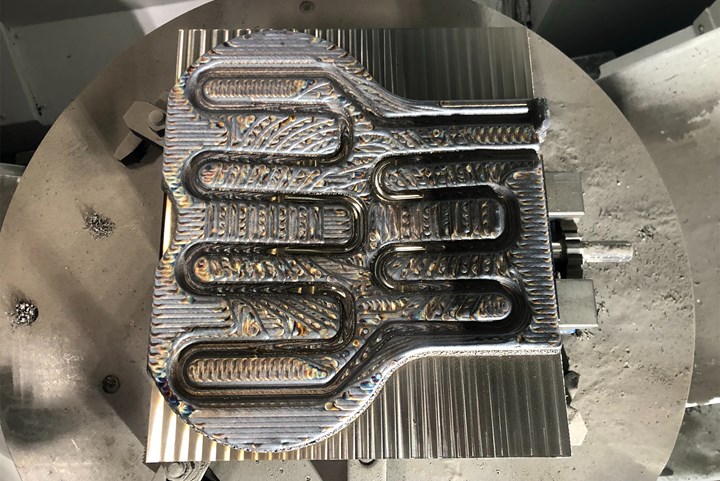

Mold and mold base for gas caps application with cooling channels shaped to be close to the part in a snaking pattern (tilted within the block). These cooling channels cannot be drilled, making additive manufacturing (AM) essential. Photo Credit, all images: Oak Ridge National Laboratory (ORNL)

Open Mind Technologies, a developer of CAD/CAM software solutions worldwide, offers hyperMILL Additive Manufacturing which has a wide range of capabilities for additive and hybrid processes, including the ability to create additive tool paths from all available toolpath strategies. This functionality is said to be exceptionally productive for directed energy deposition (DED) processes for additive/hybrid manufacturing in a multi-axis machining or robot delivery system setup.

Additive manufacturing provides a solution to incorporate conformal cooling channels to an injection mold screw.

A multi-axis application where having access to all available tool paths is a key advantage is when embedding conformal cooling channels into a mold, which are typically positioned at a uniform distance. Another use case involves designing geometric features (such as zigzags) to generate cooling changes that are not manufacturable by standard methods such as traditional deep-hole drilling techniques. Since powder or wire deposition needs to adhere to a base material, multi-axis orientation control is critical to building organically shaped channels, Open Mind notes. Furthermore, regarding hybrid platforms, final subtractive machining operations can occur in the same setup as the additive processes. This also enables the engineer to interleave additive and subtractive operations, which greatly increases the breadth of additive applications.

The images and video demonstrate two applications where hyperMILL Additive Manufacturing tool paths were used for creating conformal cooling channels in molds. The first example is a mold with multiple gas caps (opening image), and the second is an injection mold screw (at right). The assemblies, including the shaped channels, have been confirmed with metallurgical tests for material properties. The conformal cooling channels have also passed initial tests regarding fluid dynamics.

Related Content

-

4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

-

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

-

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.