Photo credit, clockwise (from top left):Tungaloy America, Tungaloy America, Walter USA and Arburg.

In order to acknowledge all of the amazing content we receive on a weekly basis, MMT has compiled all of its digital-only product/service items below for this month to keep your shop engaged in the latest and greatest products that are being offered in the moldmaking industry. This article covers cutting tools, additive manufacturing (AM), machining, software and inspection and measurement categories.

Missing out on the new and proven technologies and services we showcase in our print issues? Head on over here for the March print roundup (which primarily focused on cutting tools) or visit the “Magazine” tab.

Coating advances and optimized designs take tool life and changeover speed to new highs with YG-1 Tool’s new i-ONE system of exchangeable micro-grain carbide drill inserts and premium tool steel holders with coolant channels for maximized machining productivity and profitability.

The i-ONE line offers the advantage of a solid carbide drill combined with the flexibility of steel bodies via inserts that combine a new multilayered H-coating and optimized cutting angles with tool steel holders that retain Torx Plus clamping stability.

For manufacturers seeking solutions to unpredictable tool life and slow rough-machining speeds when working with heat-resistant superalloys (HRSA), Seco Tools has expanded its line of highly productive Secomax CW100 ceramic insert grades. Featuring new geometries for whisker-reinforced ceramic, Seco’s ceramic solutions are said to offer superior performance for challenging aerospace, oil and gas and power generation applications involving Inconel 718, Hastelloy, Waspaloy, MAR, Nimonic, Rene, Udimet and other HRSAs.

The Seco Assistant app from Seco Tools streamlines daily machining experiences, combining vital information and tools with a smooth user experience.

Seco Assistant’s machining calculator, for example, provides access to turning, milling and holemaking data for any brand including feeds, speeds and material removal rate.

Dormer Pramet’s versatile Pramet ISBN10 cutters are suitable for high feed milling, copy milling, ramping, helical interpolation, slotting and plunging. Its pocket design, in combination with the ANHX10 insert, also perform shoulder and face milling, offering what the company contends is a complete package for mold and die applications, from roughing to finishing.

A range of diameters are available from 0.625-1.500 inches. Multiple types, including parallel and modular shanks and shell mills are offered as well.

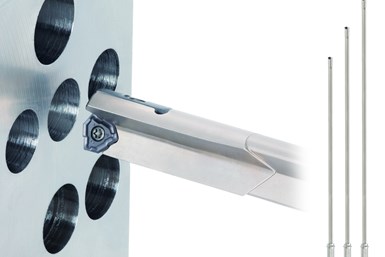

Tungaloy America Inc. has added 35xD, 40xD and 45xD drilling depth capabilities to its DeepTri-Drill indexable insert deep hole drills.

DeepTri-Drill is designed to provide productivity and application security for drilling deep holes on standard machining centers and CNC boring machines, while ensuring easy tool management by eliminating the need for regrinding. The insert features chip splitters that enable effective chip evacuations for high feed rates during deep hole drilling in various materials.

Tungaloy America highlights the expansion of its SpinJet coolant-driven, auxiliary high-speed spindle series to include the HPC SpinJet line which uses coolant pressures of up to 7 MPa (70 bar, 1,015 psi).

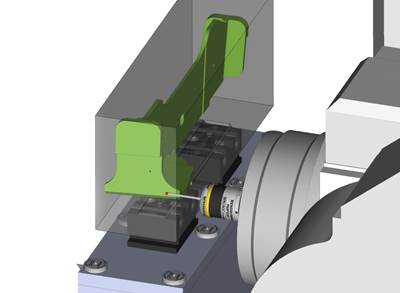

Easily adaptable to the spindle of existing CNC machines, the SpinJet provides instant enhancements in machining performance using small diameter cutting tools. No additional machine purchase or modifications are required; the SpinJet utilizes the machine’s existing through-spindle coolant supply as a pressurized power source to drive the internal turbine for cutting tool rotation, eliminating the cost and trouble of external air or electric power supplies.

Further extending the capabilities of high efficiency milling, Tungaloy America has expanded its MillQuadFeed high feed milling cutter series by adding new grades and cutter body options for its SWMT09 insert range.

They offer two options of insert geometries, ZER and UER that cover various high feed milling application needs including light cutting load at great depths of cut and the ability to provide the cutter with a small entry angle respectively.

Tungaloy has added new grades and geometries to its multifunctional TungCut line for grooving and parting-off tools. TungCut offers a wide range of insert and toolholder variations that provide customers with maximum performance in OD/ID grooving, face grooving, groove turning and parting operations. With strong and reliable insert clamping, Tungaloy says its TungCut guarantees minimum tool chatter, while providing maximum precision and tool life during heavy-duty grooving such as groove turning.

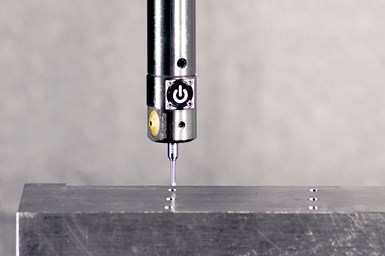

Big Daishowa Precision Tooling introduces the Nirox high-performance drill from Sphinx, the newest addition to its cutting tool lineup. Available in diameters from 0.30-3.00 mm, the Nirox was developed for use at low cutting speeds in unstable environments. The Nirox geometry has a degressive helix angle equal to 30 degrees at the point and is designed for accurate and precise hole location up to 9xD.

Big Daishowa Precision Tooling Inc. is expanding its offering of digital boring heads to include head sizes down to the CKB1 modular tooling connection size, which means boring down to Ø.787 in. for Series 310 peripheral heads, and Ø.016 in. for Series 112 centric boring heads.

The new heads will feature the same boring ranges and accept the same accessory products as their standard analog counterparts, ensuring an easy transition to digital tooling for all applications.

Big Daishowa Precision Tooling has released two smaller sizes of the EWN Smart Damper precision boring heads, which eliminate vibration in deep-hole finish boring with a patented damping system. Big Kaiser says this is the first time the EWN Smart Damper has been available in diameters below 1.260 in., down to 0.787 in. The CK1 and CK2 heads have lengths of 3.937 and 4.921 in. respectively.

Big Kaiser’s modular CK/CKB system allows for versatility in the length of tooling combinations, up to a maximum of 10 times diameter and can run on nearly every major spindle interface.

The AB735 synchronized tapping adaptor from Walter USA compensates for axial movement and pressure during tapping, allowing users to increase threading productivity while simultaneously increasing tapping tool life. As the synchronization of a machine, (i.e., the rotation of the spindle in relation to the feed) is one of the main reasons for tool wear in thread production, the AB735 Walter offers a flexible solution which minimizes the axial forces that occur during this process.

Walter says its M2471 milling cutter is the first on the market to feature a double-sided indexable round insert with eight useable cutting edges. The company says the cutter’s technical features, sintered design and the eight useable cutting edges reduce cutting material costs by up to 20%.

This system’s 0.98” (25 mm) diameter with parallel shank or ScrewFit modular interface is suitable for face and copy milling steel, stainless steels and materials with difficult cutting properties.

Walter introduces WBK20 and WBK30, new CBN grades that bring higher levels of productivity and reliability to cast iron and hardened steel machining. Both new grades have edge-preparation designs further optimized for their target applications.

With its tipped configuration, WBK20 is said to be exceptionally wear resistant and well suited for cast iron or powered metal workpiece finishing.

WBK30 is ideal for heavy depth of cuts, roughing in cast irons, powder metals and exceptionally hard and tough applications.

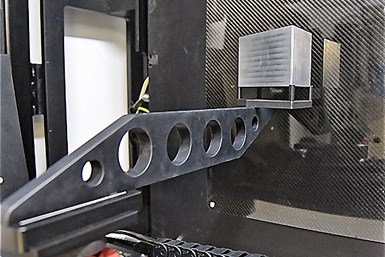

Walter USA showcases the Accure·tec AC001 vibration damping adaptor, a patented damping system for vibration-free milling when using long tools. Made specifically for shell mill mount milling cutters, the system delivers increased productivity and stability along with greater surface quality, improved tool and spindle life, and is ideal for deep pocket milling in operations at depths of up to 4xD.

According to Walter, Accure·tec delivers its advantages of longer tool life, higher productivity and greater process reliability at depths of cut up to three times that obtained with conventional methods. Internal coolant further optimizes chip removal.

Showcased during the Formnext Connection 2020 international exhibition and conference, Arburg’s Freeformer, an open system for the additive manufacturing of functional parts, combined with the company’s patented Arburg Plastic Freeforming (APF) process, is said to redefine plastics processing and meet demanding parts. Potential applications include medical technology, the processing of soft materials and polypropylene (PP) and additive manufacturing of multi-component parts.

A special plasticizing screw melts the standard granulates in the same way as in injection molding. This is followed by freeforming without the use of a mold.

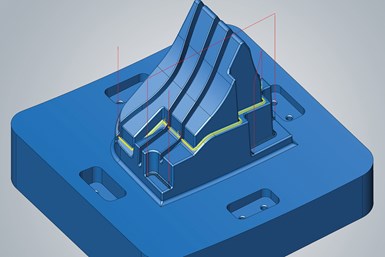

OPEN MIND Technologies USA Inc. developer of global CAD/CAM software solutions, has released its latest hyperMILL 2021.1 CAD/CAM software suite which offers users new and enhanced features for efficient 3D, 5-axis and mill/turn machining. Key innovations for more productive tool and moldmaking include a new “Interactive Edit Toolpath” capability which enables toolpath editing after initial toolpath generation. The feature is reportedly easy-to-use, and offers programmers the flexibility to adapt toolpaths by trimming and removing sequences accordingly for component conditions.

Tracer Interface, Burger & Brown Engineering has rebranded its Smartlink formerly called Tracer Bluetooth Interface. The company says the name more accurately describes the most commonly used application of the product to “link” with PC-based proprietary Data Logger software to collect, transmit and store injection mold cooling data from Tracer Base units. This data is used to confirm injection molded part processing conditions commonly required by medical, military or aerospace manufacturing of critical components.

Mitsui Seiki has launched a new series of CNC vertical machining centers called the “J” series for “Jig,” which are ideal to machine medical, optical, mold & die and aerospace parts.

The line provides positioning accuracy and repeatability of +/- 1µm. A thermal compensation system employs sensors on the machine faceplate and inside the spindle to minimize the effects of temperature changes on part accuracy and cut temperature-generated displacement by 60%. Z-axis thermal growth and deflection is also reduced by 30%. Cooling systems for slide way lubrication and ball screw cores stabilize axis feed precision.

Turnpwr, a control system from Heidenhain’s Acu-Rite brand, is designed for two-axis lathe machining where manual and automated operation are needed. The system is said to maximize throughput by reducing setup time, scrap and other non-productive operations by incorporating an easy-to-use conversational programming language.

Turnpwr includes both Acu-Rite conversational programming format, as well as G-code (ISO) programming. Basic editing of G-code programs is also possible.

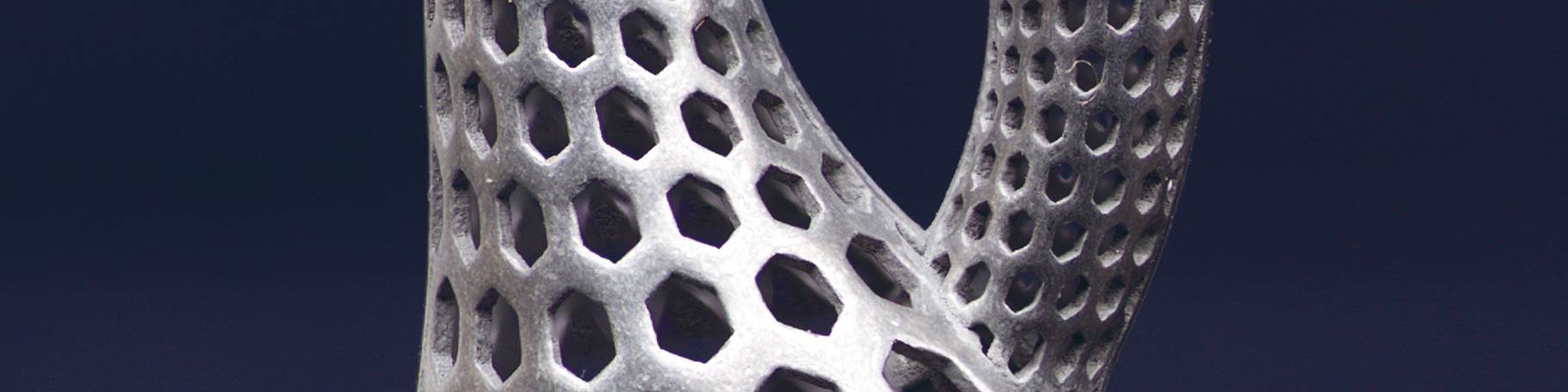

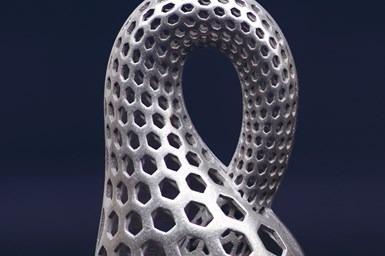

To meet the 3D metal printing market and its use of binder jetting technology—which uses an industrial printhead to selectively deposits a liquid binding agent onto a thin layer of powder particles—Digital Metal has expanded its portfolio to include DM D2, a tool steel alloy that is said to provide an effective combination of abrasive wear resistance and toughness. DM D2 is suitable for a wide range of applications, but most commonly for cutting and deformation tools.

According to Digital Metal, DM D2 is a versatile high-carbon, high-chromium D2 tool steel alloy that can be heat treated to high hardness and compressive strength.

Nikon Metrology’s Detector Evaluation Package offers users of Nikon Metrology's X-ray CT systems the ability to process check detector performance throughout service in order to meet stricter manufacturing safety/inspection standards. The kit is particularly ideal for companies that rely on CT to control product quality, or optimize production processes via Industry 4.0 initiatives.

SLM Solutions officially introduces its new SLM machine NXG XII 600, which is now available for commercial offer. Equipped with 12-kW simultaneously operating lasers, the 600 x 600 x 600-mm machine is said to be 20X faster compared to an SLM 280 Single Laser System, and is designed to be used in serial production for high-volume applications and for printing large parts.

Featuring a new optic system, the NXG XII 600 enables large overlap and is based on a tailor-made laser scanning system to best fit the build area.

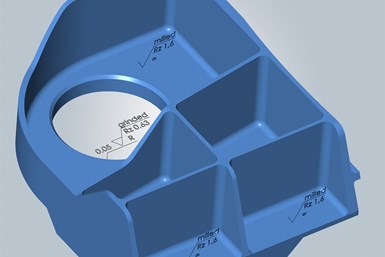

Integration Tech Soft 3D’s HOOPS Exchange, data access and reuse technology for manufacturing, architecture, engineering and construction workflows into hyperCAD-S and hyperMILL from OPEN MIND Technologies USA Inc. ensures that all CAD and product manufacturing information (PMI) data are transferred seamlessly between applications.

hyperMILL is a modular CAM solution for 2.5D, 3D, 5-axis, HSC/HPC and mill-turning processes. Including special applications and highly efficient automation solutions, the CAM software provides technology-geometry analysis and toolpath calculations.