Photo Credit, all images: Accu-Shape Plastics LLC

Accu-Shape Plastics LLC (Mohnton, Pennsylvania), a moldmaker and machine shop on the outskirts of Lancaster County, also known as Amish Country, offers engineering and design, general machining and mold manufacturing for lens lighting, food-safe containers, household products and more.

John Ervin Stoltzfus and his cousin Steve Stoltzfus, both Amish, established Accu-Shape in 2017 because they recognized a need for plastic injection-molded parts in the area. Beginning with two employees and one injection molding machine located in Gap, Pennsylvania, the company now has six employees with a goal to add more. Injection molding operations are in the original building, and a machine shop established in 2021 is located in Mohnton, Pennsylvania. Accu-Shape uses two diesel generators to power up the molding facility, and the machine shop is run on a single 120-kilowatt diesel generator and some line power.

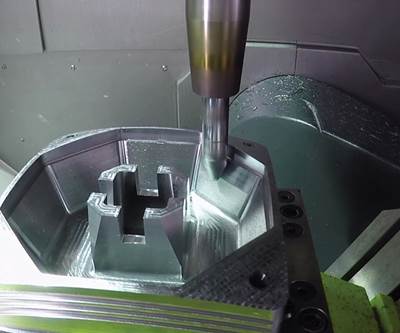

Accu-Shape is not seeking to be a large company. Instead, its team focuses on making the best-finished product to maintain top quality while increasing production and maximizing shop space. At first, they outsourced moldmaking, but in 2018, Accu-Shape brought in a three-axis vertical machining center to produce low-volume aluminum molds.

The three-axis machine was a step in the right direction, but the mold plates had to be machined on six sides, so it took six setups, and sometimes as many as eight, when tunnel gates had to be incorporated. The setup was laborious and not as accurate as they wanted. Parts typically have ±0.001 inch dimensional tolerances, so high surface finish quality is required.

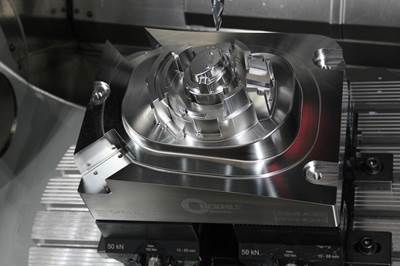

Accu-Shape Plastics is producing molds faster with more accuracy on the Grob G350 universal five-axis machine on the right.

Value and Versatility

Recognizing more efficient solutions for their machining requirements, Accu-Shape upgraded to a five-axis machine with some automation. John Ervin Stoltzfus contacted his local distributor, Jones Kinden Company, who introduced him to Grob Systems. The manufacturer of advanced CNC machining centers and automation recommended and demonstrated a G350 universal five-axis machining center with an automatic pallet changer, a 16k-spindle and a Heidenhain iTNC 530 control.

The G350 has a compact design, maximum milling performance and optimized work area access. Three linear and two rotary axes provide operators with five-axis simultaneous machining and interpolation, with a swivel range of 230 degrees in the A-axis and infinite rotation in the B-axis. The unique arrangement of the three linear axes minimizes the distance between the guides and the machining point (TCP), providing exceptional rigidity. In addition, a unique retractable spindle provides unmatched access to the workpiece, and even upside-down machining in a collision-free environment, ensuring the longest possible Z-travel path and optimum chip evacuation.

“The faster spindle is very helpful for machining small, intricate part geometry, including drilled cooling channels. We can machine molds whole without the need to machine half the mold and reassemble it afterward.”

“The Grob was way above and beyond any other five-axis machine we evaluated," Stoltzfus says. He saw tremendous benefit in using the maximum tool length and workpiece size simultaneously to accomplish deep-hole drilling, deep cavities and pocketing. A bonus is a horizontal design that efficiently evacuates chips.

The price point was attractive, too, considering the value the machine provided.

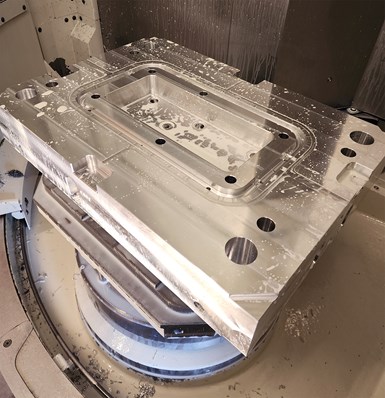

A 7075 aluminum mold plate ready to be unloaded from the pallet loading station on the Grob G350 five-axis machine.

Powering up for Precision

Before getting into full-swing on production, Accu-Shape and Grob had to address a key challenge. To power the Grob 16k-rpm spindle (which has a regenerative drive), the system needed to run on the 120-kilowatt diesel generator system, as the Amish strive to minimize the amount of electricity attained from the public grid. However, it took some ingenuity to bring the five-axis system up to its full speed.

At first, the spindle would wind down and stall the generator resulting in power loss. However, after consulting with the Grob team, Accu-Shape decided to use a load bank to capture the wave of energy coming back from the machine. Grob wrote a software program to address this issue, which showed some promise, but the load bank would not switch on quickly enough to capture the energy spike before shutting down the generator. As a result, the Grob machine could only reach 8k rpm. Then enters a solar and energy components company to configure a device that senses the spike and immediately turns on the load bank, bringing the Grob to its full speed potential at 16k rpm.

A plate for a mold producing a part that required multiple slides.

Five-Axis Accuracy, Speed

Once in production, Accu-Shape saved roughly four hours of setup time in a mold project with a large, slightly curved surface because they went from six to eight setups down to just two. Using a bull-nose corner radius end mill and tilting the work to keep the tool normal to the surface, cycle time to finish the piece was one hour and 12 minutes with excellent finish results.

Finishing the same feature on the three-axis machine using multiple ball nose end mills took about six hours with a lower quality finish. Stoltzfus notes the big-time savings and higher precision finish they achieved due to fewer setups, minimizing the possibility of operator error. “We have reduced setup times by 50% or more, and we save money with the Grob while also achieving excellent surface quality finishes,” Stoltzfus says.

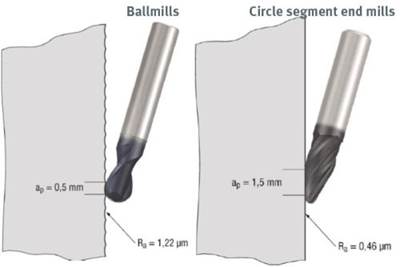

To maximize the new five-axis machining solution for some applications, Accu-Shape incorporated Emuge circle segment taper form end mills and hyperMILL software from Open Mind Technologies. “The cutters, in combination with hyperMILL, result in better, more precise finishes because we can use shorter tools giving us more control. Also, the circle segment tool design enables fewer passes to achieve the desired material removal and surface finishes, dramatically reducing cycle time,” Stoltzfus says.

The large radius on this mold core was finished utilizing Open Mind Technologies’ hyperMILL for CAM programming and Emuge circle segment end mills on the Grob five-axis machine, resulting in a 75% reduction in finishing time compared with the three-axis setup. The screenshot shows the Emuge circle segment end mill finishing the large radius on the mold core.

For example, Accu-Shape milled a mold core using hyperMILL for CAM programming and circle segment end mills on the Grob five-axis machine, resulting in a 75% reduction in finishing time compared with the three-axis setup. In addition, the planes were machined using a two-inch face mill with a 0.031-inch corner radius, and the radius was finished with a circle segment cutter. As a result, finishing time for the sides and the radius totaled just one hour and 11 minutes. The finishing time when milling the same mold core on the three-axis machine using a traditional ¾-inch ball nose end mill was four hours and 16 minutes.

“We have reduced setup times by 50% or more and we save money with the Grob while also achieving excellent surface quality finishes."

The Grob G350 is also faster due to its 16k-rpm spindle, whereas the three-axis machine only had a 12k-rpm spindle. “The faster spindle is very helpful for machining small, intricate part geometry, including drilled cooling channels. We can machine molds whole without the need to machine half the mold and reassemble it afterward,” Stoltzfus says.

Another benefit is the pallet changer, which loads a part while another part is being machined, providing Accu-Shape with unattended operations freeing up time for other work.

Outsourcing mold machining certainly has its place, but with the right machining technology and setup, the advantages of in-house production can be numerous. This is precisely the case for Accu-Shape.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreRead Next

Running Circles Around Milling Challenges

Circle-segment end mills can greatly improve five-axis mold prefinishing and finishing operations.

Read MoreBarrel Cutters Going Mainstream?

This CAM developer is gearing up to release a new toolpath strategy for new standard-issue, circle-segment cutting tools that promise big gains in tool life, surface finish and cycle time.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read More