Five-Axis Workshop Offers Advanced Strategies, New Products and Live Demos

Three companies collaborate to give attendees new approaches for achieving speed and efficiency in rough and finish machining.

Heidenhain Corp., Open Mind Technologies USA Inc. and Fraisa USA Inc. recently partnered to launch an education initiative that is expected to be made available throughout the United States. This initiative was kicked off with workshops on high-performance five-axis machining that feature experts from each company who provided insight into the best ways one can optimize roughing and finishing processes.

“Our first five-axis workshop was held at Fraisa’s facility in New Brighton, Minnesota, and the second workshop was held here, at Heidenhain’s Schaumburg, Illinois, facility,” Gisbert Ledvon, Heidenhain’s TNC business development manager, says. At Heidenhain, more than 30 people from several companies across the country attended the free, day-long workshop to learn more about the latest trends in five-axis machining. Multiple sessions covered various new and state-of-the-art five-axis programming strategies from Open Mind, Heidenhain motion control and CNC for five-axis machining centers and the newest circular-arc milling cutters from Fraisa, bringing the five-axis process chain full circle.

You must apply a different cutting strategy based on the type of CNC machine a shop uses.

With cameras in the CNC machines, live machining demonstrations in both roughing and finishing were presented in Heidenhain’s new Applied Technology Center during the workshop, providing visitors real-life examples of what complex machining can be done today with just the touch of a few buttons. “We utilized two different machining strategies: Dynamic Efficiency, which allows the machining center to automatically optimize speeds and feeds in variable workpiece thicknesses, on a Hermle C12, and Dynamic Precision, which improves mold surface quality and precision specifically on 3D toolpaths, on a KERN Micro Pro. These demonstrations gave participants the opportunity to see how two different machining methods using the Heidenhain TNC can achieve similar results,” Ledvon says. He explains that the Hermle has a stronger spindle (18,000 rpm) and is a little heavier-duty machine tool that is good for showing both rough- and finish-machining demonstrations, while the KERN has faster acceleration and deceleration speeds and a 42,000-rpm spindle, which was ideal for showing Dynamic Precision machining using smaller-sized cutting tools. “So, you must apply a different cutting strategy based on the type of CNC machine a shop uses. We showed the attendees how to choose the right combination to get the optimum results,” he says.

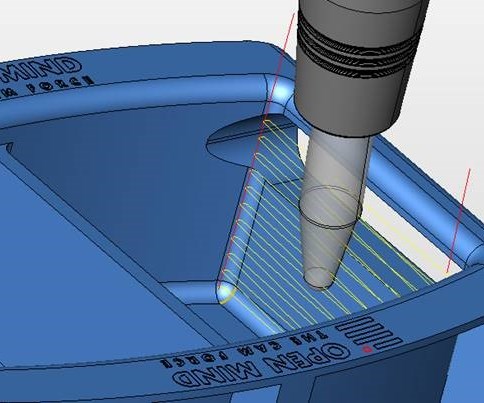

Alan Levine, managing director of Open Mind Technologies (Needham, Massachusetts), presented CAM technologies designed for users to take advantage of full, five-axis motion control and toolpaths for roughing and finishing. “Attendees were interested in the hyperMILL MAXX Machining finishing using conical barrel cutters and how to consider cost justification,” he says. “One moldmaker was interested in time-saving potential while maintaining surface finish.”

Mathieu Tapp, CEO of Fraisa USA Inc., says, “I think the main reason for most customers to attend was to see the barrel cutting in action. The main concern was that currently there are limited software options that enable the user to use the barrel tools the way they are intended. Fraisa worked directly with Open Mind when developing our tools and since they have a patent on certain software developments to use such tools, they are further along than most other CAM systems.” Tapp admits that often, customers are hesitant to change the software they use because of cost, but he says in some cases the time savings can be significant enough to justify the price of such a software in very short order.

Attendees were interested in the hyperMILL MAXX Machining finishing using conical barrel cutters and how to consider cost justification.

For roughing, Fraisa introduced its new high-performance end mills for multi-functional cutting (MFC). “These tools are multi-functional and not just designed for High-Dynamic or High-Efficiency milling, so they can be used in helical ramping, slotting, high-performance milling as well as High-Dynamic cutting to remove material the fastest way possible,” Tapp says. Fraisa also introduced a new line of barrel cutters for full, five-axis finish machining called the ArCut-X. These tools feature very large working radiuses which can save up to 90% in finishing time over traditional ball nose finishing.

Some takeaways for attendees as summed up by Open Mind’s Alan Levine are as follows:

- The larger cutter radius on the barrel surface enables larger step-down (typically 10x) and thereby results in large time savings.

- The time savings leads to broad benefits in the shop – better part delivery, increased machine availability, etc.

- The larger step-down leads to increased cutter life, because of the reduced toolpath distance for the cutter to cover the same surface, comparing to a ball endmill. The number of parts that can be machined with a given cutter increases in proportion to the increase of step-down (decrease in toolpath distance).

- The cutting process remains to use single-point contact, but the larger radius does increase the contact zone and generally a mildly lower feed rate is used for application of conical barrel cutters like the ArCut-X cutter.

- The tool path strategy can change the contact point on the cutter, spreading the wear during machining over a range of the cutter surface and increasing the cutter life.

- The tip of the conical barrel cutter (typically a spherical ball end) allows an additional usage for the cutter.

- Fraisa can regrind a worn conical barrel cutter (ArCut-X cutter) at lower cost than a new cutter, reducing the average cost per cutter.

Heidenhain’s Ledvon says that in addition to learning about new cutting tools and toolpath generation, one must also recognize the critical role that having a motion-control system that can generate the right speeds and feeds, as well as positioning accuracy of the five-axis (sometimes simultaneously), plays to maintain the right chip load on the cutting tool and to take full advantage of the toolpath the CAM system has generated, whether for rough-cutting or finishing.

Heidenhain, Fraisa and Open Mind Technologies expect to offer more five-axis workshops in other parts of the country, so be watching for announcements over the coming months.

Related Content

Tolerancing in Mold Design, Overcoming Cutting Tool Vibration, SPE MTD Updates & More Most-Viewed May Content

Every month, MMT draws inspiration from its diverse readership's wide-ranging interests, from mold design tolerancing to cutting tools and beyond. Here are May’s top 10 most-viewed articles, based on Google Analytics.

Read MoreCutting Tools: Technology to Make Your Process Easier

Having the right cutting tool technology for moldmaking is a crucial component for efficiency and cost-effectiveness.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreBuilding Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More