Photo Credit: (Top left) Heidenhain Corp. (top right) Emuge-Franken USA, (bottom left) Open Mind Technologies and (bottom right) Hasco America.

Creating high-quality, defect-free parts requires a variety of equipment, including machining centers, cutting tools and design software, as well as well-established inspection/measurement processes and automation/Industry 4.0 capabilities. The companies identified below offer just a few of many options available to the greater moldmaking community.

Note that this is only a small fraction of the products MMT’s editor posts. For those that appear online and in print, visit our “Magazine” found on the homepage.

For the full product post, click on each linked title, or find it under the “New Tech” section of the website.

Soraluce, part of Danobatgroup, the Machine Tool division of Mondragon Corp., introduces the Soraluce TA-D 25, a six-axis universal machining center. It is available with a 49" x 49" full contouring integrated B-axis rotary table, enabling a maximum part swing of 82" with maximum load capacity of 17,600 lbs. The Soraluce TA-D 25 is part of the company’s compact product line of bed-type universal machining centers.

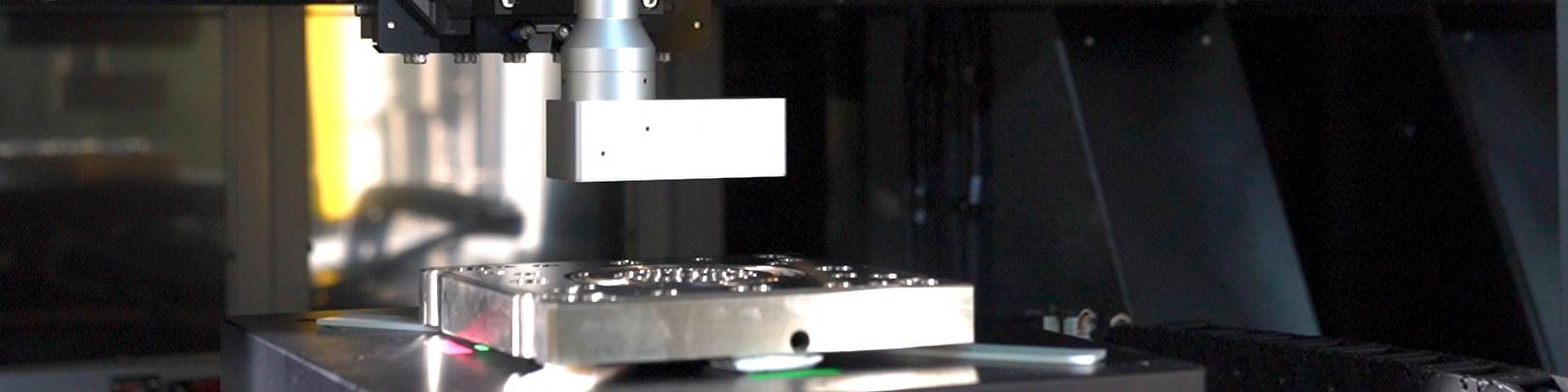

Photo Credit: Heidenhain Corp.

In answer to requests from machine tool users, Heidenhain Corp. introduces version 1.4.0 of its StateMonitor software platform enabling remote monitoring and data evaluation during real-time manufacturing. First introduced in 2019, the company notes StateMonitor has become an important option with its TNC controls to digitally connect and evaluate machine tool data on company networks as part of the Industry 4.0 initiative to boost efficiencies.

Walter USA has introduced the Xtra-tec XT M5004 octagon milling cutter, a versatile milling tool that combines productivity with stability. It can be used for face milling (roughing and finishing), ramping, pocket milling and circular interpolation, as well as chamfering and back chamfering of steel, stainless steels, cast iron, non-ferrous metals and materials with difficult cutting properties.

Photo Credit: Sandvik Coromant

Sandvik Coromant has launched CoroCut QI, a range of internal and face grooving inserts designed for smaller diameters. Optimized to enable a lighter cutting action and reduced cutting forces, CoroCut QI is said to ensure high-process security, reliable grooving operations and precise chip evacuation, resulting in high surface quality grooves.

Photo Credit: Ingersoll Cutting Tools.

The NuMaxHF line of new high-feed milling tools from Ingersoll Cutting Tools offers extreme ramping capabilities versus traditional high-feed milling tools, the company says. The thick, tangential insert features a diamond shape with a large inboard angle providing high feed rates and steep ramping angles.

Photo Credit: Emuge-Franken USA

Emuge-Franken USA has significantly expanded the range of Top-Cut VAR, the company’s multi-purpose, high performance end mills featuring a distinctive geometry and coating. The variable helix carbide end mills are effective across multiple job shop applications, including challenging production cutting operations.

Photo Credit: Hasco America

Hasco America has worked with various cooperation partners to produce a standardized color table (VDWF Guideline 2020-1) for mold and toolmakers to easily identify workpiece tolerances in 3D CAD design. Conventional CAM systems used in production are able to recognize the clearly defined colors and automatically derive tolerances. The table is available on the Hasco website.

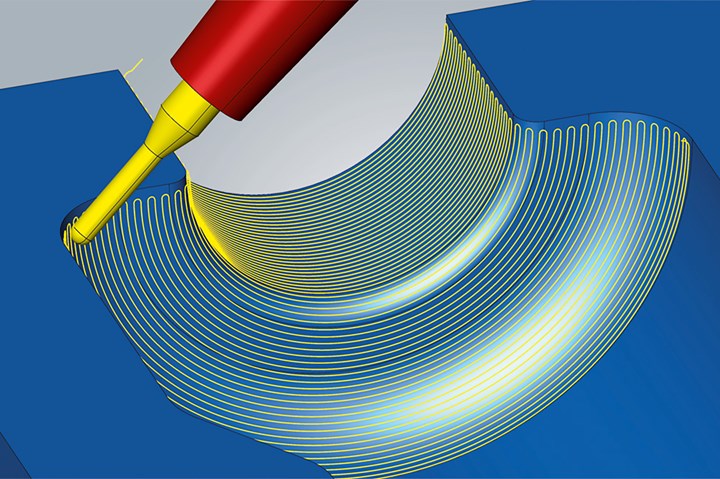

Highlights include a break-edge function for contour milling, combined pocket milling together with a finish path allowing cutter compensation and increased efficiency for 3D plane machining which now searches for suitable, high-performance path layouts according to parameters including when adaptive pockets are present.Open Mind Technologies unveils its latest hyperMILL 2022.1 CAD/CAM software suite which is said to give users increased convenience and faster programming tools in applications ranging from 2.5D to five-axis.

Photo Credit: Open Mind Technologies

Mitutoyo America Corp. adds EJ Counters and LG100 Series Linear Gages to its expansive sensor lineup of metrology products.

EJ Counters and LG100 Series Linear Gages are designed to be used inline or in measurement cells, and are said to enable real-time measurement and data management in any type of work environment.

Zygo Corp. announces the launch of the Nexview 650, a large-format metrology system designed as an inspection tool for the automated measurement of injection molding tooling, PCBs, glass panels and other samples requiring an extended work volume up to 650 x 650 mm. The system provides 2D and 3D measurements of a variety of surface features with sub-nanometer vertical precision and sub-micron lateral precision.