CAD/CAM Software Augments Machining, Data Feedback, Convenience

The 2021.2 hyperMILL update from OPEN MIND Technologies enhances virtual machining, additive manufacturing, 3D finishing and hyperCAD-S features.

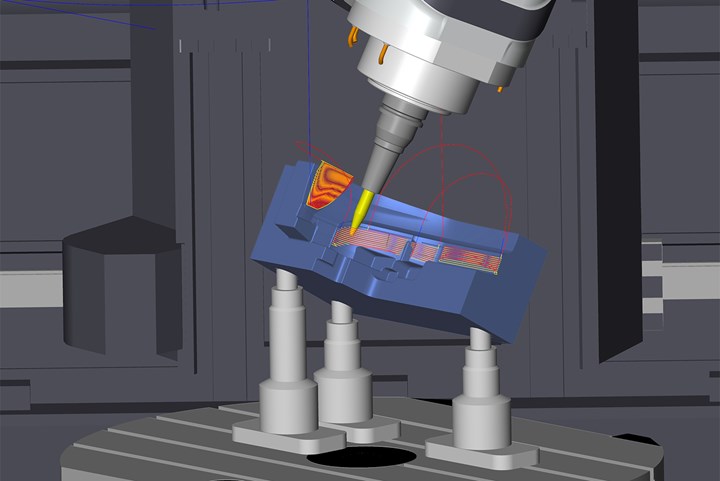

hyperMILL VIRTUAL Machining Optimizer now detects violations of the axis limitations and optimizes movement sequences accordingly. Photo Credit, all images: OPEN MIND Technologies USA Inc.

OPEN MIND Technologies, developer of global CAD/CAM software solutions, introduces its latest hyperMILL 2021.2 CAD/CAM software suite which offers users innovative and enhanced features for efficient, user friendly machining in applications ranging from 2.5D to five-axis (see 2021.1 updates). The updated version offers enhanced machining strategies, increased options for data feedback and more convenience overall, according to the company.

The software’s VIRTUAL Machining NC code-based machine simulation is one feature that has been enhanced, offering simplified programming and increased process reliability. Within the VIRTUAL Machining Optimizer module which links individual part programs with smooth and safe connections, the cutter is able to remain close to the workpiece, violations of the axis limitations are now detected and movement sequences are optimized accordingly. There is also a new option in VIRTUAL Machining to apply a special approach and retract strategy to machines where the cutting tool can be retracted into a tunnel.

Said to be a forerunner in CAM additive manufacturing (AM), OPEN MIND also introduces more capabilities in hyperMILL 2021.2 ADDITIVE Manufacturing including a Weave Mode. This new mode generates a toolpath in a wave-shaped or zigzag movement, to apply material to contours or to fill areas, allowing the application area to be widened and the thickness to be increased for the individual movement. This continuous application also improves the metallurgical properties of the applied material.

In the integrated hyperCAD-S CAD module, additional file formats for import and export have been added including SAT as standard ACIS text, and OBJ and 3MF for importing mesh data. Also, electrode creation has been improved via the optimized selection of the raw material. To support EDM machining, the hyperCAD-S Electrode Converter can now be used to create import files for several EDM machines such as Exeron, Zimmer & Kreim and OPS-INGERSOLL.

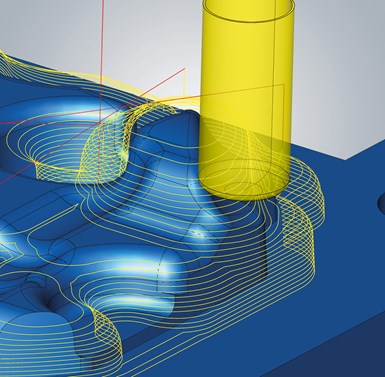

3D Z-Level Finishing enables machining with free tool geometry.

For increased quality and ease of use, enhancements to some CAM cycles are offered in hyperMILL 2021.2 such as 3D and five-axis Equidistant Finishing capabilities that define the milling area by selecting bounding curves so that individual areas on a surface model can be targeted. With 3D ISO Machining, multiple bounding curves are also able to be used to allow different areas to be machined in one job. In addition, 3D Z-level Shape Finishing includes several innovative features to improve machining quality, including optimized sorting of toolpath, smooth overlap at boundary, free tool geometry and trim toolpath to stock.

Finally, for improved clarity, hyperMILL 2021.2 also has new functions that reportedly provide better feedback during CAM programming. Automatic Stock Display displays stock automatically for any machining job. Also, there is a new Preview of Selected Entities feature that highlights entities such as curves, faces or points when a job is selected. And for component alignment, a new BEST FIT feature aligns the NC program automatically to the component position, eliminating manual alignment and optimizing the options offered by VIRTUAL Machining

Related Content

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.