Oerlikon HRSflow

920 74th Street

Byron Center, MI 49315 US

855-477-3569 | 616-228-6900

usa.hrsflow@oerlikon.com

hrsflow.com/ww/en

About Oerlikon HRSflow

We develop hot runner systems for the plastic injection molding industry. Our markets include automotive, logistics, environmental and more. Our business includes 1,000 employees, with headquarters in Italy, Michigan and Hangzhou. We provide customer support with 50+ service centers globally.

IS THIS YOUR COMPANY?

Video Gallery

Greetings from the former Managing Director of HRSflow GmbH and his successor.

The year 2024 will soon be history. We would like to take this opportunity to express our sincere thanks to all of you for the trusting, ...

Blood Conical Filter

Have you ever seen our MVP – Multi Valve Plate system in action? At Fakuma 2024, the Jestar medical demo mold running on the ...

Oerlikon HRSflow: Who we are

Oerlikon HRSflow is a part of the Swiss Technology group Oerlikon. Oerlikon HRSflow specializes in development and production ...

Sustainable Applications: the R-Box

Do you want to know more about our hot runner solutions for bio-based materials? Check out the video of this sustainable R-box!

As Seen On MoldMaking Technology

Oerlikon HRSflow Supplies the Following Products

- Hot Halves

- Hot Runner Manifolds

- Hydraulic Valve Gate Nozzles

- Pneumatic Valve Gate Nozzles

- Servo Valve Gate Nozzles

- Temperature Controls, Monitors, Sensors

- Thermal Hot Tip Nozzles

- Valve Gate Controllers

- Valve Gate Sequencers

Editorial, News, and Products

-

Recent Innovations in Mold Components and Hot Runners

In this most recent product roundup, MMT continues to offer a variety of innovative as well as tried-and-true technologies to benefit moldmakers.

-

Valve Gate Products for Technical Applications

Oerlikon HRSflow has developed new external valve gate end rings for the Tp and Vp nozzle series. The company also introduces its Through The Cavity (TTC) end ring for Tp nozzles.

-

Multi-Cavity Line Redefines Injection Molding Via Hot Runner Technology

Oerlikon HRSflow’s Multiflow HRS multi-cavity line is designed for the precise production of low shot weight parts, ranging from 0.5 to 120 grams. The multi-cavity systems offer key advantages, including fast cycle times, high production volumes, consistent part-to-part weight and the ability to process various materials, including PCR compounds and biopolymers.

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

From Design to First Shot: Technologies to Improve the Mold

In this most recent roundup, MMT has curated a variety of new or proven technologies that target the moldmaking industry that have been shared on the website this month.

-

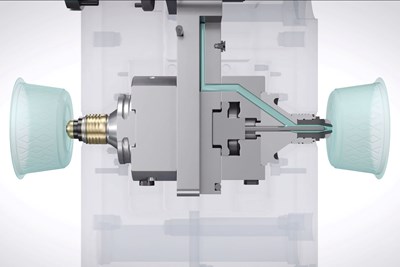

Stack Mold System Combines Fast Injection With High Process Repeatability

NPE2024: Primarily designed for thin-wall packaging applications, the patent-pending mold design by Oerlikon HRSflow brings consistency, simplified maintenance and assembly and a sustainable materials focus.

-

Moldmaking-Related Technology Highlights

This month’s tech roundup highlights mold materials and other miscellaneous technologies for moldmaking needs.

-

Product Innovations Pushing the Mold

Another tech roundup is here to provide an overview of technologies and services on the market for moldmakers. Featured in this roundup are cutting tools, mold components and more.

-

Hot Runner Cooling Design Lowers Energy Consumption, Maintenance

Oerlikon HRSflow says the HRScool Evo’s design eliminates separate, active water cooling for the hot runner pin’s hydraulic cylinder, reducing energy consumption by up to 10%.

-

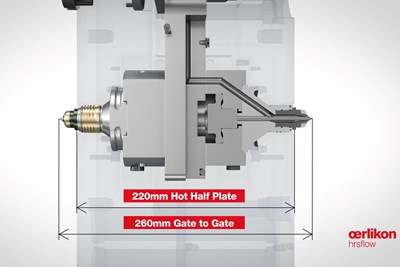

Compact Stack Mold for Thin-Wall Packaging

Oerlikon HRSflow says the patent-pending design allows the use of smaller injection molding machines while still promising the high output a stack mold tool.

-

Tolerancing in Mold Design, Overcoming Cutting Tool Vibration, SPE MTD Updates & More Most-Viewed May Content

Every month, MMT draws inspiration from its diverse readership's wide-ranging interests, from mold design tolerancing to cutting tools and beyond. Here are May’s top 10 most-viewed articles, based on Google Analytics.

-

Hot Runner Manufacturer Maintains Commitment to Production Planning and Quality Control

Two years later, the HRSflow facility in Byron Center, Michigan, still demonstrates workflow and quality on its hot runner manufacturing floor.

-

To the Next Level: Hot Runners, Mold Components Solutions and Services

Moldmaking can be a complex business, but things can be simplified with the right hot runner and mold component technologies and services.

-

VIDEO: Hot Runners and Sustainability

Oerlikon HRSflow North America Sales Director Robert Harvey breaks down hot runner technology that addresses sustainability opportunities and challenges.

-

Technology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

-

PTXPO 2023 Preview: Advancing the Mold With Featured Mold Component, Hot Runner Technology

There’s no doubt mold components and hot runners are important parts of the moldmaking industry. This preview gives mold buyers, mold builders and injection molders a look into PTXPO exhibitors displaying these technologies at the show.

-

Hot Runner Technologies Advance Quality Surface Requirements in Automotive

Oerlikon HRSflow hot runner systems combine cost-efficient production with a precise process control for a variety of automotive applications.

-

Multi-cavity Hot Runner Design Takes on Bio-based Material Challenges

Mold builder teams up with a hot runner supplier to develop a system configuration that produces an eco-friendly, attractive single-serving capsule.

-

Optimized Hot Runner Systems for PCR Compounds

Hot runner systems manufacturer Oerlikon HRSflow is developing new hot runner solutions to help create new products including fruit crates and home composting buckets.

-

Advancing the Mold With New Technologies

This roundup is full of products and services that help answer concerns and meet needs for the industry. Featured in this roundup are hot runners, mold components, mold materials and more.

-

Technology Roundup: The K Show Experience

Catch a glimpse into technologies for plastics, rubber, injection molding, hot runners, sustainability and more being showcased at this year’s K 2022.

-

Valve Gate Nozzle, Stack Mold Innovations Address Thin-Wall Injection Molding

Oerlikon launches the new Xp series of valve gate nozzles, engineered to significantly improve the overall aesthetic of finished parts, while patent-pending stack molds feature more user-friendly attributes.

-

Advanced Human Machine Interface Improves Hot Runner Control, Flexibility

FLEXflow hot runner technology from Oerlikon HRSflow has been thoroughly revised with new updates to the HMI 4.0 and access authorizations.

-

Advanced Hot Runner Solutions for Increased Injection Molding Flexibility, Sustainability

Hot runner solutions from Oerlikon HRSflow at K 2022 vary from hot runners tailored to small shot weights, Xp nozzle series, PCR- and biopolymer-specific hot runners and a flow simulation presentation.

-

Tips and Tricks to Retain Your Workforce

AMBA Conference 2022 presented a breakout session dedicated to determining what is and isn’t working when recruiting, hiring and retaining the next generation workforce in mold shops.

-

High-Performance Hot Runner Systems for Small Precision Parts

Oerlikon HRSflow’s new S Series nozzles offer a compact product with a reduced pitch for the production of increasingly challenging applications.

-

“Molds Make a Difference” at the Plastics Technology Expo

That was the sentiment of every person who came up to the MoldMaking Technology booth during last week’s Plastics Technology Expo to grab their giveaway “Molds Make” t-shirt after working the aisles seeking technology and process solutions and making new business connections.

-

Learn About Industry Topics and Emerging Technologies at PTXPO

Aside from being a great opportunity to network with other industry professionals, PTXPO will have numerous educational sessions about hot topics and emerging technologies.

-

Extended Process Window for Non-Cooled Hydraulic Cylinder Supports Temperature-Critical Applications

HRScool Evo, Oerlikon HRSflow’s optimized hydraulic cylinder system, has improved its insulation concept for uniform temperature distribution along the entire hot runner system, without the need for active liquid cooling.

-

Amerimold 2021 Post-Show Flashback: Build

MMT looks back on the return of an in-person Amerimold in September after a year-long pandemic.

-

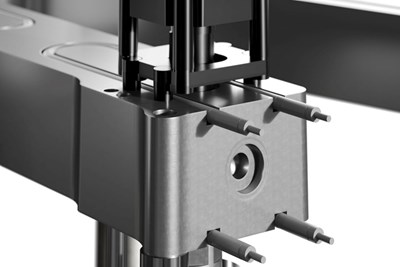

Mechanical Stroke Regulator for Hot Runner Systems

Oerlikon HRSflow’s mechanical stroke regulator (MSR) for hydraulic driven valve gate systems allows for easy pin adjustment even with hydraulic actuation.

-

Back Together Again at Amerimold 2021: Quality Conversations and Connections

The mold manufacturing community came together last week after a long two years apart, and it felt great! This slideshow is a very quick glimpse of everything from the show floor and technical presentations to the awards ceremony and networking party.

-

Advancing the Mold with Amerimold 2021 Education Sessions

With an expanded three day schedule, more free educational sessions are being offered than ever before, including a range of sessions from Amerimold exhibitors.

-

Oerlikon HRSflow Introduces S Series Line with Reduced Nozzle Pitch Size

Hot runner line’s compact design reduces nozzle pitch, plate thickness and offers more rapid color changes for the production of small technical parts.

-

Amerimold 2021 Education Sessions Are Here!

Gain expert insight and advice from 24 unique sessions that touch on all things related to the design, manufacture, maintenance and management of molds.

-

Booming Mold Manufacturing, Plastics Purchases Pave Way For Successful Amerimold, Extrusion and Molding Shows

Illinois’ transition into Phase 5 of its ‘Restore Illinois’ plan, which lifts all restrictions on gathering size, and favorable market news promises an unforgettable in-person plastics conference Sept. 21-23.

-

Networking at Amerimold 2021: Receptions, Happy Hour and Leadtime Leader Awards

Networking and making lasting connections doesn’t just happen on the show floor. That’s why Amerimold is bringing exhibitors and attendees three informal events for drinks, food and additional networking opportunities.

-

Compact Hydraulic Cylinder Enables Reduced Pitch

The newly released S Series Cylinder by HRSflow enables a minimum nozzle pitch of 37 mm and is suitable for technical materials.

-

HRSflow Demonstrates FLEXflo Evo Continuous Flexible Flow Control for Injection Molding

To outline the system’s potential in live demonstrations, HRSflow has produced three demonstration molds available to customers for trials, material tests and training.

-

Alba Enterprises Relocated NA Headquarters, Opens New Facility

New production, service and training facility in Loveland, Colorado, ramps up 3D modeling and mold sampling capabilities in order to deliver comprehensive, multidisciplinary guidance solving application needs.

-

Hot Runner Technologies Benefit Performance and Flexibility

HRSflow has developed advanced hot runner technologies like the precise HyFlow, the wear-resistant Hyper-GF and the flexible FLEXflow Evo film injector.

-

HRSflow Constructs New European Production Site

Designed according to lean manufacturing criteria, the new site will guarantee an increase in production capacity and gain more flexibility for HRSflow clients in the European market.

-

Servo Valve Gate System Advances Injection Molding Process Control

Electrically driven, HRSflow’s Flexflo Evo technology is a ready-to-install system, specifically designed to set and monitor the valve pin position during the injection process.

-

How to Use Servos and Sensors to Advance Process Control

A servo and sensor combination that makes the mold the machine presents opportunities to advance process control.

-

HRSflow is Global Market Leader for Automotive Hot Runner Systems

Since the fourth quarter of 2019, HRSflow has been the number one worldwide in the field of hot runner technology for automotive applications.

-

Pneumatic Cylinders Install Without Removing the Hot Runner

HRSflow announces its extended portfolio of compact and small cylinders which require limited installation space.

-

Connect & Learn at Molding 2020

With Molding 2020 only a couple weeks away, catch up on who will be attending and what you can learn from this educational conference.

-

Noteworthy News: Teaming Up

Catch up on the latest business partnerships within the moldmaking community from Hurco Companies, Inc., iD Additives, Inc., PCS Company, RJG and HRSflow.

-

Workflow and Quality Count

A recent visit to a hot runner systems and solutions provider proved the importance of workflow and quality to a production facility’s layout.

-

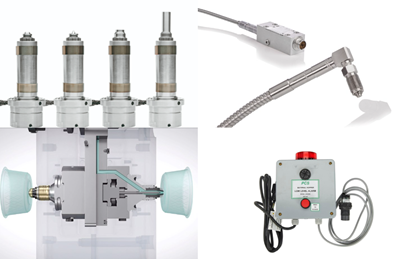

Partnership Advances Process Control Using In-Mold Sensors

RJG and HRSflow have partnered up to provide an advanced process control solution, specifically for servo valve gate technology or independent cavity control.

-

K Show Report: Next-Level Efficiency and Control

With a show as big as K 2019 with more than 3,000 exhibitors from 63 nations, you may think that identifying a theme among all the technology would be difficult, but after all is said and done, two words come to mind: efficiency and control.

-

Additional Control Unit Not Required for Hot Runner Technology

At K 2019, challenging state-of-the-art applications of HRSflow’s FLEXflow hot runner technology will be presented at several booths of partnering machine producers.

-

Hot Runner Technologies Improve Injection Molding Process

At K 2019, HRSflow will present challenging applications of its FLEXflow hot runner technology with recent developments targeted to improve the injection molding process.

-

Cylinder Design Eliminates Need for Water Cooling Actuators

The new HRScool cylinder design from HRSflow eliminates the need for water cooling of the corresponding actuator due to the twice optimized temperature management system.

-

Tech Trends: K 2019 Sneak Peek, Part 3

Not only will K 2019 be hosting discussions on hot industry topics, but it will be exhibiting products from exhibitors like HRSflow, CUMSA USA and Hasco.

-

Tech Trends: Runner Round Up

Take a look at some highlighted hot runner products, which can help your business’s production needs through shortened design and production times, warpage reduction, easy installations, varying levels of user controls and greater application flexibility.

-

Hot Runner Nozzles Suitable for Small Technical Components

HRSflow presents its small-sized SA series hot runner nozzles for injection molding small technical components with a very compact cut-out in the tool.

-

Family Mold Ensures Flawless Finishes

HRSflow presents its Flexflow technology family mold for one-shot production of three high-quality parts for a door module.

-

How to Better Balance Family Molds

A servo-driven valve gate can provide superior processing for family molds with significant variances in part sizes and volumes.

-

HRSflow Upgrades Service Center in Mexico

HRSflow relocates its Mexican service center to a larger facility.

-

2018 Technology Review and Sourcing Guide: Hot Runners

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including hot runners.

-

External Position of Side-Mounted Cylinder Eases Maintenance

If the side-mounted cylinders from HRSflow require maintenance, the maintenance technician can easily repair them without disassembling the mold.

-

Hot Runner Technologies Aim to Simplify Moldmakers’ Approaches

Hot runner suppliers are developing solutions that remove complexities from the way that moldmakers and molders design, control and maintain their processes.

-

Technology Tuesday: Hot Runners

In honor of this year’s supplement issue, this week’s Technology Tuesday blog features recent hot runner products.

-

Technology Tuesday: Products Featured at Fakuma 2017

More than 1700 exhibitors will showcase products at the 25th anniversary of Fakuma, an international trade show for industrial plastics processing. This slideshow highlights some of the products that will be on display.

-

Amerimold 2017: Plastics Exhibitors Promoted Products, Too

Amerimold had it all this year—or should I say it had MORE than ever before. While metalworking tools, materials and systems reigned supreme, the plastics side of the equation was also well represented.

-

Technology Tuesday: Hot Runners and Mold Components

This week’s Tech Tuesday blog brings readers a review of several products announced during the last few weeks, namely hot runner and mold componentry.

-

Technology Showcase, Hot Runners and Mold Components

Take a look at this week's slideshow to see products that make building and/or maintaining molds more efficient and cost-effective.

-

Improving Sequential Molding

For large injection-molded parts, a servo-driven valve gate system can improve surface finish and part performance.

-

Slideshow: Hot Runner Technology

Check out a few of the latest products in hot runner technology.

-

Energy Savings in Multi-Cavity Molds

Simplifying maintenance and energy savings in the development of hot runner systems for multi-cavity molds for medical applications.