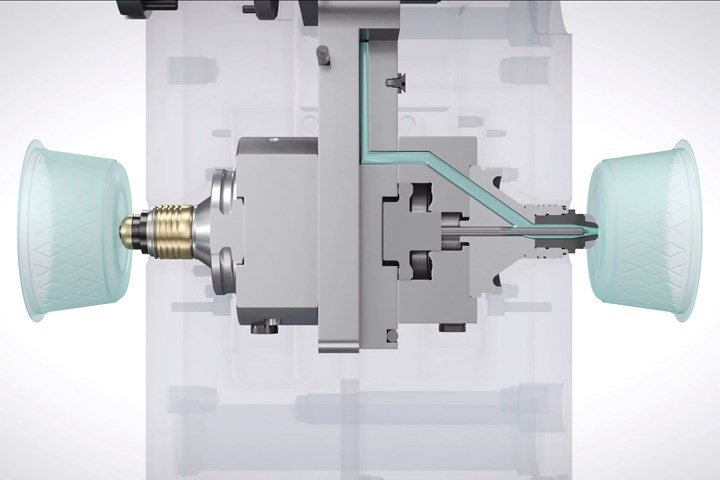

Compact Stack Mold for Thin-Wall Packaging

Oerlikon HRSflow says the patent-pending design allows the use of smaller injection molding machines while still promising the high output a stack mold tool.

The center plate of Oerlikon HRSflow’s stack mold fits a maximum hot-half plate thickness of 220 mm. Photo Credit: Oerlikon HRSflow

Hot runner manufacturer Oerlikon HRSflow has designed a patent-pending compact stack mold for thin-wall packaging applications. Designed to withstand high filling pressures for thin wall packaging applications, the system, which will be available soon, can be run on lower tonnage injection molding machines and is equipped with the company’s Xd nozzle series.

The design fits a maximum hot half plate thickness of 220 mm with a minimum distance between the gates on either side of the plate of 260 mm. In a video released with the announcement, Oerlikon HRSflow showed a four-drop design molding two 210-mL single-serving cups in recycled PP with a weight of 6.3 g and a wall thickness of 0.3 mm on either side of the middle plate. What Oerlikon HRSflow calls a “mosaic” design on the cups’ walls was patented by moldmaker Collomb and imparts robustness to the container despite the thin walls.

Related Content

-

Hammonton Mold, ADOP France Forge Strategic Partnership in Injection Blow Moldmaking

Hammonton Mold Inc., a leading full-service mold shop based in New Jersey specializing in injection blow molds (IBM), proudly announces its official partnership with ADOP France, a prominent IBM mold manufacturer based in Normandy, France.

-

R&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

-

MMT Chats: Injection Molds and Integrated Solutions Through Ambition and Innovation

Jordan Robertson, VP, Business Development and Marketing for StackTeck discusses various mold technologies to improve efficiencies in automation, cooling, lightweighting and sustainability.