Advanced Hot Runner Solutions for Increased Injection Molding Flexibility, Sustainability

Hot runner solutions from Oerlikon HRSflow at K 2022 vary from hot runners tailored to small shot weights, Xp nozzle series, PCR- and biopolymer-specific hot runners and a flow simulation presentation.

At K Show 2022, hot runner specialist Oerlikon HRSflow is focusing on an extensive range of hot runners tailored to small shot weights and the new Xp nozzle series for use in thin-wall injection molding. Both support the trend towards greater sustainability by helping to reduce energy consumption in plastics processing, according to the company. A range of hot runner solutions — from Oerlikon HRSflow and other companies — specifically designed for PCR materials and biopolymers are on display at the stands of several partner companies. In addition, the company, together with Engel and Borealis, are showing a presentation that describes the power of collaboration and simulation.

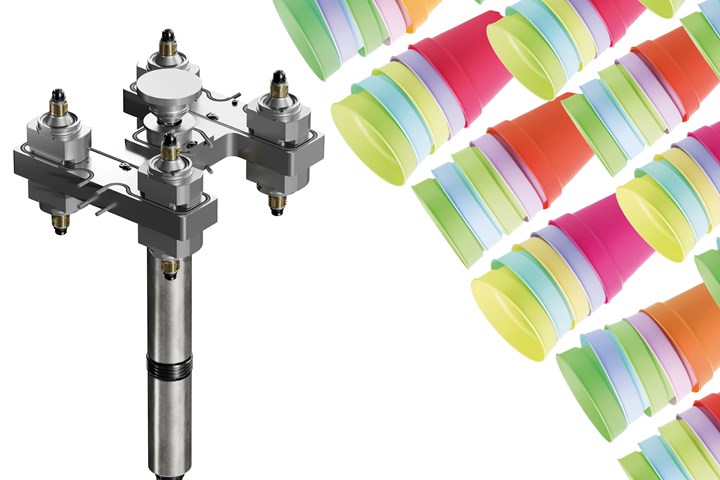

Oerlikon HRSflow has expanded its portfolio to include components for injection molding of demanding parts with small shot weights in stable and reliable processes. New, complete systems for this market segment include nozzles with small dimensions in all designs, from thermal gate to valve gate, as well as the associated manifolds and actuation mechanisms. For multicavity applications, a multi-valve plate (MVP) provides synchronized control of the injection channel across all cavities for high part-to-part weight consistency. Oerlikon HRSflow systems are said to offer optimal color change performance and easy system restart, reducing waste and increasing efficiency and sustainability.

The new low shot weight system line covers market segments such as medical technology, thin-walled packaging, beverages and home goods. The latest version of the system is reported to be highly reliable for processing even biopolymers and PCR compounds. A version with a specially coated nozzle tip is available for processing highly corrosive polymers including flame-retardant compounds. For demanding applications, Oerlikon HRSflow uses its in-house selective laser melting (SLM) additive manufacturing (AM) technology to produce cooling circuits for all market segments.

Another highlight is Oerlikon’s Xp series of valve gate nozzles, designed to withstand high filling pressures up to 2,200 bar and enable fast injection and cycle times in a stable process with high part weight consistency. Assembly is simplified and highly efficient thanks to a plug-and-play installation. This hot runner system, which enables the use of smaller injection molding machines, fits a maximum plate thickness of 240 mm, creating symmetrical systems with up to 8+8 drops to be supplied, with a minimum pitch between cavities of 65 mm and between nozzle and inlet of 120 mm.

A trend in automotive interiors are interactive panels controlled by touch sensors, whose elements and information only become visible when there is activity. For production in the In-Mold-Decoration (IMD) process, the FLEXflow hot runner technology with its servo-electric needle positioning is said to be the tool of choice because it enables precisely controlled, gentle and low-warpage overmolding of the sensitive electronic components with high-quality surfaces. The company also points to HRScool, its solution for hot runner injection molding, that eliminates the need for water cooling of the associated actuators. Both technologies help to reduce the environmental footprint of the injection molding process, Oerlikon says.

Oerlikon HRSflow has recently made the operating software for controlling the FLEXflow hot runner systems more intuitive and convenient. With the thoroughly revised HMI 4.0, systems with different nozzle types can be integrated and several parameter sets can be stored per mold. Extended possibilities exist for the individual control of the respective servo motors for nozzle needle positioning and for monitoring process stability. In addition, specific user accounts for individual access authorizations can now be set up and managed. Thanks to the web connection, access to the control unit is possible regardless of location.

A joint experience with sister brand, Oerlikon Balzers, ensures surface protection for all molded part surfaces to increase their corrosion resistance. One current application is BMW’s iXe all-electric SUV, which uses Oerlikon Balzer’s embedded PVD for Design parts (ePD) technology. This forward-looking, environmentally friendly coating process can be used wherever high-quality, metallic-looking surfaces on plastic parts with intelligent functionality are required, the company says.

Systems from Oerlikon HRSflow can be experienced live on the exhibition stands of Engel (Hall 15, booth C58, door panel and smart rear panel), Tederic (Hall 15, booth D40, 2K high-gloss B pillar), Arburg (Hall 13, booth A13 – B13, multicomponent tool box made of PC+ABS and Recopound, Haitian (Hall 15, booth A57, fruit box made of PE plus Tetra Pak recycled shredded flakes, Wittman-Battenfeld (Hall 15, booth C06, 3K coffee cup), Billion (Hall 15, booth B24, garden tool) and Netstal (Hall 15, booth D24, R-PP thin-wall cup).

During the show, Oerlikon HRSflow, Engel and Borealis will report at Oerlikon’s booth D10 in Hall 1 on a jointly realized project which, using a family mold with three different cavities, shows how close simulation and reality can be when partners contribute their know-how. Instead of the usual sequential approach, the partners performed each development step simultaneously, providing all relevant data of the injection molding machine, the valve gate hot runner system and the processed material for a perfect flow simulation. Compared to conventional sequential cooperation, the time until the initial sampling of the mold and for the commissioning itself was reduced as a result.

The K Show runs October 19-26, 2022 in Düsseldorf, Germany.

Related Content

Embracing ESG: One Mold Builder's Path to Sustainability and Success

The story of how a company in the moldmaking, injection molding and metal parts industry is navigating the challenges and opportunities associated with sustainability.

Read MoreVIDEO: Hot Runners and Sustainability

Oerlikon HRSflow North America Sales Director Robert Harvey breaks down hot runner technology that addresses sustainability opportunities and challenges.

Read MoreInjection Molds and Integrated Solutions Through Ambition and Innovation

Jordan Robertson, VP, Business Development and Marketing for StackTeck discusses various mold technologies to improve efficiencies in automation, cooling, lightweighting and sustainability.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)