Moldmaking-Related Technology Highlights

This month’s tech roundup highlights mold materials and other miscellaneous technologies for moldmaking needs.

Photo Credit, clockwise from top left: Walter USA, PCS Company, Oerlikon HRSflow and Hasco

Discovering new products and service solutions is made easy with MoldMaking Technology’s tech roundups. Each roundup aims to keep you in the loop of new developments and innovations that well-suited for your moldmaking operations.

Every month, MMT releases a roundup highlighting different products, processes and services. This month’s roundup has a focus on mold materials, but it is also full of miscellaneous highlights that MMT editors have shared on the website the past month, to keep you well-informed across the various categories important to this industry. Other technology roundups can be accessed here.

To check out tech from months prior, please browse the “New Tech” section on the MoldMaking Technology website. For more information on a product featured below, click the title link for the respective product.

Photo Credit: Alimex Precision in Aluminum

Cast Plate Aluminum Alloy is Suitable for Production Mold and Dies

Alimex ACP7 from Alimex Precision in Aluminum Inc. is a cast aluminum alloy from the 7000 series that is quickly gaining popularity among North American moldmakers. In the past, aluminum tooling was only used for testing and building prototypes, typically producing 50 to 1,000 parts. Today, especially with the 7000 series aluminum, it is used in production dies for 50,000 to 100,000+ shots

Solid End Mills are Suitable for Heavy-Duty Roughing Steel, Stainless Steel

Photo Credit: Sandvik Coromant

Sandvik Coromant is expanding its offering of CoroMill Plura HD solid end mills for heavy-duty roughing in steel and stainless steel with two new grades. This new generation of grades features the Zertivo 2.0 coating, which combines high productivity with an exceptional metal removal rate and high process security.

Photo Credit: PCS Company

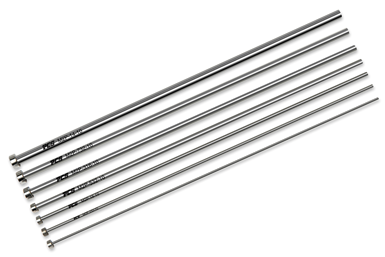

High-Speed Steel Ejector Pins for Plastic Injection Molds

PCS Company introduces M-2 ejector pins, an enhancement to its already extensive line of high-quality, precision ejector pin products for plastic injection molds. M-2 ejector pins are made of high-speed steel, which gives them higher wear resistance and better machineability than other currently available pins, according to PCS. Pin diameters range from 1/32" through 1/4" with lengths of 6" and 10".

Photo Credit: Oerlikon HRSflow

Hot Runner Cooling Design Lowers Energy Consumption, Maintenance

Hot runner supplier Oerlikon HRSflow has developed a hot runner injection molding system, HRScool Evo, in which the hydraulic cylinder that positions the pin does not require separate, active water cooling. Since the technology’s improvements announced in 2022, the company cites energy consumption reduction at the drops by up to 10%, depending on the system size and application.

Photo Credit: Boride Engineered Abrasives

All-in-One Mold Repair and Polishing Kit

Boride Engineered Abrasives has launched its first Mold Repair Starter Kit. This convenient, cost-saving, all-in-one repair and polishing kit includes a variety of the company’s most popular products to get users from start to final finish. Well-suited for beginner polisher and expert polisher alike, the Mold Repair Starter Kit comes in a portable, lightweight plastic case that can be carried directly to the mold for instant repair or neatly stored at a workstation.

Photo Credit: Zeiss Industrial Quality Solutions

CMMs Give Moldmakers Precision, Sustainability, Ergonomic Operation

A new generation added to the Zeiss Prismo family of coordinate measuring machines (CMM) raise the standards of precision measurement in terms of speed, flexibility, sustainability and productivity. Consistently focused on increasing efficiency without sacrificing measurement accuracy, Zeiss’ four devices deliver maximum accuracy at high measuring speeds thanks to a new definition of the scanning parameters, reduce the carbon footprint and enhance user safety.

Photo Credit: Kistler

Melt Pressure Sensor Takes Measurements Directly in the Nozzle

Kistler has introduced the Type 4004A piezoresistive melt pressure sensor, featuring a front diameter of 3 mm, which enables it to operate directly in injection nozzles and small extruders. In these spaces, it can measure both pressure and temperature in direct contact with the plastic melt, with potential applications in hot runner systems and additive manufacturing.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreMachine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

Read MoreRead Next

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreTechnology Roundup: New/Improved Technologies You Don't Want to Miss

With all the technology joining the market, moldmaking is a versatile, ever-evolving industry. As such, this technology roundup has no specific theme — it features a variety of products for applications and solutions across the industry.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More