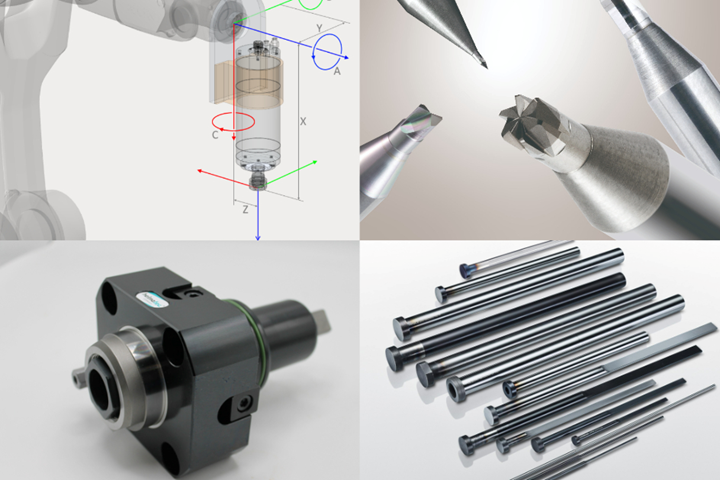

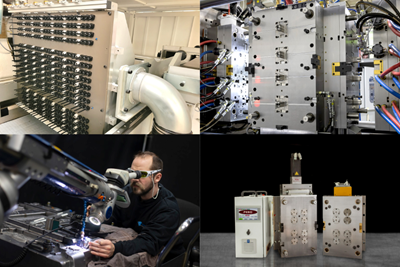

Photo credit (from top left, clockwise): SprutCAM Tech, Towa Corp., Hasco and Platinum Tooling

A new month, a new technology roundup! MoldMaking Technology’s compilations are a great way to stay up to date on new or improved products, processes, services and equipment. Each month, MMT staff curates a list of technology relevant to the industry to provide readers with a glimpse of what’s on the market for mold shops.

This month has no specific theme, offering a widespread view of innovations in the industry. It contains cutting tools, mold components, machining and more, from solid carbide end mills, process monitoring solutions and mold care to hot runner temperature units and portal measuring/inspection equipment. To find out the rest, you’ll have to read below.

To get an even bigger picture of tech on the market, check the “New Tech” section of the MMT website, where new posts are published daily. For more information on an item featured below, click the title link attached to each respective product, or visit that company’s website.

Cutting Tools

Walter has introduced the DC118 Supreme solid carbide drill. These 180-degree drills are said to differ from standard solid carbide drills by providing high rigidity against deflection, superior centering accuracy and four margins with corner chamfers, which enable guidance in challenging applications.

Photo Credit: Tungaloy America Inc.

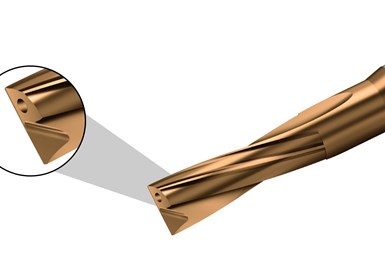

Tungaloy has introduced eight new barrel-shaped, solid carbide end mills to its SolidMeister series. The SolidMeister series offers a range of high-performance, solid-carbide, square-shoulder end mills, ball-nose end mills and high-feed cutters to provide solutions for rough to finish machining in any type of material, with high productivity and extended tool life.

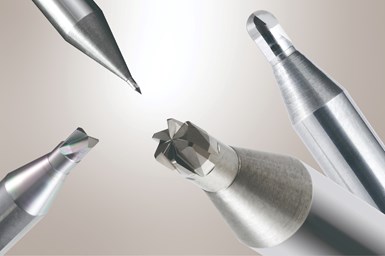

Towa has developed its own line of micro-diameter end mills and drills that feature high accuracy, with excellent wear resistance, sharpness and long life. The end mills, tipped with CBN, which is the second hardest material after diamond, are offered in sizes ranging from 0.1-6 mm in diameter, with various configurations — from sharp corner, radius corner, ball, standard neck length and extended neck length. Towa also offers CBN end mills in multi-flute configurations.

Walter USA’s solid carbide TC620 Supreme universal thread milling cutter features internal coolant and a multi-row design that is said to deliver greater productivity, permit less vibration, reduce cutting pressure and provide excellent dimensional accuracy.

Photo Credit: OSG USA Inc.

OSG USA introduces two series additions to its cutting tools product line that are advantageous for moldmakers, the AE-CR-MS-H end mill, and Phoenix PXM-PXSH exchangeable head end mill.

The AE-CR-MS-H series is ideal for the everyday mold builder because of the quality and longevity that can be achieved when cutting hardened steels above 50 HRC, according to the company. Phoenix PXM-PXSH is an exchangeable head end mill series designed for many materials typically seen in the mold and die industry — alloy steels, die steels and hardened steels up to 70 HRC.

Walter USA has expanded its solid carbide micro drill line with the addition of the DB131 Suprem micro pilot drill sizes and extended the DB133 Supreme micro drill offering to deep drills up to 30 × Dc. These new drills are said to be critical to achieving maximum process reliability combined with minimal dimensional variations and extended tool life in steel, cast iron, nonferrous, super alloys, hard materials and other materials (ISO P, K, N, S, H and O).

Mold Components

Photo Credit: Punch Industries

Punch Industry USA is a high-capacity one-stop shop that can outfit customer molds with off-the-shelf pins and custom mold components — including but not limited to — round pins, cores, cavities, full-stacks and threaded parts, ultimately freeing up a shop’s personnel for other tasks like building molds.

CUMSA USA is introducing a new concept of slide to the market with improved quality, lower costs and shorter production times. Available in six standard sizes that can accommodate a range of different strokes, the new slide is ideal for designers because of its design simplicity, mold builders for its easy installation and molders for the slide’s optimized maintenance.

Photo Credit: PCS Company, i-Mold

PCS Company is now distributing tunnel gate inserts in the U.S. from Erbach, Germany-based i-mold Molding Innovations.

Founded in 2004, i-mold (now Servomold GmbH) stands for innovative products and solutions for the plastics industry. The company’s focus is on tunnel gate technology and demolding. The tunnel gate inserts developed and produced in-house at i-mold are said to be renowned around the world as innovative products with high savings potential for moldmakers and injection molders.

A large number of ejector pins, sleeves and flat ejectors have been added to the extensive Hasco America product portfolio of ejectors for the functional demolding of molded parts from injection, compression and die-casting tools.

With more than 600 new, additional versions, Hasco says it offers its customers maximum flexibility and thus enables the individual selection of the right item for every application.

Machining

Photo Credit: Walter, United Grinding

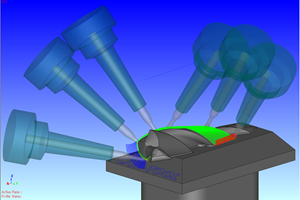

Whether producing complete cutting tools or regrinding, the Helitronic Mini Plus from Walter, a brand of United Grinding, is designed to fit customers’ needs as a cost-effective basic machine or as a fully automated cutting tool grinding system.

Photo Credit: DN Solutions

DN Solutions (formerly Doosan Machine Tools) introduces the DVF 4000, a smaller version of the company’s DVF family of vertical five-axis machining centers. The DVF Series is made up of compact five-axis CNC machines that are fully packaged to manage a customer’s diverse five-sided or simultaneous five-axis applications.

Photo Credit: Platinum Tooling

Platinum Tooling, an exclusive North American importer of Heimatec live tools and angle heads, has expanded its extensive line of tooling for the Haas BMT turret, a technology that provides a more rigid mounting configuration for toolholding.

The product line includes a variety of driven tools (axial and radial drilling and milling heads) as well as static toolholders.

Automation

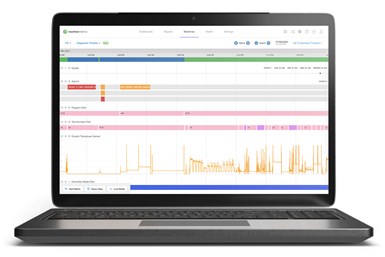

Photo Credit: MachineMetrics

MachineMetrics, a provider of machine connectivity and production analytics for manufacturers, is making its Connector available for Universal Robots (UR) to easily connect to and capture valuable data from any equipment from UR. This latest connector, now available through the UR+ program to all current UR cobot users, enables instant insights into the health and performance of its cobots.

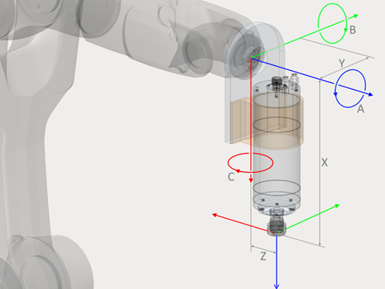

Tormach Inc., a supplier of affordable and compact CNC machines, introduces its latest product, the ZA6 robot. The ZA6 robot is built to industrial standards, utilizing EtherCAT servo motors, harmonic gear drives and aluminum castings. Requiring only 20A of single-phase 220VAC, Tormach says the robot can be installed almost anywhere.

Photo Credit: SprutCAM Tech

An update to SprutCAM Tech’s free Robot Calibration mobile app application now supports robots from 14 leading industrial robot manufacturers. The mobile app is designed to accurately calibrate the Tool Center Point (TCP) and automatically transfer the data to SprutCAM X Robot via a smartphone.

Maintenance, Repair and Surface Treatment

Photo Credit: Madison Chemical

Chemical formulator Madison Chemical introduces Ultra-Clean US-159, an alkaline detergent developed specifically for difficult cleaning operations involving the removal of aged, oxidized, burned-on oil and grease, including for mold maintenance. Intended for immersion including agi-lift and ultrasonic equipment, this formulation is said to clean more thoroughly in less time, thus increasing productivity.

When it comes to proper mold care, EcoAir Tool & Die Rust Preventative offered by Cortec Corp. is a cost-effective method for rust prevention.

EcoAir Tool & Die Rust Preventative is reported to be an easy-to-use injection mold protection spray that can be applied for corrosion protection of molding, tooling and dies. It forms a tenacious film on metal surfaces, repelling water and protecting against corrosive elements, as well as providing a degree of cleaning action.

Inspection/Measurement/Software

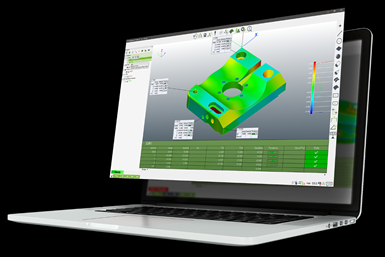

Photo Credit: NextMeasure

NextMeasure, a metrology software company, has launched a free universal 3D inspection software platform that is reported to be fast, reliable and compatible with all sensors and portable devices (e.g., scanners, measuring arms, laser trackers). The platform is ideal for analysis and inspection applications using measurement points and point clouds from a wide array of input formats and associated CAD files.

Hot Runners

Photo Credit: Oerlikon HRSflow

Hot runner technology enables injection-molded parts with the highest surface quality, as required in particular by the automotive industry. In many applications, systems from Oerlikon HRSflow support cost-efficient, material-saving production with highly precise process control, demonstrated through various project developments with partners.

The supporting element of a “smart” car rear panel using 2K technology is a frame made of polycarbonate (PC)/ABS.

For around 35 years, Hasco Hot Runner has been intensively involved in the further development of hot runner control units. The division offers a variety of different units for customized applications, including Basezone H1250, Clickzone H1270, Valuezone H1252 and Primezone H1281, all of which are identified by a high level of production reliability, control accuracy, user friendliness and long service life.