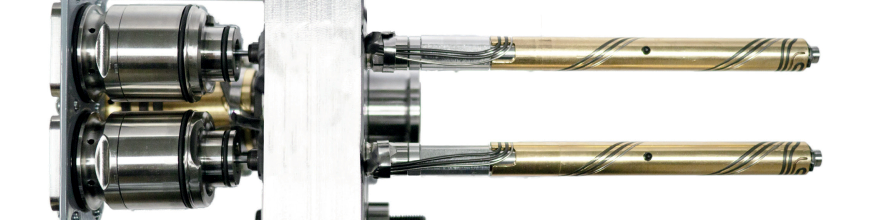

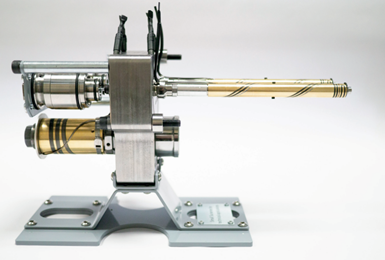

Oerlikon HRSflow offers a variety of hot runner technology, one of which MMT has covered a few times – a servo-driven valve gate system with controls that monitor the valve pin position and speed during the injection process (FLEXflow). But, instead of reviewing that technology, Robert and I talked about newer systems that address sustainability, specifically systems for part weights from 0.2 to 60 grams for the medical and packaging markets and nozzles for consumer products.

We also discuss other challenges the moldmaking and plastics industries are facing with recycled plastics and how Oerlikon HRSflow is solving those challenges.

For more video content from MMT, visit https://www.moldmakingtechnology.com/videos

Related Content

-

Embracing ESG: One Mold Builder's Path to Sustainability and Success

The story of how a company in the moldmaking, injection molding and metal parts industry is navigating the challenges and opportunities associated with sustainability.

-

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

-

Internal and External Factors Continue to Impact U.S. Moldmaking

Sustainable growth remains in the forecast as economic conditions continue to progress.