HRSflow Demonstrates FLEXflo Evo Continuous Flexible Flow Control for Injection Molding

To outline the system’s potential in live demonstrations, HRSflow has produced three demonstration molds available to customers for trials, material tests and training.

Photo Credit: HRSflow

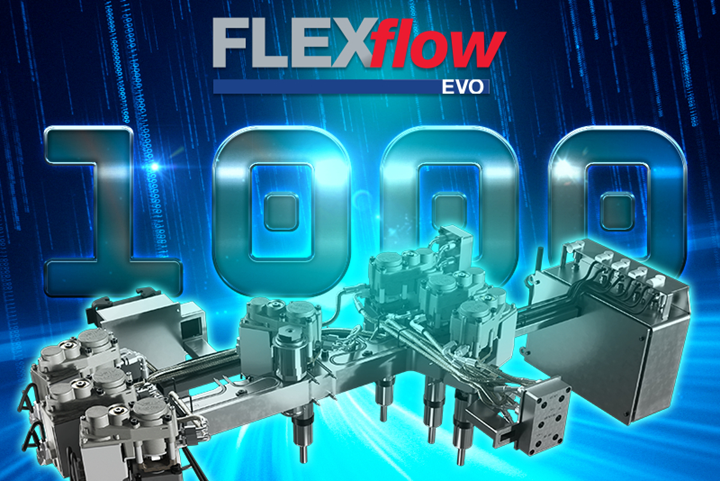

First introduced at K 2013, HRSflow (San Polo di Piave, Italy and Byron Center, Michigan) says its servo-driven valve gate system has proven its performance in many industries, including moldmaking, for years. Applicable to automotive engineering with lighting, interior, exterior and under-the-hood applications, electric vehicles and more, the company notes that it has now sold 1,000 units globally.

As part of its continuous development, HRSflow also recently launched its FLEXflow Evo injection molding technology, which features reduced space requirements (cutouts) as a result of optimized geometry. A flexible control system ensures easy adjustment of melt pressure and flow rate.

Moreover, to outline the potential of the system in live demonstrations, HRSflow says it has produced what is now the third family mold for the simultaneous production of elements of the interior door trim of motor vehicles. It reportedly shows how the filling process can be balanced and warpage largely controlled despite very different molded part sizes, something that has often been problematic with family molds. At the same time, says HRSflow, it demonstrates that the flow rate, which can be set independently and precisely for each cavity, reliably prevents overfeeding and flash formation. HRSflow has made the three demonstrator molds available to customers for trials, material tests and training at the company's headquarters in San Polo di Piave, Italy, at the plant in Hangzhou/China or at the plant in Grand Rapids, Michigan.

“Today’s automotive manufacturing environment is experiencing a transition phase towards a new direction: design complexity, e-car development, lightweighting and digitized driving,” says Maurizio Bazzo, president of HRSflow. “At the same time, Tier 1 suppliers and OEMs are looking for overall cost saving processes. To obtain the next-generation high quality parts and to reduce scrap rate the market will need increasingly flexible flow control for part molding optimization. HRSflow is ready to face this new challenge.”

Related Content

-

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

It Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.