Stack Mold System Combines Fast Injection With High Process Repeatability

NPE2024: Primarily designed for thin-wall packaging applications, the patent-pending mold design by Oerlikon HRSflow brings consistency, simplified maintenance and assembly and a sustainable materials focus.

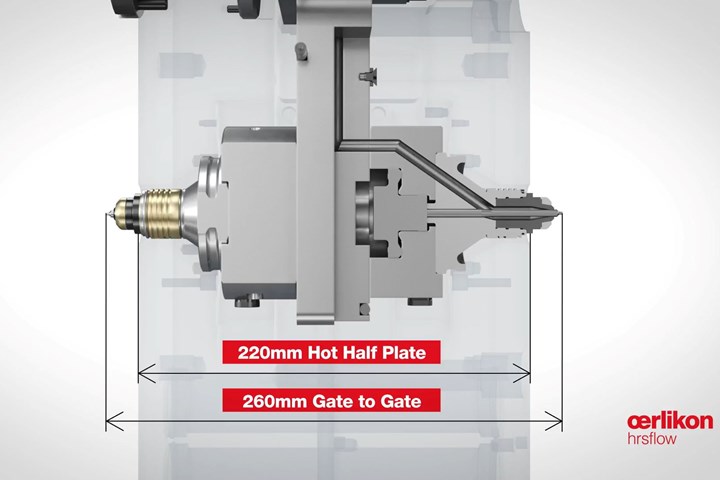

Oerlikon HRSflow has developed a patent-pending compact stack mold system that targets thin-wall packaging applications. It is equipped with nozzles from the company’s new Xd series, engineered to withstand high filling pressures. The stack mold system fits a maximum plate thickness of 220 mm. It is designed for fast injection and cycle times via a stable process with high part-to part weight consistency.

The stack mold’s design, with a plug-n-play system, enables a simplified assembly. It also offers fast and friendly maintenance, avoiding long and costly production line stoppage. The mold was also conceived to easily process PCR and sustainable compounds.

Oerlikon HRSflow aims for the best customer support, from rheological analysis and design phase to tryout and maintenance. For special applications, its team can define the optimal system configuration and predict part quality through advanced hot runner systems simulations. The company also prides itself in incorporating up-to-date technology and digitalization internally to increase its own efficiency, speed up response time to customers and a deliver a product of a higher quality.

Related Content

-

The Secrets to Hard Milling Success

The Secrets to Hard Milling Success

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.