Improving Sequential Molding

For large injection-molded parts, a servo-driven valve gate system can improve surface finish and part performance.

The art of sequential molding has proven to be a beneficial process in many markets. Automotive suppliers are one of the largest users of this technology, especially for the production of plastic parts with Class A surface finishes. Sequential molding is used to reposition or remove weld or knit lines from critical areas of the parts. These conditions occur when melt flow fronts collide in a mold cavity.

A poor knit line can cause cosmetic blemishes and significantly weaken the structural integrity of a part. In fact, strength at the knit line can be as little as 20 percent of the nominal strength of the part. Weld lines also can be visible after a part is painted and can cause wrinkles on in-mold-label injection-molded products. By sequencing the valve gate operation, knit and weld lines can be manipulated to more desirable positions within the molded part.

However, under certain conditions, visual imperfections in the form of flow marks or hesitation lines can still occur on the part surface between nozzles and/or near the gate itself even after sequential molding. Material flow hesitation is created by the very sudden change in pressures as melt from the first valve gate nozzle is introduced into the cavity at an initial high rate of velocity. As the material from the second valve gate nozzle enters the cavity, backfilling

can occur between the nozzle entry points. The quick initial pressure rise then dissipates, causing the hesitation mark.

This condition is typical in the operation of standard valve gate designs. The process technique can be adjusted to try to improve the outcome, but this is not always successful. Reposi-tioning the valve gate nozzles is another possibility, but this is both costly and time-consuming, since it requires mold rework.

In addition to lessening or eliminating surface imperfections, sequential molding can reduce the amount of clamp tonnage required to produce a quality part as compared to the amount required when filling a mold cavity through all gates at once. Pack and hold can be profiled with greater precision, supplying more intense packing to just those areas that require it. Family molds, co-injection, overmolding and gas-assist also can benefit from the use of sequential molding techniques.

The success of sequential molding also has been influenced by improvements to control technology in addition to improvements to hot runner technology. Better performance from heater and nozzle components have helped to improve part quality and repeatability. In addition, the introduction of cavity event devices such as pressure and temperature transducers have allowed molding technicians to fine-tune processes to produce consistent part quality.

Sequential injection has not, however, fully eliminated all molding problems and automotive manufacturers and other markets that supply large injection-molded parts are continuously demanding technologies that provide improved part performance and cosmetic appearance.

Servo-Driven Valve Gate System

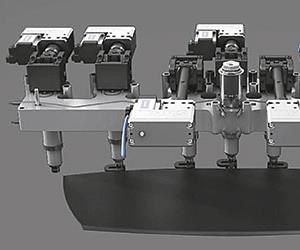

One innovation for improving sequential injection molding centers around the use of servomotor technology. Although this technology is not new for valve-gate operation, in the past, servomotors could typically only be used in small-part molding applications due to limitations in the size of available motors, which would be directly mounted at the top of the valve-gate cylinder. This standard mounting practice restricts nozzle positions to locations that often are not optimal for the part design. Also, the small motor size cannot overcome the plastic pressure realized on the face of a valve pin diameter that is required for large part applications. As a result, valve gate systems and the nozzle capacity commonly used to produce large injection-molded parts have required hydraulic operation due to the force that hydraulic systems can generate—until now.

The servo-driven valve gate system incorporates a toggle-type mechanism that operates the valve pin position at 90 degrees from the servomotor stroke. A connecting rod between the servomotor and the toggle mechanism (which can be of any length) makes it possible to move the servomotor to what is determined to be an optimal position, including outboard and on the side of the mold. This design enables a much more powerful servomotor to be used to operate the valve gate open/close actuation. A specially designed control system accurately programs the valve pin in eight distinct positions with varying velocity and force in both the opening and closing phases of operation. This provides optimized plastic flow control from each valve gate nozzle into the mold. The science behind the pressure fluctuations and the resulting cosmetic imperfections in molded parts can be determined in the Hagen–Poiseuille equation, which is used to calculate pressure differential in non-Newtonian fluids (plastic):

DP = 8QL n / πr4

(where Q is the flow rate, L is the flow length, n is the viscosity, and r is the radius of the flow channel.)

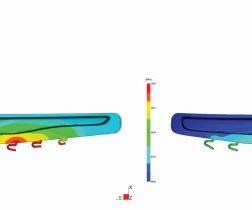

It is especially important to note that the radius dimension in a flow channel has a significant effect on pressure change. In the case of valve gates, this is the orifice area at the end of the nozzle. Even slight change is calculated to the fourth power. Valve gate system designs with only open/close positions produce considerable filling pressure fluctuations due to the large change in nozzle orifice or gate size during operation. The rapid filling velocity and inconsistent decay of the plastic flow entering the cavity produce cosmetic flaws on the part.

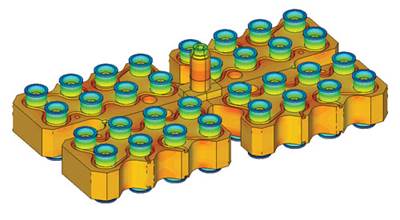

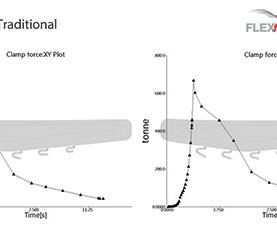

The servo-driven valve gate system precisely varies the effective orifice size in as many as eight conditions. Cavity filling pressures can be controlled more uniformly and without the sudden pressure spikes that occur in conventional systems. Since filling pressure can be controlled to provide a more uniform and predictable rate, component quality is immediately improved. Other benefits realized are less in-mold stress and the tendency for warpage, since fill pressures can be controlled to more uniformly fill the cavity. Part weight and clamp force reductions are also achievable using a servo-driven valve gate system. This is due to no longer requiring the higher pack pressure, or over-packing, used in conventional systems to achieve proper part dimensions in all part areas.

Proving it Out

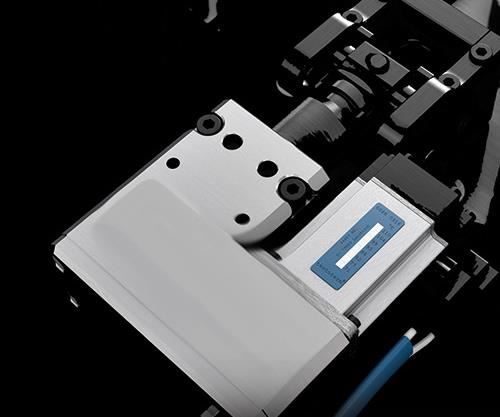

To prove the advantages of this servo-driven valve gate system, a test mold identical in design and construction to a production mold for an automotive roof spoiler was produced. The component, measuring 1,260 by 280 by 120 mm with a wall thickness of 4 mm, was molded from a polypropylene/

ethylene propylene diene monomer (PP/EPDM) compound with 20 percent talc. The mold was equipped with a seven-drop servo-driven valve gate system and seven pressure transducers

located directly opposite the nozzle and at the end fill. A test run using the servo-driven valve gate system produced molded parts that showed improved surface finish over parts produced with conventional systems. A five-percent reduction in part weight was also realized, a direct result of uniform filling pressures and less packing pressure. The required clamp force also was reduced by 20 percent, which provided the potential to downsize the injection molding machine. Reduced injection pressure and a more consistent pressure distribution during the holding phase resulted in a 50-bar (725.19-psi) decrease in the maximum internal cavity pressure of the spoiler mold. This significantly reduces tool deflection, improving mold life.

This type of hot runner system offers eight valve pin positions (opening and closing) for each one of the nozzles with a precision to 0.01 mm, and valve pin stroke can be fine-tuned for speed and acceleration. As many as 16 hot runner nozzles can be individually controlled.

Beyond the improvements achieved by a servo-driven valve gate system in processing, part dimension and cosmetics, these systems also provide operational advantages over conventional, hydraulically operated systems. These advantages include a compact design with reduced mold height, simplified mold installation and maintenance, no water pipes or connections, no oil tubing or connections, and increased contact with the mold (motors can be side-mounted). The potential for material savings and improved mold life also can be directly applied to operational costs.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreFundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreRead Next

Energy Savings in Multi-Cavity Molds

Simplifying maintenance and energy savings in the development of hot runner systems for multi-cavity molds for medical applications.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)