Oerlikon HRSflow Introduces S Series Line with Reduced Nozzle Pitch Size

Hot runner line’s compact design reduces nozzle pitch, plate thickness and offers more rapid color changes for the production of small technical parts.

Photo Credit: Oerlikon HRSflow

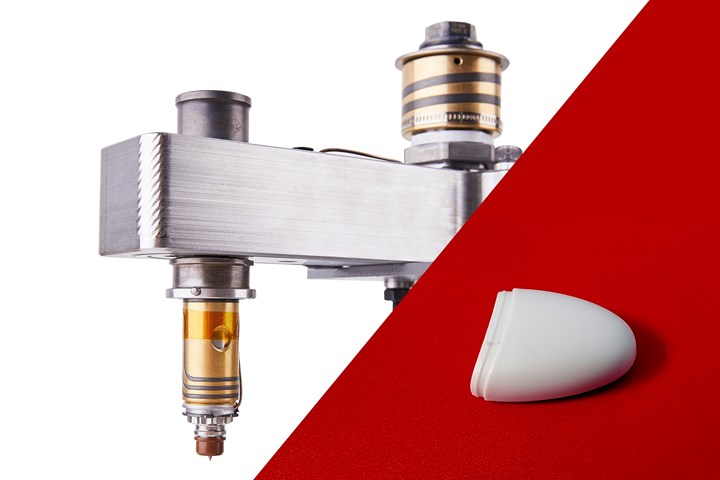

At Amerimold 2021, hot runner manufacturer Oerlikon HRSflow is featuring its S Series hot runner line in a reduced size. Enabling reduced pitch via its compact design, primary applications include the production of small technical parts using engineering plastics. Depending on the application, the S Series hot runner can be equipped with Sa series screwed-in nozzles or Tp and Sp nozzles, which are face-to-face products with different inner bore sizes.

Boasting a compact design, plate thickness reduction for the S Series is now possible. A downsized width further enables a minimum nozzle pitch of 37 mm (1.46”). In the valve gate version, the S Series comes mounted to a compact cylinder with a fixed height of 62 mm or, alternatively, to an adjustable needle position version with a cylinder height of 70 mm. Oerlikon HRSflow says extended in-house laboratory tests have ensured a superior sealing efficiency as well as an optimized thermal profile along the nozzle. In addition, the specially shaped channel geometry allows for more rapid color changes.

Suitable for small-shot weights, multi-cavity tools and thin-wall components, typical applications include consumer goods, technical and electronic components as well as small automotive parts such as exterior emblems, small interior switches, sound system knobs or tiny components in air-conditioning systems.

The company points to the Hydration Reminder as a current S Series application example that meets low part weight, rapid color change and a thickness of only 1 mm. Placed on any bottle or glass, the smart device is able to register every sip.

Exhibitor: Oerlikon HRSflow

Booth 515 (P)

Related Content

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.