Photo Credit, clockwise from top left: Hasco, Kistler, PCS Company and Oerlikon HRSflow

Every shop knows that having the right technology is important for maintaining and increasing efficiency, productivity, reliability and more. MoldMaking Technology’s tech roundups aim to streamline the process of discovering new product or service solutions to keep you in the loop of new developments that may be the perfect fit for your moldmaking operations.

Every month, MMT releases a roundup highlighting different products, processes and services. This month’s roundup has a specific focus on cutting tools and mold components with some miscellaneous highlights from other mold-related categories. (Note: This list only represents the list of digital products shared from June-August. Stay tuned for future roundups for September onward.)

To check out tech from months prior, please browse the “New Tech” section on the MoldMaking Technology website. For more information on a product featured below, click the title link for the respective product.

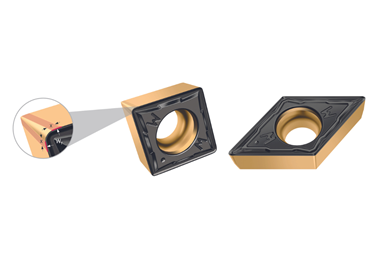

Photo Credit: Walter USA

Positive Wiper Geometries Increase Productivity, Part Quality

With the FW4 and MW4 positive wiper geometries, Walter USA is introducing two indexable insert geometries for longitudinal turning and facing that combine the “wiper effect” and the new highly wear-resistant Walter Tiger-tec Gold Grades. The curved wiper cutting edge is a feature that makes the wiper action universal across various material groups, such as steels, stainless steels, cast irons or even super alloys. The wiper action can be used to reduce machining time by using double the feed rate, while imparting the same surface finish.

Photo Credit: Hasco

Streamlined, Customer-Friendly Website Design Helps Modern Moldmakers

With more than 100,000 products from a single source, Hasco is a full-range supplier for modern designers, moldmakers and injection molders. The company offers its customers worldwide access to a highly modern online shop via an optimized, newly designed website. In a streamlined, user-friendly menu, all information, innovations and services are easily accessible in 16 languages. Molds can be calculated, configured and ordered around the clock with just a few clicks. The mold construction assistant offers innovative possibilities to simplify and accelerate processes.

Photo Credit: Hasco

Mechanical Limit Switch Increases Process Reliability

Hasco introduces mechanical limit switches Z1430 to enable a wide range of possible applications for exact position monitoring of moving components — core pulls or strippler plates, for instance — in injection molding and punching tools, thus also ensuring process reliability and avoiding mold damage. The limit switches, which can be used at mold temperatures of up to 140ºC, and which feature a switching distance Sa of 0.8 mm, can be easily adjusted using the Hasco Z14300 eccentric unit.

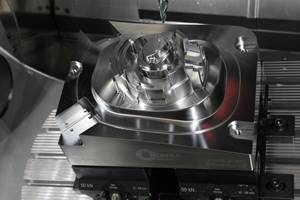

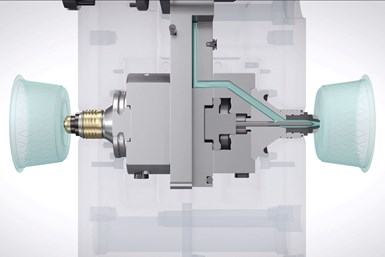

Photo Credit: Oerlikon HRSflow

Compact Stack Mold for Thin-Wall Packaging

Hot runner manufacturer Oerlikon HRSflow has designed a patent-pending compact stack mold for thin-wall packaging applications. Designed to withstand high filling pressures for thin-wall packaging applications, the system can be run on lower tonnage injection molding machines and is equipped with the company’s Xd nozzle series.

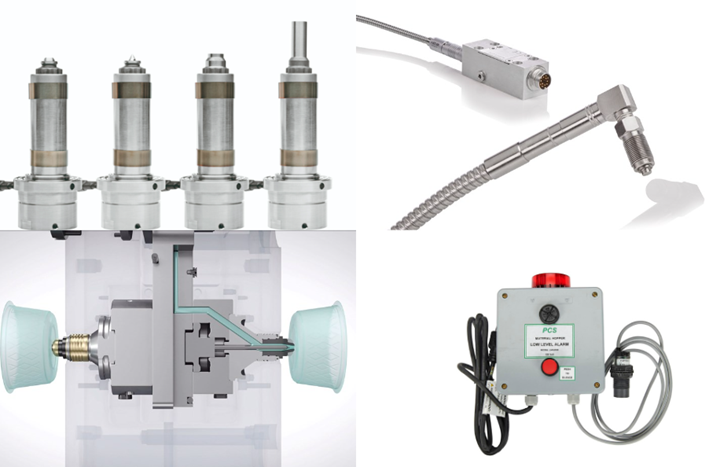

Photo Credit: Kistler

Melt Pressure Sensor Takes Measurements Directly in the Nozzle

Kistler has introduced the Type 4004A piezoresistive melt pressure sensor, feautring a front diameter of 3 mm, which enables it to operate directly in injection nozzles and small extruders. In these spaces, it can measure both pressure and temperature in direct contact with the plastic melt, with potential applications in hot runner systems and additive manufacturing.

Photo Credit: Nikon Metrology

X-Ray CT Systems Meet Diverse Inspection Needs

Nikon Metrology has announced the launch of its next-generation family of X-ray computed tomography (CT) inspection systems called VOXLS (VOlumemetric X-ray Leading Solutions). Designed for diverse inspection needs, the VOXLS family includes the large-volume VOXLS 40 C 450 that is available now and four medium-sized models coming later in 2023.

Related Content

Modular Tooling Systems Enable Versatility in Hole-Drilling Operations

The versatility of replaceable cutting edges offers users the ability to adapt to varied operations.

Read MoreBuilding Molds: Most Popular Reads of 2024

Dive into the most-viewed content for building your mold, including topics such as cutting tools, EDM, hot runners, additive manufacturing, mold materials, machining and mold components.

Read MoreHow to Optimize Mold Finishing

Circle segment technology requires fewer tool paths, improving surface quality and increasing cutting tool life.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreRead Next

MMT Chats: Key Pain Points and Leverage Areas of Advanced Tooling

MoldMaking Technology Editorial Director Christina Fuges chats with Dr. Ahmed Arabi Hassen, R&D Staff Scientist, Oak Ridge National Laboratory, about advanced tooling research and development. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreWhat Do You Really Win as a Leadtime Leader?

MoldMaking Technology has honored many winners since the Leadtime Leader Awards launched in 2003, but what exactly do they win?

Read MoreTech Roundup: Making Sure Your Moldmaking Needs Are Met

This month’s roundup features products, processes and services involved with additive manufacturing, maintenance and repair, mold components and more. To learn more about the products, read on.

Read More

.png;maxWidth=300;quality=90)