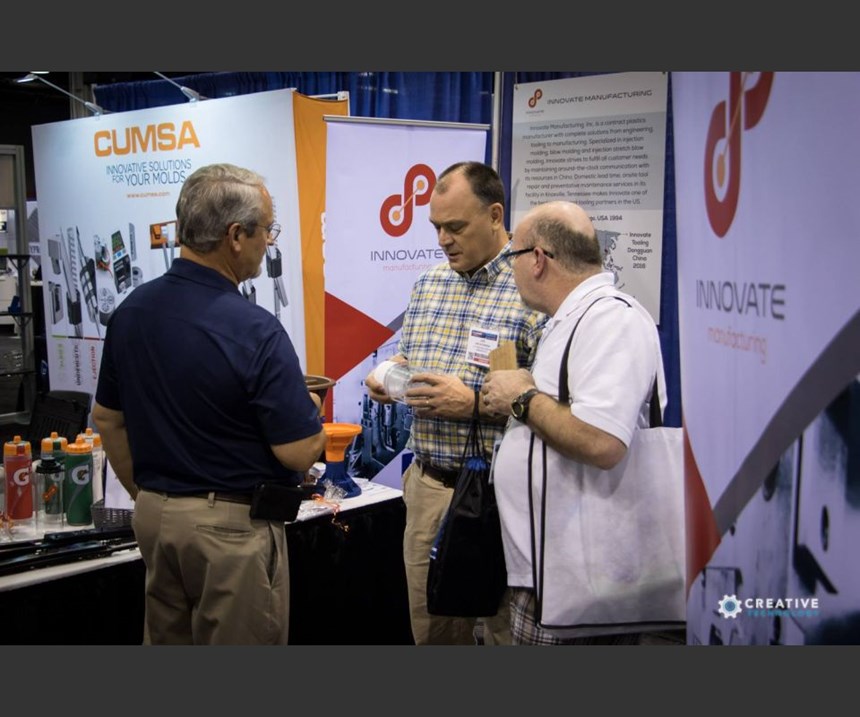

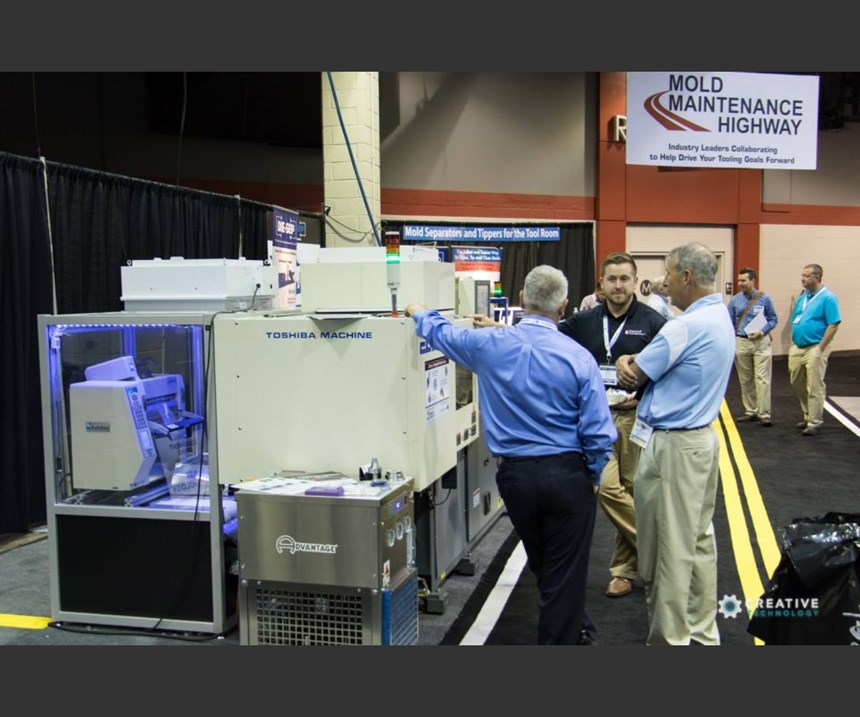

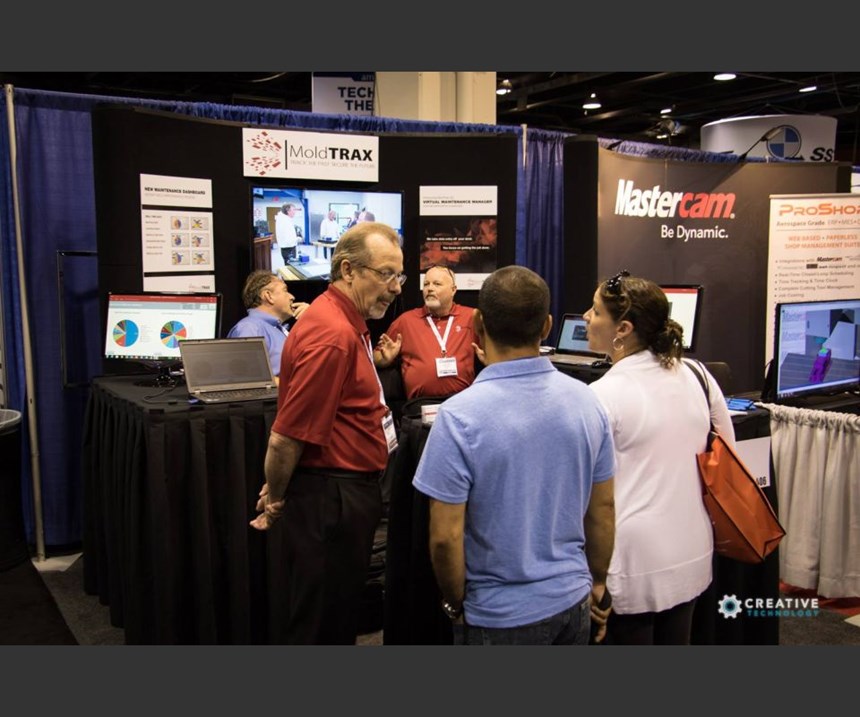

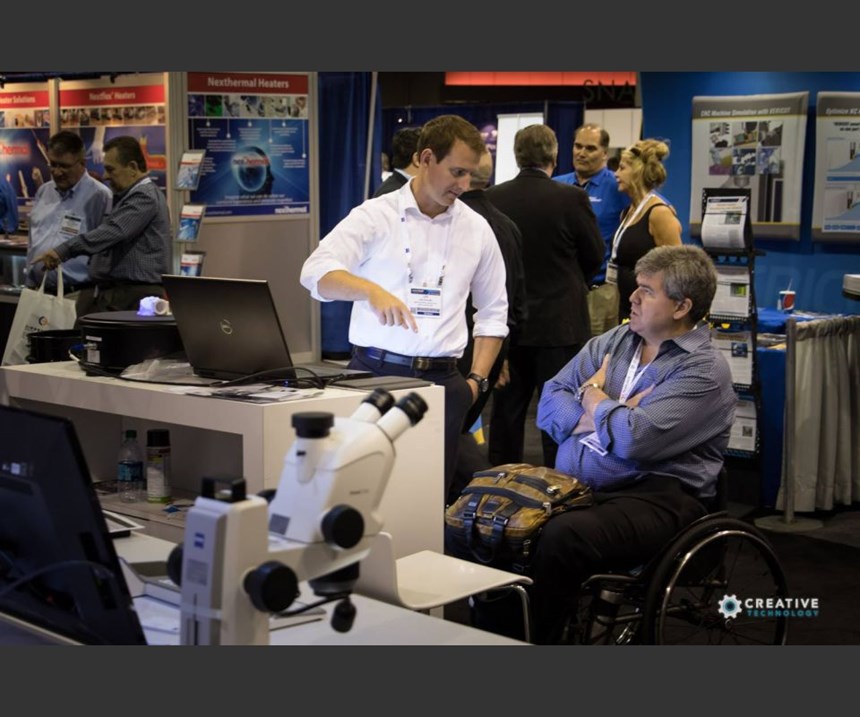

Amerimold 2017: Plastics Exhibitors Promoted Products, Too

Amerimold had it all this year—or should I say it had MORE than ever before. While metalworking tools, materials and systems reigned supreme, the plastics side of the equation was also well represented.

Amerimold had it all this year—or should I say it had MORE than ever before. While metalworking tools, materials and systems reigned supreme, the plastics side of the equation was also well represented.

Today’s Amerimold review puts a spotlight on a few of those exhibitors who offered products and services that attendees just might need to produce quality parts on time. From simulation to molding to mold maintenance and everything in between, there are a number of companies with solutions for plastic-related challenges.

Take a look!

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.