Hot Runner Technologies Advance Quality Surface Requirements in Automotive

Oerlikon HRSflow hot runner systems combine cost-efficient production with a precise process control for a variety of automotive applications.

Hot runner technology enables injection-molded parts with the highest surface quality, as required in particular by the automotive industry. In many applications, systems from Oerlikon HRSflow support cost-efficient, material-saving production with highly precise process control, demonstrated through various project developments with partners.

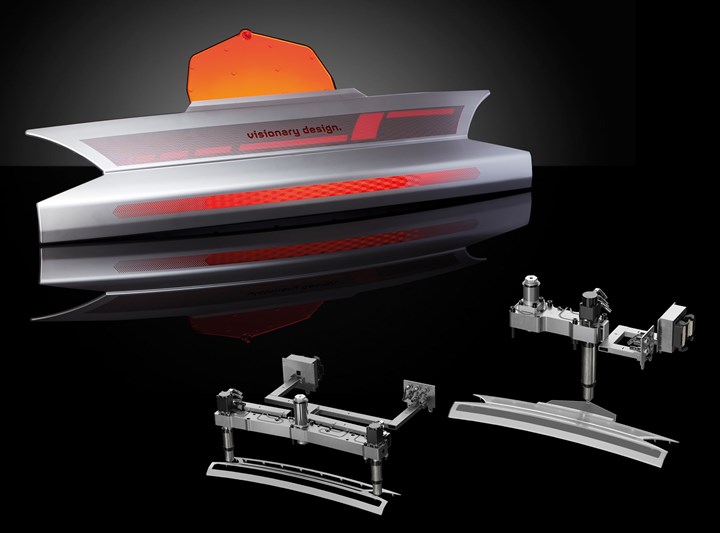

The supporting element of a “smart” car rear panel using 2K technology is a frame made of polycarbonate (PC)/ABS. For example, it can be injection molded using Oerlikon’s hydraulic two-drop hot runner system, overmolded with PMMA or alternatively PC using a single nozzle from the Ga series and the part decorated directly in the mold with a capacitive film. Kurz, Engel and Schöfer also contributed to the success of this innovative project, which required, among other things, extensive rheological calculations due to complex requirements.

Oerlikon has proven the quality of its patent-pending CTC gate insert for the injection molding of an automotive light guide element. The insert is made of steel with optimal mechanical properties and wear resistance. Flash formation can be avoided through good thermal control in the gate area in conjunction with a cylindrical shut-off — both of which are said to help optimize productivity in the manufacture of the light guide element. In general, injection-molded parts that require a wide process window due to difficult conditions such as low shot volumes, long packing times and high holding pressure values are among the typical applications for the CTC.

LED headlight bars made of crystal-clear PC are a proven application of Oerlikon HRSflow’s FLEXflow technology. The system’s servo motors enable synchronized needle movements for precisely controlled flow front progression during sequential injection molding. Sudden pressure drops that occur when additional gates are opened are damped, so that the cavities are filled evenly and residual stresses in the molded part are minimized. There is also a high degree of flexibility during the holding pressure phase, Oerlikon notes, because the needle closing profile (speed and stroke) can be adapted to meet product dimensional requirements.

A joint project between Koller Group, Dietfurt and Oerlikon took it a step further, illustrating hot runner technology potential in the design of future cockpits using a laptop housing demonstrator part.

Related Content

-

Harbour Results, AutoForecast Solutions Release Battery-Electric Vehicle Market Study

The study analyzes the transition from an industry dominated by the internal combustion engine to battery-electric mobility and its impact on the supply chain, which will have ripple effects from automakers to tool and die shops.

-

Specialist Automotive Mold Builder Mentors in Work and Life Skills

Southeastern mold builder PFAFF Molds sets the standard in toolmaking for automotive window and vehicle body sealing systems through knowledge-sharing and automation.

-

Mold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.