Share

Read Next

What is the impact of a hydraulic water leak or scrapped parts to your bottom line? How about the cost savings of consolidating parts into one mold to reduce the total number of molds required for a job? Answers to questions like these require a mold builder to think differently about technology and how the right technology applied correctly can be a true competitive advantage and a way to reduce costs.

Take servo valve gate technology coupled with mold sensors, for example. Let me back up a bit first.

People are familiar with hydraulic and pneumatic cylinders, maybe even servo valve gates (see sidebar below), but do they really understand the difference among these technologies. For example, servo valve gate technology is not simply moving the valve stem open and close with a servo instead of a pneumatic or hydraulic cylinder. This technology gives the user the ability to articulate the pin, opening the door to many other possibilities.

With servos, the pin must no longer be fully closed or opened, which is a common limitation of pneumatic or hydraulic cylinders. With pneumatic or hydraulic cylinders, you have some speed control over that valve stem, but you don't have the ability to articulate it across the cycle.

“That's exactly what servo valve gate technology can do. It can open the valve stems fully, halfway or even vary open and close across the cycle to affect the pressure and flow at each gate independently,” Robert Harvey, director of dales for HRSflow North America, says.

This is a big change in injection molding. In the past, the injection piston defined the process for each gate in the mold, determining the speed and pressure of the plastic flow. With servo valve gate technology, this is no longer true, as it uses the valve stems to meter the plastic at each gate independently.

“This change to the mold controlling the process is a fundamental shift in injection molding. It is a game-changer. It’s the Jetsons versus the Flintstones.”

The original goal of servo valve gate technology according to Harvey was to eliminate hesitation and pressure lines on large-format automotive Class A surfaces. “During traditional sequential valve gating, you open the first gate, and the flow front begins to come out. Then as you open subsequent gates, the flow front hesitates as the pressure dips and cools a bit, creating a hesitation line. With servo valve gate technology, as you open the valve stems, you draw one back closed again, so that the pressure remains constant and the flow doesn't have that hesitation,” Harvey says.

Since tackling this application, developers have discovered many other benefits of servo valve gate technology or independent cavity control.

A Family of Applications

Servo valve gate technology is a powerful tool for effecting flow lines, putting weld lines where you want them and creating a larger processing window to make Class-A surfaces. However, on top of that, independently controlling the flow at each gate opens up opportunities for family molds. Namely, controlling vastly different part weights even with soft-touch materials that tend to flash easily.

For example, if you're not controlling the flow at each gate independently for lighter-weight parts, you’ll push too hard into the cavity and get flash before you fill the other cavities.

Here is another example — an armrest mold with roughly 250 grams of soft-touch material across the top of the armrest. The part also has two posts on the armrest frame that has soft-touch material for dampening the sound when the armrest closes. These posts are 1.5 and 1.4 grams, respectively. The resolution of servo valve gate technology can control the difference between 250 and 1.5, and still have the resolution to control 1.5 versus 1.4.

Now take a door panel family mold with three components with part weights of 10x, 6x and 1x and a very difficult geometry to fill. It is basically a grained door panel assembly. The door panel has a speaker grill, different wall sections and different part weights.

With a traditional system, you set the speed and pressure on the injection piston and all the gates are subject to that process. It is possible to time when to open the valve (it’s digital open or close) based on screw position or time; however all of the gates experience the same pressure as determined by the injection piston. The user cannot push less on the small part and more on the large part to yield greater flow rates on the large part and lower flow rates on the small parts so that they finish filling simultaneously. You can only do that through the timing of the valves, so all of the cavity surfaces are experiencing the same pressure.

The tonnage required to keep that mold closed is the highest pressure requirement part versus the surface area of all the parts together. With servo valve gate technology, the user can open the stems on the small part 25%, 50% for the medium part and 90% for the largest part. Servo valve gate technology can cut tonnage in half by only pushing where you need to push or not applying full pressure to all of the cavities.

Also, through this servo-driven technology, a user can make drastic changes to the way the door panel family mold behaves without even touching the molding machine. This is demonstrated by employing two completely different process cycles.

“On one cycle, you fill all three parts at the same time each with their own process, but it's all occurring at the same time in all three cavities. The very next cycle without touching the molding machine, you fill each cavity one after the other. Cavity by cavity filling, not sequential. Valve gate timing is often called sequential valve gating, but here we are filling each cavity one after the other instead of all at once,” Harvey says.

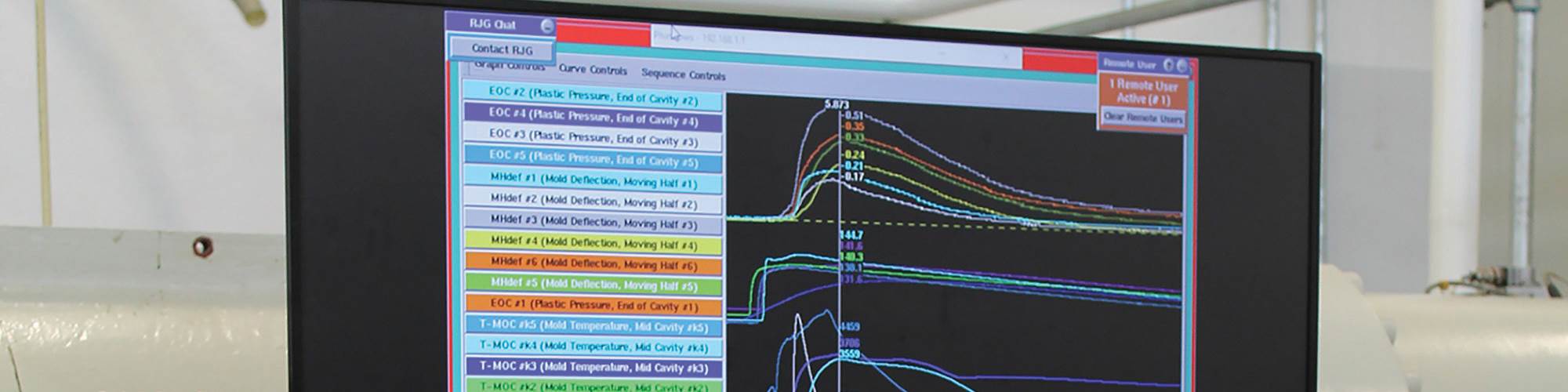

The family mold for interior automotive door parts employs servo-driven valve gate technology combined with feedback sensors.

The Mold is the Machine

The next step was bringing mold temperature, internal cavity pressure and deflection sensors into the picture to remove any process dependence on the screw position.

“With this servo/sensor combination, the molding process is no longer controlled by the molding machine. We tell the machine, ‘Just give us the plastic, and we'll take it from there,’” Harvey says.

Sensors in the mold allow real-time monitoring of deflection, temperature, and pressure during the molding process.

Basically, mold sensors sense events taking place in the mold and fire the valve gates based on that data instead of timing the valve gates off of the screw position. This means that a mold can adapt to the circumstances by seeing what's actually happening in the mold and respond back to the delivery device to effect proper change.

For example, valve gate opening is triggered by temperature sensors in the mold that see when the flow front reaches that point and then behaves according to the profile set in the controller. Valve pin closing is triggered by a sensor that sees an internal cavity pressure of a set amount.

Think about it: if the tool itself can be smart and lock down a process, then shops can rely less on the expertise of a person because you now have a repeatable device. It becomes more science and less art.

“This change to the mold controlling the process is a fundamental shift in injection molding. It is a game-changer. It’s the Jetsons versus the Flintstones,” Harvey says.

The latest advancement in this technology is a servo directly mounted on a manifold, but looking ahead, most innovation will come from software as the value of data and the importance of communicating that data only increases.

Related Content

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More