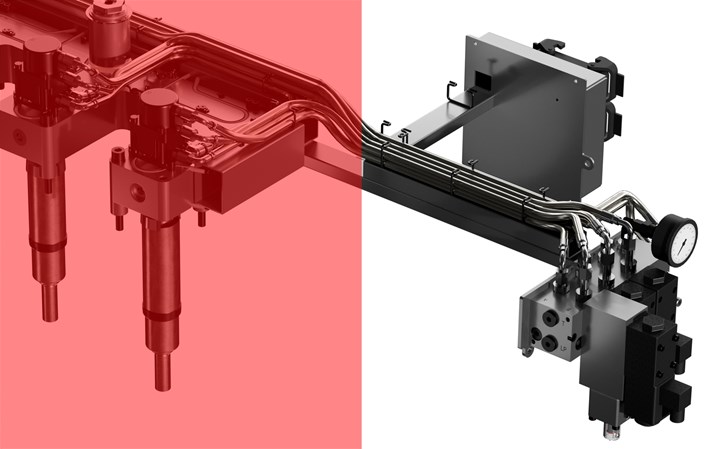

Mechanical Stroke Regulator for Hot Runner Systems

Oerlikon HRSflow’s mechanical stroke regulator (MSR) for hydraulic driven valve gate systems allows for easy pin adjustment even with hydraulic actuation.

Oerlikon HRSflow has developed a mechanical stroke regulator (MSR) for hydraulic driven valve gate systems that reportedly makes it easy to individually preset the opening positions of the pins in hot runner systems. Using a graduate scale adjusting screw, the user can specify the individual oil volume, which the valve gate system then uses to bring the needles into the intended positions. In this way, the pressure drop for each nozzle can be set independently, and the pressure distribution during the packaging phase can be controlled.

Oerlikon HRSflow says it supplies its new MSR ready-to-install on all of the company's existing hydraulic cylinder series equipped with electrovalves. Installation can be limited to individual nozzles of a system to save costs. According to Oerlikon HRS flow, installation only takes around 10 minutes and can be done without dismantling the mold. In addition, modifications to the existing hot runner cutout are not required. Combined with Oerlikon HRSflow's FLEXspeed system, the speed of the pin can also be adjusted.

According to the company, first users unanimously confirm the very good suitability of the MSR for balancing the melt flow in cascade molding and thus avoiding surface defects by simple means. Numerous trials have also demonstrated its successful use in family molds.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Moldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.