MoldTrax LLC

1555 County Road 995

Ashland, OH 44805 US

419-281-0790

steve@moldtrax.com

moldtrax.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

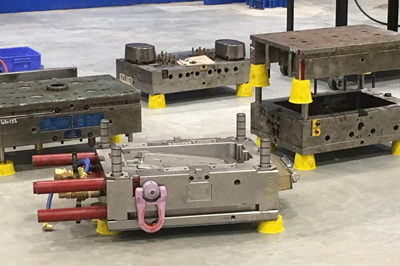

MoldTrax LLC Supplies the Following Products

- Data Management Software

- Mold Maintenance Training

Editorial, News, and Products

-

MMT's Most Popular Maintenance Reads of 2024

Peruse this past year’s top maintenance content, including topics like inspection/measurement, maintenance and repair and surface treatment.

-

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

-

How to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

-

What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

-

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

-

MMT Chats: Award-Winning 2024 Mold Repair Technician of the Year

Scott Phipps of United Tool and Mold (UTM) was honored with the Society of Plastics Engineers (SPE) Mold Technologies Div. (MTD) Mold Repair Technician of the Year award.

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

-

Mold Technologies Division of SPE Announces 2024 Award Recipients at NPE 2024

The Mold Technologies Division of the Society of Plastics Engineers (SPE) honored recipients of four awards at NPE, recognizing excellence in moldmaking and supporting the next generation with a new Apprentice of the Year award. Each winner receives a $1,000 stipend for their training program.

-

SPE Mold Technologies Div. Announces NPE Awards Ceremony Details

The Mold Technologies Division of the Society of Plastics Engineers will announce the recipients of four awards at NPE on May 8 at the MoldMaking Technology Booth.

-

MoldMaking Technology's Most-Viewed March Articles

From mold maintenance to robotics to facing the mold designer shortage — we packed a lot of topics into March you do not want to miss.

-

March 2024 Technology Roundup Highlights

In this most recent roundup, MMT continues to present the breadth of new or proven technologies that target the moldmaking industry, from cutting tools to software to hot runner products, that have been shared this month.

-

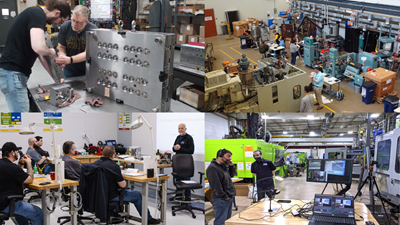

Mold Maintenance Continues to Matter: Enhanced Training Program in a New Facility

I attended a MoldTrax mold maintenance workshop in 2019 and shared my experiences, and despite changes in ownership, the workshop's remarkable value endures, as discussed in a recent Q&A with the current leadership.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

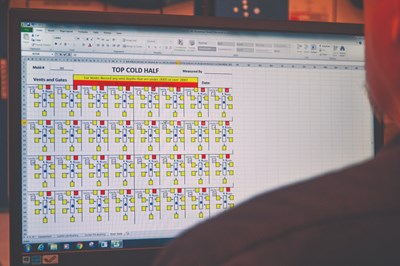

Mold Software Gives Shops a Proactive Approach to Maintenance Tracking

MoldTrax releases feature updates to its MTLinX documentation tracking system to ensure your shop’s molds are running as efficiently and reliably as possible.

-

Time Is Ticking for Nominations for the SPE Mold Technologies Division Awards

The Mold Technologies Division of the Society of Plastics Engineers Inc. is pleased to announce the call for nominations for its four prestigious International Awards, recognizing outstanding contributions to the moldmaking industry. Deadline: February 15!

-

AIM Institute Deepens Mold Maintenance Training Course Learning

Acquisition of specialized equipment used in conjunction with MoldTrax mold maintenance training courses adds to AIM’s virtual and in-person course curriculum for the injection molding industry.

-

SPE Mold Technologies Division Presents Moldmaking Award Winners

At PTXPO, the 2023 Mold Designer of the Year, Mold Maker of the Year and Mold Repair Technician of the Year were awarded to Chuck Heitmeyer, Pat Roussey II and John Demakis Sr., respectively.

-

The State of Maintenance: Where Are You?

New products, equipment and software are beneficial to mold maintenance, but they do not change the fundamental way a repair technician performs the job if the culture remains reactive. Is your toolroom reactive or proactive?

-

2023 SPE MTD Mold Maker, Designer and Repair Technician of the Year Announced!

Mark your calendars for the official announcement of these awards at PTXPO on Wednesday, March 29th at 2:30 PM at the Mold Technologies Division Booth 1614.

-

Breaking Down Hot Runner Maintenance

Improving a manifold’s maintenance plan requires specific skills and knowledge of its functioning areas.

-

Nominations Open for 2023 Mold Maker, Designer and Repair of Person of the Year Awards

SPE Mold Technologies Division is seeking potential nominees for its three annual awards, which will be presented at this year’s PTXPO event. Nomination deadline is Feb. 28.

-

EAB Insight: Maintenance, Management and Money

MMT's Editorial Advisory Board member Rick Seaburg from Medline Industries shares his top MoldMaking Technology articles of all time and how this content has been valuable to his businesses.

-

30 Under 30 Honors Program: Mentoring in the Next-Generation of Moldmaking Professionals

Young professionals are vital to the moldmaking industry, and it is important to acknowledge those making strides in shaping the industry's future. MoldMaking Technology recognizes the industry's young talent through its 30 Under 30 Honors Program.

-

New SPE Award Recognizes Mold Repair/Maintenance Technician Personnel

The Mold Repair/Maintenance Technician of the Year 2023 seeks nominations to highlight “the crime scene investigators” of the moldmaking industry. Submit your nominees now.

-

MoldMaking Technology's Top-Viewed Content 2021: Features

These popular articles from 2021 highlight a range of topics, from the 2021 Leadtime Leader, tips on supplying cooling to additive tooling and best practices to improve efficiency. Revisit some of your favorites, or take a look at what you’ve missed.

-

Here Are Your Top 10 Most-Read Features of 2021

A list of the most-viewed features in MoldMaking Technology from January to November 2021.

-

MoldTrax MTWEB Efficiently Tracks Performance, Repair and Maintenance

Documentation tracking system for a proactive maintenance 4.0 culture to make an appearance at Amerimold 2021.

-

Mold Maintenance Software Company Delivers Consulting, Certification Courses

MoldTrax offer moldmakers year-long ToolingDocs certification training courses and a maintenance capabilities assessment (MCA).

-

Step 1 of Your Maintenance 4.0 Documentation Strategy

This free on-demand workshop reviews 1 of the 5 critical components to continuous improvement—mold maintenance documentation—and shares a “test” to score your toolroom on its mold maintenance documentation strategy.

-

Free Webinar Today: Is Your Mold Maintenance Documentation Reactive, Basic, Average, Best Practice or World Class?

Find out in this free webinar that will not only review the changing mold maintenance landscape, explain the importance of a 4.0 culture, break down the 8 factors of mold performance, provide examples of “futile” work order systems, instruct how to create standard terms, it will also score your toolroom’s mold maintenance documentation strategies.

-

Do You Know Your Toolroom's Mold Maintenance Documentation Score?

Does your toolroom have a Reactive, Basic, Average, Best Practice or World Class culture when it comes to collecting and using Industry 4.0-type mold maintenance documentation? Steve Johnson and Glenn Keith of MoldTrax will help you answer that question during this FREE webinar on March 30 at 2PM EST.

-

Free Webinar: Score Your Shop's Mold Maintenance Documentation

Mark your calendars to attend a free webinar on March 30 at 2PM EST that will help you score your shop’s Industry 4.0 mold maintenance documentation practices.

-

WEBINAR: How Does Your Toolroom Stack Up?

Free webinar on March 30 at 2PM EST offers live scorecard activity that will reveal your toolroom’s 4.0 Mold Maintenance Documentation Capabilities.

-

Alba Enterprises Relocated NA Headquarters, Opens New Facility

New production, service and training facility in Loveland, Colorado, ramps up 3D modeling and mold sampling capabilities in order to deliver comprehensive, multidisciplinary guidance solving application needs.

-

How to Use Flushing to Clean Cooling Passages and Heat Exchangers

Six key questions to ask before investing in a flushing system.

-

2020 Sourcing & Technology Guide: Mold Maintenance, Repair & Surface Treatment

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services with 11 sections, including Mold Maintenance, Repair and Surface Treatment.

-

2020 Sourcing & Technology Guide: Software

MoldMaking Technology’s annual Technology Review and Sourcing Guide is a comprehensive guide for researching today’s technology, equipment, products and services with 11 sections, including Software.

-

Amerimold Connects Kicks off with Tool Shop Live Demo of a High-Level Hot Runner Mold PM

The reason we are kicking off the event with this topic is because at the heart of making things is the mold, and since the mold impacts every link in the supply chain—OEM/brand owner toolrooms, molding facilities and mold building shops—mold maintenance is vital. So we felt it’s only appropriate to kick off this event with a “virtual” hands-on look at a proper hot runner preventative maintenance routine.

-

Throwback Thursday: Hot Runner Supplement 2017

This Throwback Thursday is all hot runner focused, with features from our special supplement issue geared toward helping readers with common challenges.

-

VIDEO: Elements of a New Age Repair Shop

Just as important as creating a solid maintenance plan for molds, is the shop in which the repair takes place. In this Toolroom Live Demo, Steve Johnson of MoldTrax presents an overview of a successful toolroom setup that includes a variety of essential bench and cleaning equipment on the market today.

-

Getting Hot and Heavy during a Little Hot Runner Training

If a mold is the heart of a molding system, then the hot runner system is the heart of a hot runner mold, and I recently learned that there is a lot to know when it comes to designing and maintaining these systems to ensure optimal mold and part quality and performance.

-

Noteworthy News: Building Blocks

Moldmaking companies are the building blocks to this community, so catch up on recent news releases to see which ones are building onto their businesses through expansions, additions and new openings!

-

MoldTrax Hot Runner Extravaganza Delivers on Expertise and Education

The “Who’s Who” in processing and hot runner technologies turned out to educate attendees with well-honed wisdom and experience.

-

Amerimold Action 2019

Amerimold celebrated 20 years in Rosemont, Illinois, and offered attendees a wide variety of products, programs and pomp.

-

Understanding Manifold Thermal Expansion

Molders, mold builders and repair technicians must fully understand thermal expansion to ensure they don’t damage critical seals during manifold repairs or routine cleanings.

-

Mold Maintenance Refresher

As I hit the road to attend a hot runner maintenance workshop this week, I’m reminded of my last maintenance-related education session. So, I thought I’d share some images and tips as a little refresher on what I learned.

-

PODCAST: Educators in Mold Maintenance

The key to successfully educating mold builders and molders about mold maintenance is to listen twice as much as you talk for the improvement in finding problems and creating solutions.

-

PODCAST: Mold Maintenance-No Longer an Afterthought

After attending an intensive three-day mold maintenance workshop earlier this year, it was a real pleasure to sit down with two of the workshop’s mold maintenance educators to learn more about what makes them tick both personally and professionally.

-

Amerimold 2019: New Programming Wrap-Up

There is always something new at Amerimold, and this year was no exception.

-

Amerimold 2019 Update: Tool Shop Live!

Mold maintenance and repair is a team effort. It involves communication and collaboration among suppliers, mold manufacturers and customers to ensure that the appropriate people, technologies and processes are put in place to keep a mold running. That is the motivation behind Tool Shop Live! at Amerimold next week.

-

Amerimold 2019: Attendees Will Benefit from Educational In-Booth Demos

Amerimold presents in-booth demonstrations of 3D printing, machining, hot runners, mold maintenance, molding, and more.

-

Amerimold 2019 Update: What You Should Know about Improving Your Third-Party Mold Maintenance Culture

Husqvarna and MoldTrax have teamed up to review a PM action plan and the barriers to systemize and change the mold maintenance and repair culture across multiple facilities.

-

Maintaining Mold Components

Toolroom technicians must include frame plates, frame components, and cavity tooling when developing a mold maintenance plan.

-

How Will Industry 4.0 Impact Mold Maintenance?

Many toolrooms want to replace manual entries with electronic data when creating maintenance work orders and providing past historical issues, corrective actions and the effectiveness level of resolutions, but technicians require more information than electronic signals can provide to prove a return on investment of their time.

-

Complex Molds Require Advanced Maintenance Strategies

As molds become more complex in design and function, the demand for advanced training and equipment for mold maintenance increases.

-

How to Set Accurate Manifold Preventive-Maintenance Frequencies, Part 3

The only thing that can mess up a solid PM plan for a manifold is a poorly designed system, and there are a variety of manifold designs and complexity levels. Many design features are the root cause of postponing a manifold PM until it breaks down.

-

Scenes from Amerimold 2018 in Novi, Michigan

From technology demos and tech talks to awards and arcade games, Amerimold had much to offer industry this year.

-

How to Set Accurate Manifold Preventive-Maintenance Frequencies, Part 2

The key to developing accurate and timely PM work instructions is understanding the impact of environmental factors on manifold performance.

-

How to Set Accurate Manifold Preventive Maintenance Frequencies

Clearly setting accurate manifold preventive maintenance frequencies requires reliable comparative data on how a hot runner system performs over time.

-

Connecting Mold Builders and Buyers at Amerimold 2018

Mold buyers and builders experience many of the same challenges for which they are each seeking solutions and that is where Amerimold comes into play.

-

Amerimold: Solving Customer Problems

Two back-to-back presentations at Amerimold next month address mold performance issues with a focus on mold maintenance and scientific molding strategies.

-

Maintenance Matters: Look How Far Mold Repair Has Come

To understand how repair shops have changed over 20 years, look at a company’s ability to break down, measure and apply specific data in the five factors of total mold control.

-

Throwback Thursday: Hot Manifold Repair: What’s so Tough about it?

Today’s TBT discusses how maintaining a typical hot runner system takes mold maintenance skills to the next level.

-

Technology Tuesday: Hot-Runner Maintenance

Cruise through this week’s Technology Tuesday slideshow to see articles and products on hot-runner maintenance.

-

Collaborate to Educate on Plastics Technologies

Moldmakers, industry consultants and technology suppliers collaborate to educate on plastics technologies.

-

Maintenance Matters: The Physical Side of Data Entry

A mobile documentation station promotes on-the-fly data entry and usage for mold repair technicians, ingraining documentation into the daily maintenance process.

-

Technology Tuesday: Mold Maintenance and Repair Products

Cruise through this week’s Technology Tuesday slideshow to see the latest products in mold maintenance and repair.

-

Moldmakers Choose Different Pathways to Workforce Development

Mold manufacturing companies share their strategies, the challenges they face and their commitment to training the next generation of makers.

-

Processing and Mold Repair Teams Collaborate to Solve Problems

Processing and mold repair technicians must work together as a team to solve mold problems quickly and correctly.

-

Processing and Tooling Come Together

Mold designers, tooling and process engineers, managers, supervisors, repair technicians and molders can come together to learn how to efficiently produce quality parts on time during this inaugural Mold Performance Technology conference.

-

Technology Tuesday: Hot Runners

In honor of this year’s supplement issue, this week’s Technology Tuesday blog features recent hot runner products.

-

Special Coverage: Hot Runner Technology

MoldMaking Technology provides special coverage of hot runner technology as a supplement to the October 2017 magazine. Read the entire supplement here, or check out the supplement page to read each article individually.

-

Maintenance Matters: The Right Personalities are Key to Reducing Workplace Breakdowns

Building an efficient, successful team with the right attributes reduces the incidents of mold breakdowns.

-

Maintenance Matters: Cultivating Craftsmanship

Toolroom managers need to help repair technicians become skilled mold troubleshooters and craftsmen rather than tooling replacers and cleaners.

-

Throwback Thursday: Codes of Conduct

Culture is a topic that comes up a lot in conversations among mold builders, so I felt this throwback to an article on the communication/teamwork chasm was worth a second look.

-

Amerimold 2017: Plastics Exhibitors Promoted Products, Too

Amerimold had it all this year—or should I say it had MORE than ever before. While metalworking tools, materials and systems reigned supreme, the plastics side of the equation was also well represented.

-

Maintenance Matters: Got Flash? Shim it!

In some cases, shimming is the most cost-effective, short-term method for adding a bit of steel right where its needed to get through a critical production run.

-

Metrics for Assessing Maintenance Skills

Since the job description, qualifications, direction and goals may not be so clear, assessing a repair technician’s value can be confusing. Objective, tangible metrics are a must.

-

Motivating Skilled Toolroom Craftsmen

Steve Johnson, president of MoldTrax, has a lot to say about mold maintenance. So much so, that we could not fit it all into his February "Maintenance Matters" column. Here are some extra pointers that didn't make the cut, but are just as important.

-

Throwback Thursday: The Black Art

With my mold maintenance champion returning to the pages of MMT next month with his new "Maintenance Matters" series, I thought I'd revisit the start of his original series with us back in 2004.

-

Do Scheduled PMs Really Work?

True preventive maintenance lies in accurately monitoring and counting issues and corrective actions over time.

-

Setting Up Shop for Proper Mold Maintenance

It can’t be said enough how important proper, systemized mold maintenance is to the overall productivity of molds.

-

Getting Started with Hot Runner Maintenance

Developing basic cleaning and repair skills among in-house technicians should be the goal of every shop that runs hot runner systems.

-

Common Sense Innovation and Moldmaker Collaboration

As I walked the aisles of NPE last month, taking in all the plastics-related technologies and solutions on display, two obvious trends emerged: logical innovation and moldmaker collaboration.

-

Case Study: Mold Maintenance & Repair

Certified Mold Maintenance System Completes Service Offerings

-

To Rail or Not to Rail

One of the most interesting parts of performing a maintenance capability assessment (MCA) in mold plants around the globe is observing the different styles practiced when repair technicians work on molds. When talking to repair techs about why they like a particular method or tool it is easy to see why they would think there is only one way to do things. It’s simply how they were taught by the older, tenured repair technicians.

-

Detecting Water Flow Restrictions

A look at how taking the time and data to analyze a mold problem will help you repair it right—and permanently—the first time.

-

Building a Better Mold

A look at mold performance and maintenance issues through a few simple reports in the right sequence will allow you to drill down into what the issues are really costing you.

-

Maintenance Manuals That Work

Organized maintenance manuals can offer an advantage that electronic data does not.

-

Maintenance Data for Processing Technicians

Data that processors need and what they should collect.

-

Part Two of a Two-Part Series Optimizing Mold Performance And Maintenance Efficiency

The last three steps of a six-step process for strategizing for improvement in shop operations when it comes to how we maintain molds.

-

A Tribute to Tools and Those Who Use Them

Tools and the boxes that contain them tell a lot about the moldmaker and his/her talents.

-

Cleaning a Flashed Hot Manifold, Part Three

Cleaning nozzles and manifolds, electrical boxes, assembly and final check.

-

Cleaning a Flashed Hot Manifold, Part One

A look at in-house and outsourced cleaning.

-

Part Three of a Three-Part Series Detecting, Repairing and Preventing Water Leaks

Clear cut methods that prove effective on troublesome installations.

-

Evaluating Mold Repair Skills

The keys to proper mold repair on-the-job training are an organized, systematic shop atmosphere, and an understanding of mold repair skills requirements and the mold characteristics that challenge those requirements.

-

Setting Up Shop, Part IV

Creating a clean room.

-

The Final Check

A simple mistake can be catastrophic for both sales and the mold, making a final checklist a must.

-

Cleaning Molds: Part III

Ultrasonic immersion cleaning is a non-abrasive, user-friendly method that has the greatest impact on reducing cleaning time, improving mold cleaning consistency and reducing tooling damage.

-

Cleaning Molds: Part I

Cleaning a mold is a critical part of the repair process, but many myths must be dispelled.

-

Troubleshooting Defects: Part II

Repair technicians should be aware that careful handling of tooling, attention to detail and documentation keeps manifolds functioning properly and prevents costly mistakes.

-

Across the Bench: Troubleshooting Defects: Part I

Using analytical skills based on historical mold performance and maintenance requirements, combined with mold and part defect data determines probable causes and corrective actions.

-

Across the Bench - The Plan Comes Together

The repair sheet is critical to the success of any mold repair plan.

-

Across the Bench - Creating a Repair Plan

The last shot is the most important key to insuring accurate mold repair.

-

Across the Bench: Let the Run Begin

Setup checklists, verifications and injection mold layout sheets are critical factors in the beginning of the mold process.

-

Across the Bench: One-Man Solution

A tool specifically designed to make tooling removal a quick, safe, one-person job helps moldmakers get jobs done quickly and efficiently.