Throwback Thursday: The Black Art

With my mold maintenance champion returning to the pages of MMT next month with his new "Maintenance Matters" series, I thought I'd revisit the start of his original series with us back in 2004.

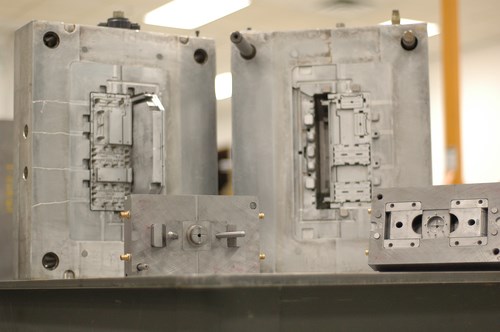

Steve's first article included a sidebar on The Blark Art of mold maintenance:

Mold maintenance is considered a black art because there are very few formal training programs for repair technicians or management to attend in which to study standard practices and procedures. There is no mold maintenance bible available to consult when a mold oozes plastic from the top of the electrical box during a critical production run. Proactive, predictive and preventative normally surround anything mechanical in the industry and until mold maintenance is understood, knowing how to make them work will remain a mystery.

The range of perceived qualifications in the industry is incredible. Many employers aren't sure what background prospective repair technicians should have, while employees are getting bogged down and burned out. Poorly equipped shops fill up with half-assembled molds waiting on tooling that should have been in stock, molds victimized by unnecessary and costly mistakes or molds that are run to death. Backup molds are never available. It's easy to understand why freelancing repairs and firefighting hot problems are accepted solutions for many companies.

Quality craftsmanship can no longer be an elusive skill companies only hopetheir technicians have; it must be a requirement. Maintenance technicians must be held accountable. This can be accomplished by gradually shifting to a systemized approach to understand and correct mold and product defects. A shop's operation is in management's hands. Supervisors must be able to measure mold performance and repair criteria. As the old saying goes, 'You cannot improve on something that you cannot measure.'

Take a look at his entire first article here.

Related Content

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

-

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

-

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.