Do Scheduled PMs Really Work?

True preventive maintenance lies in accurately monitoring and counting issues and corrective actions over time.

It seems like such a simple question with such an obvious answer, however, the wide range of opinions expressed during our mold maintenance training courses might surprise you. Common mechanical sense says of course preventive maintenance (PM) works. Why wouldn’t it? So we additionally ask, What does it do for you? Does it eliminate product defects or mold breakdowns? Does it reduce maintenance and labor costs? Does it keep the OEM happy? The actual benefits of PM are not so clear.

During our maintenance strategy discussions, we ask which attendees have a structured, adhered-to PM program in place. Typically, a few hands go up. Then we ask how many have a PM schedule that has been validated over time to be effective based on mold- and part-defect frequencies, corrective-action costs and cycles, or some form of odometer. Typically, no hands go up. Some shops have such schedules but agree that they have not been proven to be much more effective than a decent cleaning, and even that is a struggle to get accomplished on time. Still other shops run the mold until it breaks down or until the order is complete, and then perform PM.

For most, scheduled PM occurs when a mold is stopped after a certain number of cycles or parts have been run, and then it is cleaned and greased. Seldom does anyone bother to scour past workorders filed away in cabinets looking for repeated product or mold issues that cause ongoing defects and unscheduled mold stops. Some shops also don’t take time to review the last shot, or take measurements of critical seals or tooling fits to proactively ward off problems. The depth or level of the PM is typically based on what someone thinks the mold needs. It is a subjective decision rather than one based on historical maintenance data.

Because there are so many things that could stop production and/or cause product defects at any time, shops need to understand that regular cleanings won’t achieve every molder’s

goal of efficiently producing quality parts on time. The bottom line is that molders and molds have problems that will not all be solved through scheduled cleanings. Molds require more attention.

So if regular cleanings aren’t the answer then what is? The critical ingredient to real improvement lies in the ability to accurately monitor and count issues and corrective actions over time, with “time” being mold cycle counts or parts produced. Mold performance does not rely solely on molds being cleaned more often, but on the monitoring of defects and mold issues to create a viable list of targets that users can focus on when molds are taken out for PM. It is imperative for continuous improvement that a shop can determine with relative ease and accuracy its top issues, as there are just too many variables to monitor to be continuously effective. The maintenance strategy must aggressively go after production-stopping issues.

Where to Start

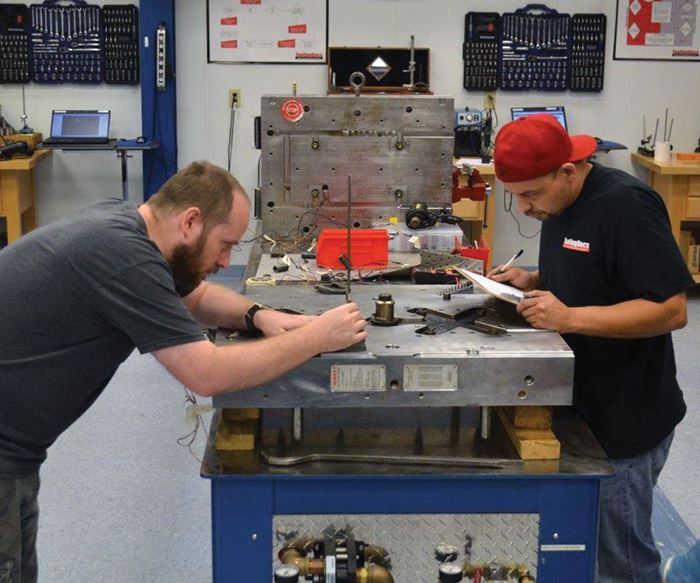

Many times shops want to improve their root-cause analysis when they should first make sure they are chasing the things that are worthy of their time and effort. When a mold lands on a bench for PM (or for any reason) repair technicians should use that time to utilize and grow the knowledge base about that mold. Part of a reliability-centered maintenance strategy (the process used to determine the most effective maintenance approach or to ensure that systems continue to do what their users require) is identifying issues instead of blindly performing PM without being up to speed on historical problems.

Start by developing a list of reasons for mold stops. In a good maintenance system, this will consist of about 30 reasons categorized as “scheduled” or “unscheduled.” Shops using standard workorder forms likely have already discovered that the typical work-order heading is usually a typed-in statement, as opposed to a standard term. Part of the discipline of documentation is requiring those in charge of creating mold PM or mold workorders to use standard terms that are sortable and measureable. We just don’t use data like we should. For example, when a repair technician types in “fixed it,” “done” or “completed” for a corrective-action resolution, this information can be viewed on a global scale, but what does it actually accomplish? You have maintenance confusion on a global scale with time, money and resources wasted on repetitive issues and other defects that slip through the cracks.

The flip side of “fixed it” are long, overdetailed ramblings of repair technicians trying to do the best job they can, and give subsequent technicians a complete picture of what maintenance was needed and performed on the mold. The problem here often is the lack of clear technical writing within these long stories. They typically are written in non-standard language, which takes longer to decipher, and that next technician doesn’t get all the data he needs.

Next comes counting mouse clicks, a technique used to measure the “cumbersome” level of a maintenance system. For example, the more clicks required before the user is finally able to access the information needed will dictate his or her level of affection for any maintenance program. Also not popular are database crashes and slow-moving systems. Add all these circumstances up, and you can guarantee a fixed-it-type entry on the maintenance log. The more clicks necessary, the less the system will be used.

We are not trying to discount all the great features that have been added to electronic maintenance systems over the years, but as long as shops are collecting critical maintenance core data with free-form text-field brain dumps instead of using standardized shop language, they will continue to struggle to develop real, measurable metrics and be truly proactive.

That is the answer: to develop and use standard terms. Make a list of these terms and hang them up for all to get familiar with and use on a daily basis. It will take a meeting or two among quality staff, the molding manager and the toolroom manager to create terms for the core areas, but the time spent on this will be recouped many times over with more accurate data and the ability to quickly sort and count entries.

This also will require data discipline and employee accountability, but it will enable a shop to create defect targets and goals for all molds and take advantage of the accumulative knowledge concerning how its molds run, and what maintenance is required to keep them running reliably and efficiently.

The short, but critical list of standard terms includes:

• Mold stops (scheduled and unscheduled)

• Defect categories and terms (electrical, mechanical, product, process, maintenance and so on)

• Tooling terms (horn pins, leader pins, guide bushings, interlocks and son on)

• Corrective action terms (replace, clean, rework, fabricate, polish and so on).

The tooling and labor costs should be associated with every defect, so a shop knows which defects are costing the most money in corrective-action repairs. Understanding which issues are stopping it from efficiently producing quality parts on time can help a shop to develop a list of ongoing targets to post and assign to the repair technicians, as opposed to asking them to fight fires every day. This is what true proactive maintenance is all about. Only when the shop has a better handle on what is stopping/slowing production and the real costs of maintenance, and when it can relate these to known cycle counts, can it create validated and effective PM work instructions for its molds.

If all you do is periodically clean and conduct PM on molds, then you are leaving all defects, unscheduled stops, high tooling costs, high labor costs, quality issues and general stress to Mr. Murphy, the alignment of the stars, phases of the moon, signs of the Zodiac—in other words, to chance. Not one of those will work as effectively as maintenance tracking with accurate data.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreRead Next

Getting Started with Hot Runner Maintenance

Developing basic cleaning and repair skills among in-house technicians should be the goal of every shop that runs hot runner systems.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More