Motivating Skilled Toolroom Craftsmen

Steve Johnson, president of MoldTrax, has a lot to say about mold maintenance. So much so, that we could not fit it all into his February "Maintenance Matters" column. Here are some extra pointers that didn't make the cut, but are just as important.

Steve Johnson is president of MoldTrax Maintenance Solutions, which provides specialized course work, hands-on bench training, maintenance software, maintenance products, toolroom design and maintenance efficiency auditing. I have been working with Steve since we started MMT back in 1997. He always has a lot to say about mold maintenance, but more importantly he also has a ton of passion for the subject.

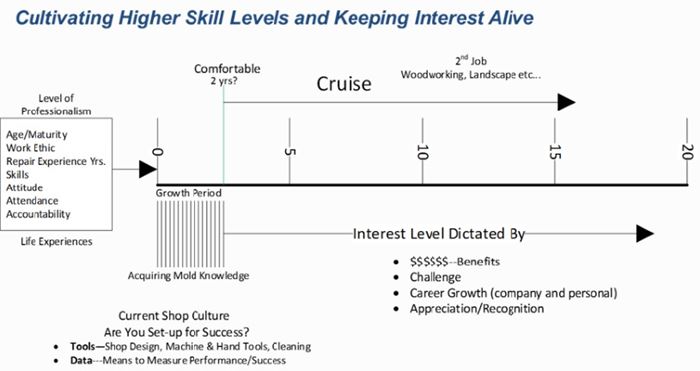

Steve's focus in his initial article for his 2017 Maintenance Matters column was on the toolroom manager's role in employee motivation when it comes to mold maintenance and repair. Basically, he believes toolroom managers and supervisors set the pace of the shop and overall efficiency of the toolroom, so knowing how to train and motivate skilled craftsmen is key.

In a nutshell, he says a majority of repair technicians are either cruising through work or trying to make things worse, while the molds they repair are being run and looked after by folks who really don’t give a hoot about anything job related. Not a good situation.

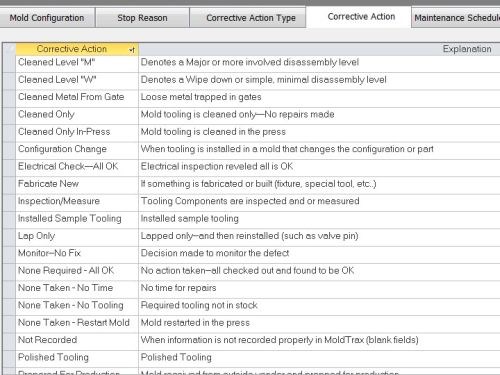

Although his column explains the dilemna in detail and provides some solid strategies for proper motivation, we couldn't give him all the room he needed. So, I thought I’d share a few extra tidbits on employee motivation progression, standard terms and proper toolroom setup that didn't make the print issue in a slideshow.

Related Content

-

5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.