Amerimold 2019 Update: Tool Shop Live!

Mold maintenance and repair is a team effort. It involves communication and collaboration among suppliers, mold manufacturers and customers to ensure that the appropriate people, technologies and processes are put in place to keep a mold running. That is the motivation behind Tool Shop Live! at Amerimold next week.

Mold maintenance and repair is a team effort. It involves communication and collaboration among suppliers, mold manufacturers and customers to ensure that the appropriate people, technologies and processes are put in place to keep a mold running. It is critical that this aspect of the mold manufacturing process not be undervalued, and oftentimes it is. Many shops continue to express their frustration with the lack of the right people, technologies and processes to properly maintain and repair molds.

That is the motivation behind Tool Shop Live! at Amerimold next week.

Just as important as creating a solid maintenance plan for molds, is the shop in which the repair takes place. Tool Shop Live! consists of the following technology and service suppliers, each offering solutions for every shop’s mold maintenance and repair challenges and needs.

- MoldTrax

- ToolingDocs/Progressive Components

- Fast Heat

- Polymer Cleaning Tech.

- Cold Jet

- Dailey Supply

- Die Sep

- Gesswein

- Blue Wave Ultrasonics

Throughout Amerimold’s two days, this team of exhibitors will be offering presentations and demos. However, specifically on June 12th at 3pm, Steve Johnson of MoldTrax will present an overview of a successful toolroom setup that includes a variety of essential bench and cleaning equipment on the market today followed by some Q&A about proper shop layout. Each of the nine Toolroom Live Technology Partners will then take the floor to demonstrate their specific products and systems, and to answer any questions. Attendees can enjoy a cold beer while watching these equipment demonstrations.

Specific topics the presentations and demonstrations will address include:

- Typical toolroom sizes and layout suggestions to accommodate a variety of mold sizes, mold pull pace and workflow considerations

- Bench types, spacing and placement considerations

- Bench cell setups and the necessary utilities to include at the bench

- Overhead hoist considerations (bridge, mono-rail, jib, and A-Frames) and the benefits and limitations of each

- Cleaning machines options (ultrasonic, dry ice and media blasters) and placement recommendations including the strengths of each system

- Proper lighting requirements and available options

Register for Amerimold Today!

Related Content

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

-

How to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

-

What is Scientific Maintenance? Part 2

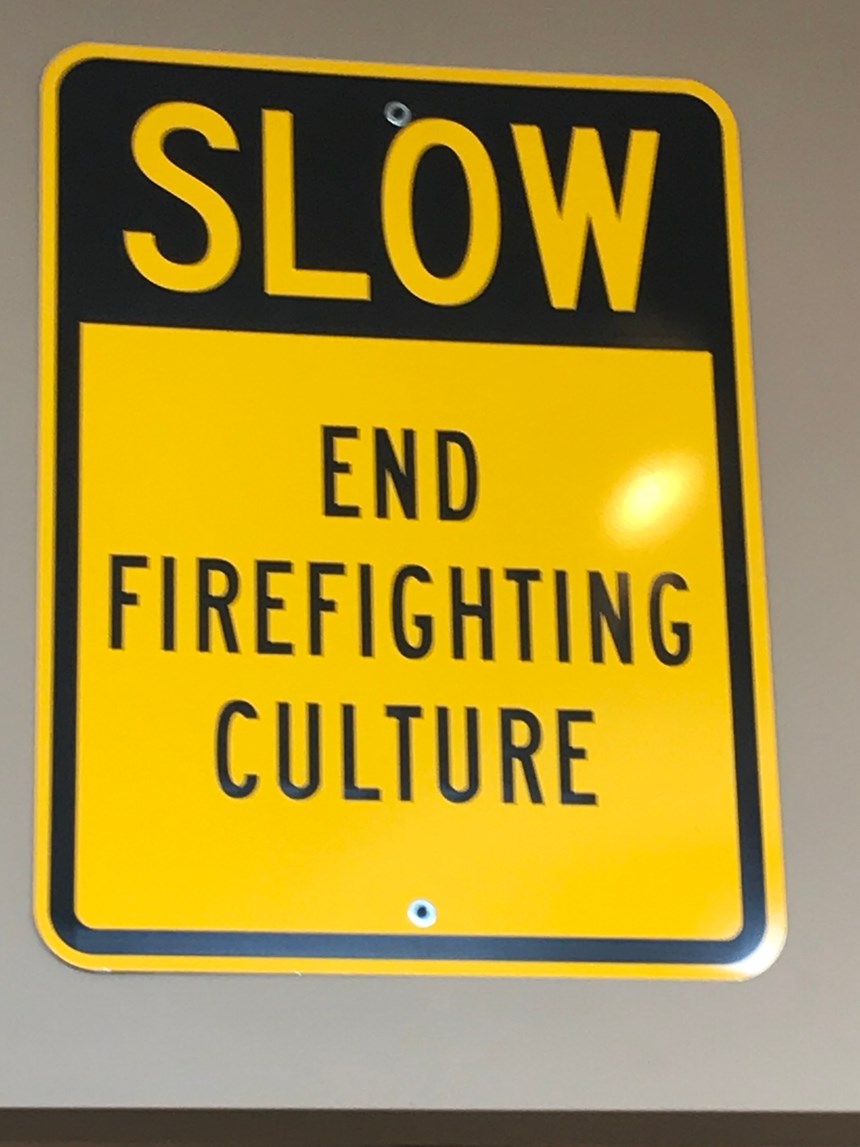

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

.jpg;maxWidth=300;quality=90)