Mold maintenance has moved up the priority list of many toolrooms across the mold manufacturing supply chain this past year, so in addition to MoldMaking Technology’s three-part Scientific Maintenance article series with mold maintenance expert Steve Johnson of Mold Trax, we thought a webinar was in order to dig a little deeper. Photo Credit: Mold Trax.

Steve Johnson, president of MoldTrax Maintenance Solutions and Glenn Keith, MoldTrax’s training and assessment manager, team up for this free webinar to talk about:

- The importance of moving to a 4.0 maintenance culture for OEMs, molders, tool designers and builders, toolroom managers and repair technicians

- The 8 factors of better mold performance

- The value of shop floor language standardization and how to take the first step

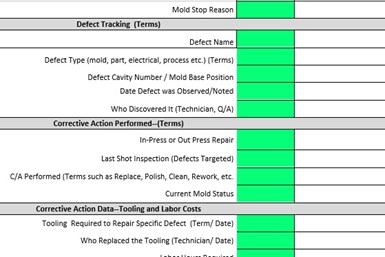

An interactive part of this webinar this scorecard that will be sent to attendees after registration is complete. Presenters will review the components of the test, provide instructions for taking the test and with then reveal and explain the 5 scoring ranges so attendees can gauge their toolroom’s 4.0 mold maintenance documentation capabilities.

When completed, the 5 scoring ranges (Reactive, Basic, Average, Best Practice and World Class) will be displayed on screen, so attendees can see where their toolrooms place on the scorecard. Steve and Glenn will then walk attendees through the industry’s average mold maintenance score and open the discussion up for Q&A.

This should be a good one!

Register Today! Click here to get your virtual seat for the Mold Maintenance Webinar

Related Content

-

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

-

How to Fix Predicted Warpage Before It Happens with Windage and CAD Model Morphing

Applying windage and model-morphing techniques saved toolmaker/molder Sturgis Molded Products the time, cost, headaches of multiple part/mold design iteration loops, cumbersome cooling fixtures, and long molding cycles.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.