Metrics for Assessing Maintenance Skills

Since the job description, qualifications, direction and goals may not be so clear, assessing a repair technician’s value can be confusing. Objective, tangible metrics are a must.

Mold maintenance and repair technicians embody a unique blend of experience, trade skills and attitudes that can be a challenge to motivate, manage and assess. For most mold repair technicians, the job requirement is simple: Get your mold repaired and/or PM’d on time and don’t screw it up. How well this is accomplished is typically a subjective evaluation that can be skewed by personalities and other relationship factors that do not capture the real value of a repair technician.

Since the repair technician’s job description, qualifications, direction and goals are not so clear, assessing their value can be confusing. To be more objective, tangible metrics are a must. These metrics then can be compared to shop averages for all repair technicians to help determine areas of opportunity for more hand skills, machine training or troubleshooting in the eight stages of repair: preparation for preventive maintenance, disassembly, troubleshooting, corrective action, cleaning, assembly, final checking and staging.

A repair technician is hired with the expectation that he has the mechanical skills to disassemble, clean, repair and reassemble expensive molds correctly and safely, but doing all these things efficiently and proficiently is the key. Before we get into metrics, it is important to understand the difference between efficiency and proficiency. It is entirely possible to be efficient but not proficient when it comes to maintenance skills.

A repair technician can fly through repairs, finishing many more molds over time than his or her peers, for a high efficiency rating, yet can create more mold/product issues due to bad habits and careless workmanship than someone else who is slower, but more methodical and a better troubleshooter. The goal for managers is to be able to measure both styles with metrics that tell a story over time.

So, how do we determine efficiency? How do we measure it? How do we use metrics to motivate and challenge technicians? Can we really lower maintenance costs? How much does our maintenance strategy and shop culture influence repair technician performance? Let’s take a look at a few metrics to consider when assessing the skill levels of maintenance repair technicians.

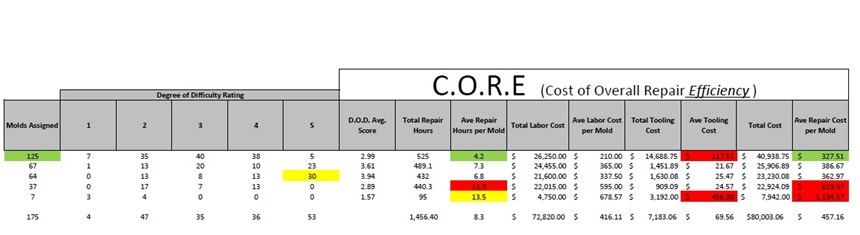

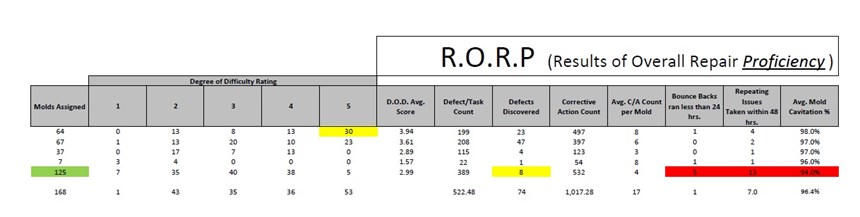

Cost of repair. A popular key performance indicator involves a computerized maintenance management system program that allows the user to predetermine how long a specific job should take for typical mold PM. It then calculates the percentage of time that the repair technician meets the shop’s goals. The problem is that this method only considers the labor hours involved. This means the repair technician’s goal is only to move through the PM quickly, cleaning the mold and replacing tooling, as required.

This method does not accurately reflect the cost-of-repair proficiency score, in which defects discovered, corrective actions, repeating defects, and other results of the repair or PM can be better understood. These figures can then be used in conjunction with cost-of-repair efficiency metrics to create a benchmark for employee/shop comparisons to identify training needs, shop-environment issues or technician compensation. This is a much fairer indicator of overall skill level.

Degree of difficulty. One factor that always gets mentioned in repair-skills assessment is the types of molds on which the repair technician works. Many times, a technician is assigned a mold that is much more challenging than average, and this can lead to hard feelings when his work is compared to (or scored against) that of a technician working on simpler tools. To level the field, our shop created a degree-of-difficulty rating for all molds. Over time, this rating revealed who was being assigned all the hard molds, so we were then able to keep the degree-of-difficulty rating as even as possible throughout the shop.

Each degree-of-difficulty mold rating should be determined by a shop vote, with the manager breaking any ties. We simply post a list of molds on the shop wall and allow the repair technicians to score the molds 1 through 5 (5 being the toughest). This code is then added to the mold number for quick sorting purposes.

Features and run requirements. Repair technicians work repetitively on molds. In other words, there is always another mold to work on when one job is completed. Companies don’t have the luxury of treating every mold repair like a rebuild project with lengthy downtimes and time-consuming inspections. On top of that, mold complexity, and 30 or 40 different tooling configurations running in one basic frame promote a just-in-time culture with short production schedules. These features and run requirements can greatly influence a repair technician’s mold performance rates, so they must be taken into consideration.

It must be said that repair technicians should not be judged on skill competencies alone. Intangibles such as attendance, attitude, integrity, professionalism and a passion to learn should also be considered when it comes to raises or promotions, as many of these qualities migrate into performance metrics when viewed over time. It is important to use specific, controlling, weighted factors of the job to keep things fair and as accurate as possible.

Click here for more on degrees of difficulty classifications.

Related Content

Questions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreRead Next

Maintenance Matters: It's the Manager's Fault

Improving worker engagement starts with leadership at the manager level or, in our case, the toolroom manager.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More