10. How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Are we moving the needle regarding mentoring the next generation of manufacturers? EAB member Marion Wells discusses next-generation workers and the importance of investing in their long-term development in this Q&A.

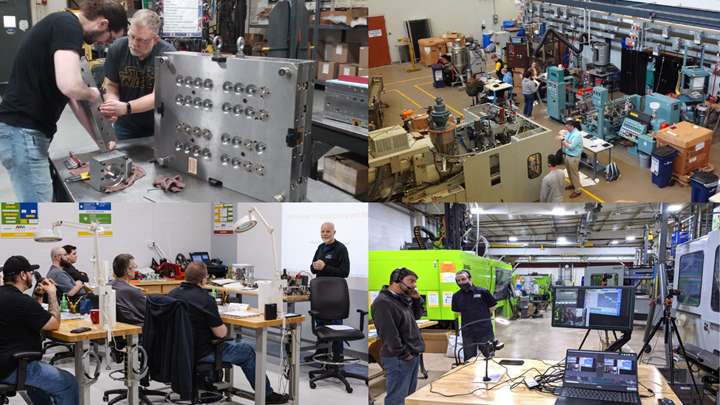

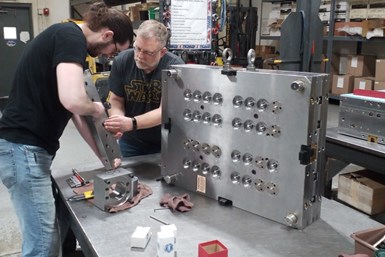

8. The Intersection of Robotics, Hands-on Training in Mold Design Curriculum

In this Q&A—Nick Vitelli, engineering lecturer at Penn State Erie, The Behrend College—touches on workforce development through academic opportunities and discusses the integration of robotics into hands-on training for mold design curriculum.

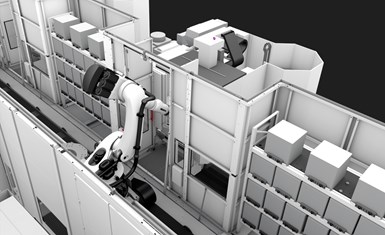

6. Using Automation to Reduce COGS and Stay Globally Competitive

Source: Hermle

By leveraging automation, manufacturers can optimize their operations, improve quality control, and meet the demands of a competitive global market. The article highlights how Cavalier Tool & Manufacturing Ltd. has benefited from implementing automation solutions in various stages of the manufacturing process, ultimately enabling companies to stay ahead in today's competitive landscape.

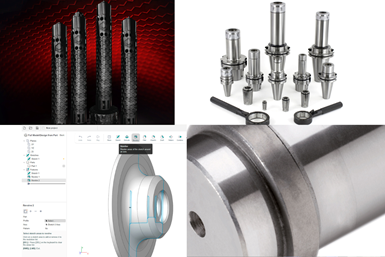

4. Mold Materials, 3D Printing Technologies for Next-Gen Moldmaking

As moldmaking advances, so too do the materials and processes involved in their efficient production. Highlighted here are some of the latest mold materials and 3D printing technologies available to mold and die.

2. Father/Daughter Team Takes Mold Business into the Future

Innovation, personalized service and collective mold manufacturing experience have earned B A Die Mold Inc.’s Alan Petrucci, founder and CEO, and Francine Petrucci, president, customer loyalty for 56 years and set the business up for future success. The father/daughter duo break down the future they see for their shop in this latest profile.

Read Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More