Today’s toolrooms must change from “just git’er done” to a proactive mold maintenance culture with the right process and skills in place. Photos Credit, all images: MoldTrax LLC

As I look back over the past 25 years from behind a bench covered with dirty rags and hand tools, trying to identify the top innovations that have impacted how a repair technician performs his job, I come up short. Unfortunately, getting a mold patched up so we can move on to the next has remained relatively unchanged. This is a shame because one of the most satisfying elements of mold repair is taking a poor-running mold with few spare parts and using your skills to troubleshoot accurately, rework the tooling and mold good parts for as long as necessary. A better, longer running mold fuels the desire to continually do more than “just git’er done.”

Changing the “just git’er done” attitude means transitioning from a reactive to proactive mold maintenance culture. Those toolrooms that have transitioned from a fix-it-after-it-breaks to a reliability-centered culture are reaping many rewards. These companies are molding a higher percentage of quality parts (fewer defects and less scrap); reducing unscheduled mold stops (breakdowns) for cavitation, mold function and other production issues; decreasing tooling costs through more accurate troubleshooting and preventative maintenance (PM) schedules based on a cycle count; lessening labor costs through validation of bench techniques, better equipment and continuous training; speeding up and more accurately justifying new equipment investment, additional resources or a new shop layout; and reducing the learning curve of new repair technicians with a formal training structure.

Toolrooms with a reliability-centered culture are molding a higher percentage of quality parts.

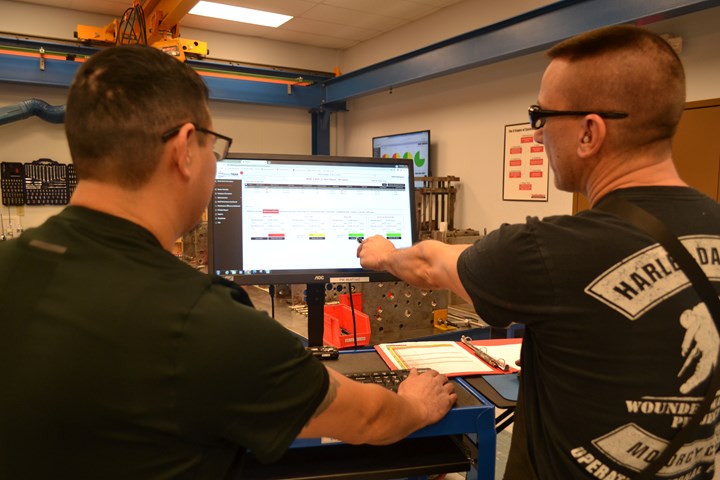

For those toolrooms whose cultural habits remain rooted in reactive maintenance, some widget-type improvements and tools worth mentioning have made the toolroom technician’s job a bit faster and safer. For example, toolroom benches, lighting, better access to utilities and spare tooling, more ergonomic hand tools, wrenches, socket kits, etc., and better mold storage and moving equipment. Improvements also include advances in technology for cleaning water lines, plates and tooling, inspection tools such as coordinate measuring machines (CMMs), microscopes and precision tools, laser welding, engraving and polishing equipment, electric mold separators, and even software and connectivity that offers a myriad of electronic work order systems, cycle counters and mold monitors.

These tools are beneficial, but they do not change the fundamental way a repair technician performs his work if the culture remains reactive. This begs the question: Where does the toolroom of 2023 stand when it comes to its state of mold maintenance? Is your toolroom reactive or proactive?

A better, longer running mold fuels the desire to continually do more than “just git’er done.”

Moving Away from Reactive Maintenance

The common reactive maintenance strategy goes something like this:

- Read a work order comment someone from processing wrote concerning what work the mold needs.

- Disassemble the mold with a variety of hand tools.

- Clean the mold manually and replace tooling components as noted in the comments and (hopefully) samples for part flash, wear or breakage.

- Reassemble the mold and green tag “Ready to Go.”

Many companies are so deeply entrenched with this process and their ability to quickly patch up a mold to get it through the next run that moving away from this reactive culture seems fruitless. Therefore, the first step to secure buy-in from those in charge of maintenance to move away from a reactive culture is to identify the barriers preventing a commitment to a proactive culture.

Equipment improvements that have eased a toolroom technician’s job include toolroom benches, lighting, mold moving devices and access to utilities and spare tooling.

For example, many have no desire to rock the boat. The toolroom manager could be in baby-boomer retirement mode and not want to learn new tricks. Perhaps the staff can’t correctly fill out basic work orders and upper management is not challenging them to do so. Maybe it’s easier to be a good firefighter or everyone is unsure how to start and sustain a proactive culture. Some might think there are so many fires that there is no time to incorporate seemingly idealistic changes — gotta mold parts and get ‘em in the truck! Other shops have too much corporate red tape with best operating procedures (BOPs) and standard operating procedures (SOPs) to embark on any change, and sometimes there are IT (in-house or third-party) roadblocks that snuff out a culture change before it can even get rolling. Does any of this sound familiar?

In my experience, these barriers are usually overcome by toolrooms that are ready to address the high costs and stress level of mold repair patchwork, a younger toolroom manager who sees the need for change, a toolroom manager who is unable to hire experienced repair techs so he needs to train new technicians, custom molders who want to bring in new business or a shop that needs to overhaul the toolroom to handle more complex molds.

This move also takes the right leadership who understands the culture change deliverables, is committed to making changes, has the discipline to do what is expected and accepts the idea that a proactive culture is not a personal choice; it’s part of the job.

A proactive culture removes reliance on tribal mold repair knowledge and focuses on documented mold history.

Once a toolroom moves to a proactive culture, the team experiences improvements in efficiency and attitude. A well-run shop is a team effort that is always more enjoyable and easier to manage. It becomes a team attitude versus individual competitiveness. This shared knowledge fuels talent growth.

This culture also eliminates tribal mold repair knowledge, which eases maintenance scheduling issues. In addition, documented mold history becomes a valuable tool, not a chore. Last but not least, the shop achieves continuous skill improvement through ongoing (and measurable) challenges through the shop and personal performance goals, mold defect targeting and resolutions, structured troubleshooting versus a shotgun approach, root cause analysis versus a “tooling replacer” mentality, and better measuring, stacking and benching (welding, stoning, polishing) skills performing more advanced corrective actions.

Cool new widgets can help achieve this proactive mold maintenance, but it’s the culture and management’s commitment to training that will nurture the toolroom’s dedication to performing maintenance at both the top skill and attitude levels.

Related Content

How to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

Read MoreWhat You Should Know About Injection Mold Safety Straps

Every mold should have one in order to be safe and OSHA compliant.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreRead Next

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreFive Principles that Drive Mold Maintenance Efficiency

Individuals from companies that have embraced systemized mold maintenance share their stories.

Read MoreMaintenance Matters: It's the Manager's Fault

Improving worker engagement starts with leadership at the manager level or, in our case, the toolroom manager.

Read More

.jpg;maxWidth=300;quality=90)