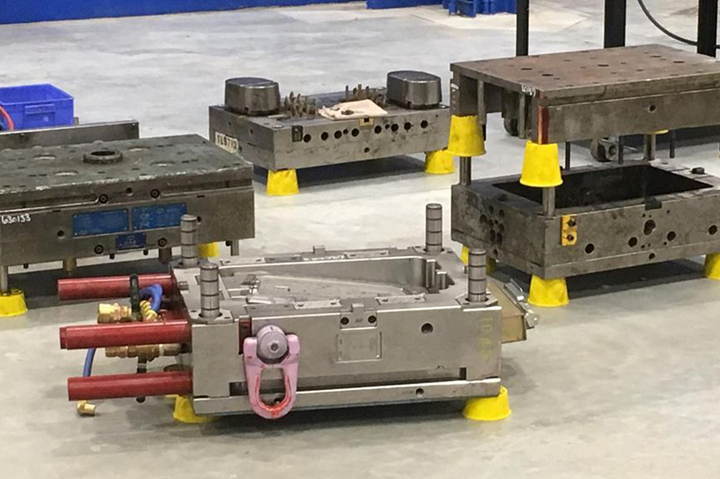

RhinoFeet are a simple, safe and efficient solution for elevating and storing heavy items within the shop. Photo Credit: Progressive Components

Right at the top of the priority list for mold builders and molders is attracting and retaining skilled employees and ensuring that their work environment is safe. Nothing sends a shock through a company and its current employees than an injury on the shop floor. Employees have choices, and the actions of an employer that is continuously walking the walk regarding ensuring a safe workplace will be noticed and appreciated.

For potential future employees, respect can be earned when a candidate initially walks through a safe and clean shop. For student tours and apprentice recruitment, a safe and clean shop addresses the bias that manufacturing is dirty and dangerous.

To address this need, I’ve met industry professionals who have developed products in-house for safer conditions at the mold and across the shop floor and then offered these to the industry at large. Technology suppliers can help bring these products further into the market by converting tribal tricks-of-the-trade into commonly used, safe and standard practices.

At the Mold

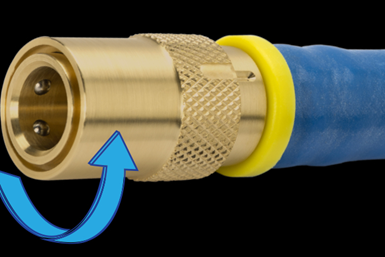

Safety within a shop can begin at the heart of the process: the injection mold. Molds running hot oil can be a hazard. Socket connectors can loosen, resulting in unintended leaks. Some suppliers are now beginning to carry locking socket connectors, where a turn now secures the connection into place.

A locking socket connector where a turn secures the connection into place.

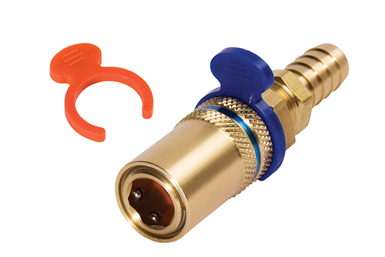

Going one step further, red-colored safety clips lock socket connectors in place, offering a visual to setup personnel and adds intentionality to the connect and disconnect process.

Another mold hazard is with spring-loaded plates, where stored energy can result in a pinch point during assembly. Often, a high number of ejector pins are loaded through the mold’s pin retainer plate, and it can be a balancing act for the plates to remain in place, especially with springs located around the mold’s return pins.

Red-colored safety clips lock socket connectors in place, providing a visual to setup personnel.

To address securing ejector plates into position, Scott Phipps, president of United Tool & Mold (Liberty, South Carolina), developed support pads to assist during mold assembly.

“I saw that it’s awkward to handle plates on the bench and developed a puck-shaped molded part with a magnet on one side to hold onto the plates, and a nut molded into the part to accept a bolt for adjusting to a plate’s height, or, a threaded rod to connect to a second puck. It’s faster and safer than looking around the shop for a 2x4 to stick within the mold’s ejector box,” Phipps says.

RhinoToes help to correctly position plates to avoid pinch points during assembly on the bench.

Knowing that his shop wasn’t the only one battling this, he brought the product to market, dubbing it RhinoToes.

Around the Shop

Before Phipps developing RhinoToes, he looked to eliminate floor hazards within his shop and developed RhinoFeet, which I saw used and mounted throughout his shop during my visit a couple of years ago.

Common shop practice is to repurpose wooden skids used for shipping to the shop floor to place molds onto, raise them off the floor and enable a forklift to reach under and lift. Wooden 2x4s and 4x4s can also be found under molds and plates.

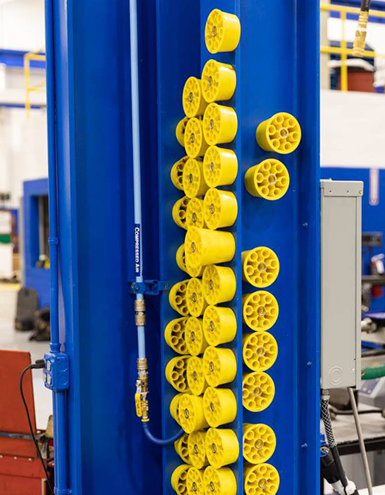

RhinoFeet can be found magnetically held to shop floor beams, benches and CNC machines.

Phipps looked to eliminate wood from the shop floor, as “there’s a lot that’s wrong with placing molds on wood blocks. First, the beam lengths are always sticking out from under the mold, and it is easy for your eye to miss it but your foot to hit it. It’s a trip hazard, and it’s made worse if someone is walking by carrying mold inserts, as then they, and the inserts, go flying,” Phipps says.

These “feet” have caught on. Jim Sperber, president of Master Tool & Mold (Grafton, Wisconsin), first saw RhinoFeet when he visited United Tool & Mold and then looked to rid his shop floor from wood. “When not in use, beams and skids are strewn about a building, even in the cleanest, most organized plants. People are busy with the work at hand, and that can mean wood beams are lying around getting in the way of things and never near where they are needed. So not only is it a hazard but then you also have people hiking all around looking for a couple of pieces of wood and then carrying them back to where that mold is waiting to be placed. Not exactly a clean and safe workplace practice,” Sperber says.

Instead, RhinoFeet can be found magnetically held to a building’s beams, onto toolroom benches and even onto CNC machines.

“There are a lot of little innovations in use in the field,” says Progressive’s President Glenn Starkey, “Suppliers such as ourselves need to further bring them to market to convert tribal tricks-of-the-trade into becoming commonly used, safe and standard practices.”

At the Molding Machine

Changing out a molding machine’s nozzle tips is a routine procedure with every mold setup. Depending on the machine’s carriage stroke and the length of the nozzle body, changing out a nozzle tip can either be a simple task or a knuckle buster.

The owner of Injection Mold Consulting LLC (Philadelphia, Pennsylvania), Jim Fattori, who is also a monthly columnist for MMT’s sister publication, Plastics Technology, is all too familiar with the hazards involved.

“On the smaller machines, setup technicians can have a lot of difficulty getting a wrench on to remove or tighten a nozzle tip,” Fattori says. “Smaller machines have much shorter carriage strokes, which doesn’t leave you a lot of room to work. On occasion, when there is an extended nozzle body screwed into the barrel, the mold must be unclamped from the fixed platen so that the nozzle tip can be tightened from inside the press.

“One trick setup technicians use is to heat up a standard wrench with a torch and bend the end over about 45 degrees. You don’t get a lot of leverage with just a wrench, so a large pipe is slipped over the end to get the proper torque,” Fattori says. “Not only does this take a considerable amount of time, but it also often leads to loose nozzle tips, broken thermocouple wires and foul language.”

Fattori designed an offset slugging wrench with an extended reach, specifically for nozzle tip changeouts, and developed it as a commercially available standard. “When the prototype field tests were completed, I told the lead setup technician he could keep it. That didn’t go over well with other setup guys, but it did lead to a request for five more wrenches.”

This offset slugging wrench with an extended reach was designed specifically for nozzle tip changeouts and developed as a commercially available standard.

Also, at the press, another hazard involves the visibility of a mold’s sharp-cornered inserts and components. In recent years, many shops have upgraded their lighting to improve cleanliness, safety and even morale. “And that’s fine,” Steve Johnson of MoldTrax (Ashland, Ohio) says, “but then, one puts their head between mold halves in a molding press, and things become real dark, real fast.”

Johnson recognized this and presented a range of options at his MoldTrax training classes. “It sure helps to put a lot of light right where you need it, making it a lot safer to change out frontloading inserts, block off gates and clean vents.

“Look for small, adjustable, swivel-type LEDs that have a strong magnet and can be adjusted to any angle quickly, to be able to shine directly into a bore,” Johnson says.

Small, adjustable, swivel-type LEDs have a strong magnet and can be adjusted to any angle quickly to put light where you need it.

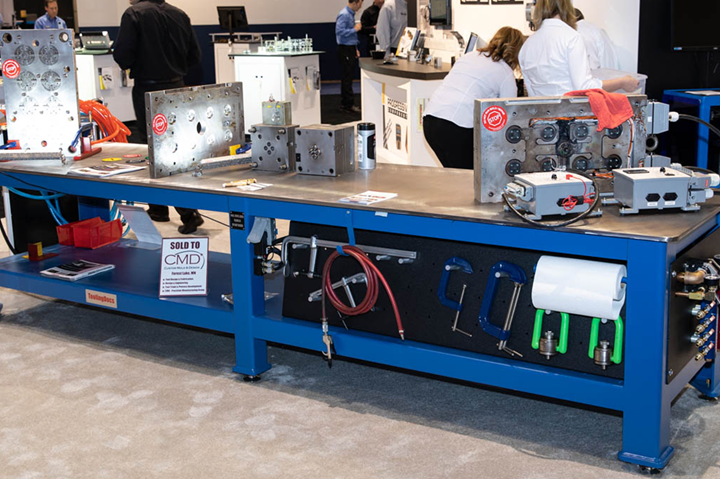

In many plants, the toolroom can be full of secondhand, leftover equipment. Because this area is where a company’s tooling investment is maintained, Johnson developed standard, preconfigured toolroom benches specifically for mold assembly and disassembly.

“Benches engineered for this application not only provide an ergonomically correct work area for those working at them day in, day out, but also eliminate clutter by providing storage for commonly accessed tools and supplies,” Johnson says. “And, trip hazards are reduced by configuring benches with water manifolds, air manifolds and electrical connections.”

Standard, preconfigured toolroom benchs specifically for mold assembly and disassembly.

Putting Measures in Place

Investment in maintaining a safe workplace shows that a company values its employees by reducing hazards and accidents throughout the shop. The products and approaches I reviewed here are just a few that have been developed at the front lines by longtime toolroom and molding professionals and today are available as standards by mold technologies providers.

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Throwback Thursday: Skills Center: Apprentice Training - Shop Safety

It’s never a bad time to revisit features that remind us of the importance of safety in a shop environment.

Read MoreDo You Know the Hidden Costs of Poor Quality?

Mold builders must fully understand and account for the hidden costs of poor quality or risk losing customer trust, brand reputation and business value. Quality management is a business optimization tool to help address both the visible and invisible costs.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More.jpg;maxWidth=970;quality=90)