Across the Bench - The Plan Comes Together

The repair sheet is critical to the success of any mold repair plan.

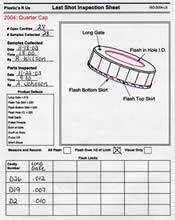

| The final step in creating our mold repair plan is to correlate the mold performance data gathered during the production run (injection mold layout sheet) and last shot inspection results that we discussed in last month's article. This will give us a list of targeted product defects that will require corrective action. These are listed separately, under Defects, by cavity I.D. number onto the bottom left of the repair sheet (Figure 1). The repair sheet shows how different aspects of maintenance information are separated for a clearer picture of not only what defects need repairing, but also what other work needs to be done to the mold as seen in Maintenance Instructions (top center).

Quick ReferenceIt is important that the repair plan worksheet is formatted so that it is simple and easy to understand. Repair technicians must be able to quickly reference past defects and corrective actions; they seldom have the time or patience to sift through scribbled journal entries or coded work requests to decipher past maintenance tasks. Therefore, critical to the success of any repair plan are the worksheets used by the technicians during repairs. If these worksheets lack definition, critical information does not get documented. If they are complex or confusing and do not follow the logical flow of the job, information will be inaccurate or missing, thus the documentation method will not be accepted by repair personnel, which in turn will defeat all efforts to systemize mold maintenance. On the repair sheet, all run time information is displayed on the left side of the sheet. The color-coded mold map on the right side prominently displays the location and type of the noted product defects and includes a legend for visual conformation. Color coding defect locations is a great way to highlight patterns and trends in muticavity molds. Researching past defects and positions is quickly accomplished by comparing past mold maps. Going a step further and entering these maps into a database allows you to flip back through the maps very quickly, scanning for repeating defects or locations. Here's a tip: during the troubleshooting stage of mold or product defects, it is sometimes just as important to see quadrants or specific areas of a mold where defects don't occur (see Troubleshooting table at end of article).

More Than Targeting DefectsCorrecting product defects is only part of a comprehensive repair plan. Other repair objectives include continually improving mold performance and reliability by monitoring the mold frame/base condition during repairs. Leader pins, bushings, interlocks and early return mechanisms should be checked for excess wear and galling. Mold plates should be checked for straightness, hobbing, corrosion and water line buildup. Tooling vent paths and dumps should be periodically checked for hobbing and correct depth. Hydraulic cylinders should have internal seals replaced before they leak. Keeping mold tooling clean and aligned will also maximize tooling life, simplifying, troubleshooting and routing repairs allowing you to better schedule repair time for known mold frame or tooling issues. Obviously, production requirements will not allow all these objectives to be addressed at every C/R (Clean and Repair) or whenever a mold is pulled. To take full advantage of allotted downtime, you must be acutely aware of mold condition, problems and characteristics so that you may systematically begin to establish total mold control, by repairing all you can. Levels of disassembly are based on cycles or run time and must be defined for every repair so that molds are not overmaintained. Complete disassembly of all plates and tooling every time a mold comes into the shop is an enormous waste of time and subjects expensive tooling to damage during handling and cleaning operations. Conversely, some mold components need to be specified for removal and cleaning to ensure that they will not be overlooked during a C/R. Each mold's C/R level of disassembly is dependent upon observed internal residual contamination, tooling wear and grease condition after a specific number of cycles or hours are run. There are three levels of disassembly for most molds: wipedown, general and major. The tooling and plates requiring disassembly for cleaning during these three levels is always mold specific, for example: 1. A wipedown level of disassembly is performed when the mold runs less than 10,000 cycles

|

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreLine Width vs. Depth Ratio in Laser Engraving

A laser does not produce 90-degree sidewalls. It requires a certain amount of draft in order to produce the required pattern.

Read More5 Hot Runner Tips for Moldmakers and Molders

Best practices for initial hot runner tryouts and effective preventive maintenance.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Across the Bench - Creating a Repair Plan

The last shot is the most important key to insuring accurate mold repair.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More