Photo Credit: Getty Images

MoldMaking Technology always has something to offer readers, whether its about switching to five-axis machining, investing in additive tooling and automation, celebrating the new wins in next-generation hiring, training and project collaborations or improving an Industry 4.0 culture. Moreover, despite setbacks caused by COVID-19, this year’s content has revealed that moldmakers have been all but idle.

Below are the top ten most-viewed articles of 2021. Based on analytics, these have been considered the most popular posts. However, this is just a small portion of the content MMT covers online and in monthly print issues.

Click the links below in case you missed any of these features or want a second look. For more archived content visit MMT’s articles tab.

10. Automation Opens Door to New Possibilities and Need for More People at Minnesota Mold Builder

Increasing automation throughout the shop with both palletization, EDM and five-axis machining has allowed Mold-Tech to grow in technology, throughput and people.

Photo Credit: Mold-Tech

This profile, which can be found in the March 2021 issue, tells the tale of Mold-Tech Inc., which has served the injection molding industry, designing, building and sampling the highest quality injection molds since 1978. Dave Park, business development/sales at Mold-Tech reflects on what he believes in the company’s chief competitive advantage(s), their approach to training employees, the company’s most valuable assets and latest technology focuses to name a few topics.

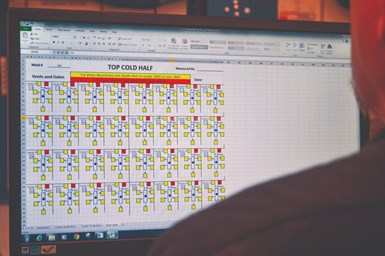

8. What is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Photo Credit: MoldTrax

In Part 1 of this article series, MoldTrax President Steve Johnson reviewed the various maintenance cultures found within shops, identified necessary mold data and explained the inadequacies of journal-entry systems. Alternately, Part 2 digs deeper into data collection and how “moving to a more data-driven, 4.0 or scientific type of maintenance culture avoids this type of manual labor [non-standard language].” Also find this feature in the March 2021 edition.

6. 2021 Leadtime Leader Award Winner: Westminster Tool—Perseverance with a Plan

Westminster Tool’s latest commitment to the plan—investment in new technologies, processes and capabilities, workforce development/training and sales & marketing—helped them edge out this year’s competition.

Congratulations to our 2021 Leadtime Leader winner! MMT was able to visit the Westminster Tool gang in Plainfield, Connecticut, back in August (and feature them in the September 2021 issue) to get the scoop on their investment plan, past, current and upcoming projects and an outline of the company’s technologies, processes and capabilities.

“While we have enhanced service offerings to include pre-and post-manufacturing services, we have not lost sight of the importance of building high-quality injection molds that will provide in-spec, dimensionally stable parts shot after shot,” Westminster Tool President Ray Coombs Jr. says. “Our thorough, proactive and hands-on process enables us to get involved at the inception of a project and partner with our customers to provide a manufacturing solution as unique as the challenge.”

Photo Credit: Westminster Tool

4. How to Produce More Accurate Molds and Reduce Rework

Photo Credit: Steel 21

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Back in February 2021, Steel 21 unveiled its patented micro-milling process for manufacturing steel plate flat and parallel, features that helps mold builders shorten mold build times and increase accuracy.

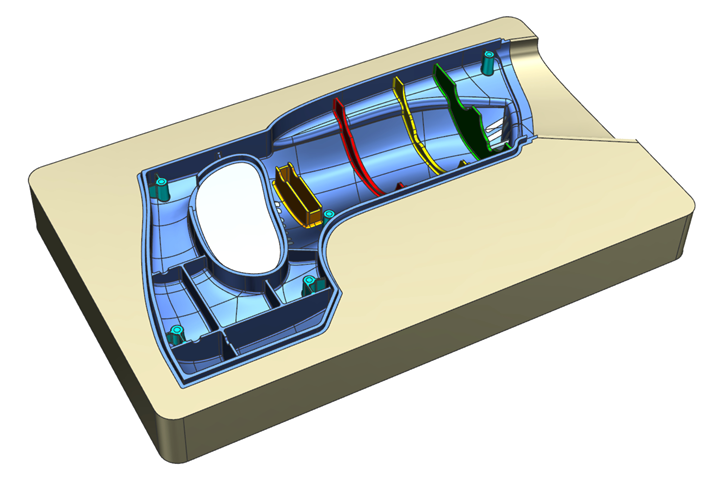

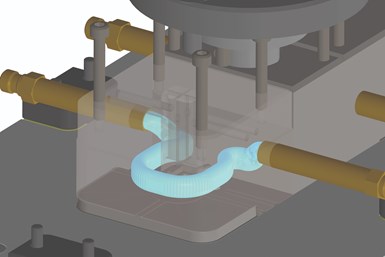

2. Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Eden Tool, a 12-person medical mold builder, known for its high-end EDM, grinding and hard milling capabilities, is about predictable manufacturing, and hard milling is a powerful tool in the toolbox of predictable manufacturing. “We don't just mill hard materials. Hard milling is part of our predictable manufacturing process,” Mike Eden, owner of Eden Tool Company, says.

In this feature (found in the February 2021 issue), Editorial Director Christina Fuges explains Eden Tool’s history as a mold builder, its investment in hard milling and how they have moved into medical component manufacturing.

Photo Credit: Eden Tool Company

Read Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More