Mold maintenance has moved up the priority list of many toolrooms across the mold manufacturing supply chain this past year, so in addition to MoldMaking Technology’s three-part Scientific Maintenance article series with mold maintenance expert Steve Johnson of Mold Trax, we thought a webinar was in order to dig a little deeper. Photo Credit: Mold Trax.

Does your toolroom have a Reactive, Basic, Average, Best Practice or World Class culture when it comes to collecting and using Industry 4.0-type mold maintenance documentation? Steve Johnson and Glenn Keith of MoldTrax will help you answer that question during this FREE webinar on March 30 at 2PM EST.

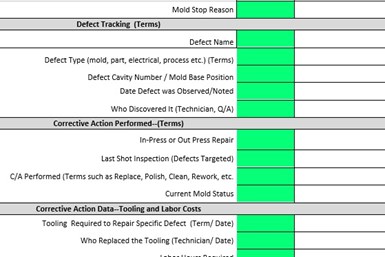

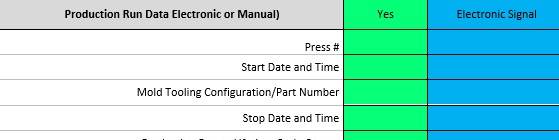

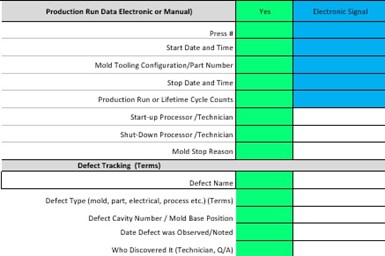

This duo will tag team to not only review the changing mold maintenance landscape, explain the importance of a 4.0 culture, break down the 8 factors of mold performance, provide examples of “futile” work order systems and why they don’t work, instruct how to create standard terms and use them in your current ERP system, they will also deliver a test to each attendee upon registration to be explained and taken during this presentation.

When completed, the 5 scoring ranges (Reactive, Basic, Average, Best Practice and World Class) will be displayed on screen, so attendees can see where their toolrooms place on the scorecard. Steve and Glenn will then walk attendees through the industry’s average mold maintenance score and open the discussion up for Q&A.

This scorecard/test that will be sent to attendees after registration is complete. Presenters will review the components of the test, provide instructions for taking the test and will then reveal and explain the 5 scoring ranges so attendees can gauge their toolroom’s 4.0 mold maintenance documentation capabilities.

Photo Credit: MoldTrax.

Primary Topics:

- The importance of moving to a 4.0 maintenance culture for OEMs, molders, tool designers and builders, toolroom managers and repair technicians

- The 8 factors of better mold performance

- The value of shop floor language standardization and how to take the first step

Presenters:

Steve Johnson is the President of MoldTrax Maintenance Solutions, a provider of maintenance training products and services. With 40 years of experience in the tooling industry, including eight years as senior tooling engineer for Abbott Laboratories/Hospira and 24 years as a toolmaker at Calmar Inc., repairing and rebuilding high cavitation close-tolerance multi-cavity molds. Prior to Calmar, Steve served six years in the U.S. Navy working as a jet mechanic on the A4L Sky-hawk, and majored in mechanical engineering at Southern State University. He has also designed and developed MoldTrax, a leading documentation software system for tracking mold performance and maintenance, and author’s many articles for plastics industry magazines.

Glenn Keith has 35 years of experience in mold maintenance, including a four-year apprenticeship, then 15 years as a repair technician repairing and rebuilding blow molds, injection molds and various hot runner systems for the automotive, caps and closures and packaging industry at Whirley Drinkworks, Erie Plastics and Loranger Manufacturing. He then moved into management where he supervised the mold repair area for 16 years. Today Glenn is a training and assessment manager for MoldTrax LLC where he conducts Maintenance Capability Assessments for companies around the world and also trains on the implementation and use of the MoldTrax maintenance software—MTWEB.

Related Content

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreBreaking Down 3D Scanning in Moldmaking

Identifying 3D scanning requirements and implementing the appropriate technology.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreRead Next

What Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)