Husky Technologies

500 Queen St. S

Bolton, ON L7E 5S5 CA

905-951-5000

sales@husky.co

husky.co

About Husky Technologies

Whatever you need, Husky will make sure you get it—quickly, courteously and accurately. Project management or factory planning services. Design and development assistance. Careers and internships. Media inquiries and more.

IS THIS YOUR COMPANY?

Video Gallery

Customer Testimonial | Kriya Technologies - Medical Injection Molding with ICHOR

Discover how Kriya Medical Technologies Pvt. Ltd. successfully deployed the first ICHOR™ system. This advanced system ...

Ultra SideGate 2.0 Technology | Easier installation and maintenance for lower cost of ownership

Ultra SideGate™ 2.0 Technology Advantages: Injection molding solutions for temperature uniformity, and precise gate control.

Merry Christmas and Happy Holidays from Husky! 🎄🎅🏼

Here's to the memories you've created with those you hold dear, celebrating the joyous moments and the priceless gifts ...

Optimize Injection Molding with Husky Genuine OEM Hydraulic Hose Kits | Boost System Performance

Ensure your injection molding systems run at peak performance with Husky's genuine OEM hydraulic hose kits. In this video ...

As Seen On MoldMaking Technology

Husky Technologies Supplies the Following Products

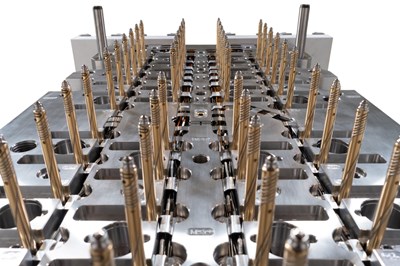

- Hot Halves

- Hot Runner Manifolds

- Hydraulic Valve Gate Nozzles

- Mechanical Valve Gate Nozzles

- Mold Bases and Frames

- Mold Flow and Simulation Software

- Pneumatic Valve Gate Nozzles

- Servo Valve Gate Nozzles

- Temperature Controls, Monitors, Sensors

- Thermal Edge Gate Nozzles

- Thermal Hot Tip Nozzles

- Thermal Multi-Gate Nozzles

- Valve Gate Controllers

- Valve Gate Sequencers

Editorial, News, and Products

-

How to Use Hot Runner Balance in Mold Qualification

If you are interested in the impact of system and hot runner balance on part quality, the causes of unbalanced hot runner systems and short shot parts, the procedure for measuring system balance and the impact of application specifics on system and hot runner balance expectations, then tune into this on-demand webinar.

-

VIDEO: Sustainable Molding and Advanced Gating

Hot runner supplier emphasizes sustainability in bio-resin molding, custom side gating and valve gate technologies.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

How to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

-

Advancing Moldmaking and Plastics: Trends in 3D Printing, Automation and Sustainability

NPE 2024 showcased the latest trends and technologies in innovation, efficiency and sustainability for moldmakers and molders, featuring advancements in 3D printing, automation, design and virtual reality/augmented reality/artificial intelligence.

-

Mid-Year Look at Technologies Available for Your Mold Shop

One of the key foundations of any successful business is the technology and equipment it implements to achieve a final product. The following suppliers are providing new and improved solutions that could advance your business.

-

PET Injection Molder Introduces rPET Capabilities

Husky Technology’s HyPET6e design strives to provide customers with sustainable options, including enhanced energy efficiency and closed-loop quality control.

-

Hot Runner System Demonstrates More Precise Melt Control

NPE2024: Husky Technologies debuts the Ultrashot injection molding system, designed to increase overall part design freedom with high scale and quality.

-

Husky Celebrates Opening of State-of-the-Art Service Center in Indiana

The injection molding equipment and services provider augments its operational and service capabilities in the Americas, reaffirmed by 70 years in business.

-

Combining Innovation and Artistry to Build Complex, Precision, Multi-Cavity Molds

This Florida mold builder is about high-performance, high-precision moldmaking by blending craftsmanship with technology.

-

Hot Runner Tips, Apprenticeships & Waterline Maintenance, Oh My! MMT's June Top Hits

Take a look at MMT’s top hits from June based on Google Analytics.

-

VIDEO: Hot Runner Maintenance Tips

Scott Clark, Hot Runner Business Manager for Husky Technologies, breaks down maintenance practices for hot runner systems.

-

PTXPO 2023 Preview: Advancing the Mold With Featured Mold Component, Hot Runner Technology

There’s no doubt mold components and hot runners are important parts of the moldmaking industry. This preview gives mold buyers, mold builders and injection molders a look into PTXPO exhibitors displaying these technologies at the show.

-

Husky Technologies Showcases Innovation Injection Mold Solutions at MD&M West 2023

This week, MD&M/Plastec West attendees can survey Husky’s latest technologies and services engineered for medical device manufacturers.

-

MMT Ask the Expert: How to Succeed with Complex Resins Such as Bioresin and PCR in Injection-molded Applications

In this Ask the Expert brought to you by Husky, Sheldon Alexander answers questions about complex resins. The use of complex resins such as bioresins instead of petroleum-based resins continues to trend in our industry, and it is important to understand the challenges that can arise. This episode is brought to you by Husky, Melt to Mold Precision.

-

MMT Ask the Expert: Hot Runner Benefits and the Fundamentals of Maintenance and Refurbishment

In this next portion of our “Ask the Expert” series, Husky’s Derrick Hennebicque answers some FAQs about the advantages of hot runner systems and refurbishment strategies. This episode is brought to you by Husky, Melt to Mold Precision.

-

MMT Ask the Expert: Servo Control and Hot Runner Temperature Controller Best Practices

In this portion of our “Ask the Expert” series, Husky’s Vernon Moss answers some frequently asked questions on servo control and hot runner controllers. This episode is brought to you by Husky, Melt to Mold Precision.

-

MMT Ask the Expert: How to Optimize System and Hot Runner Balance

In the first portion of our “Ask the Expert” series, Husky’s Sheldon Alexander answers some frequently asked questions on the fundamentals of system and hot runner balance and how to overcome challenges. This episode is brought to you by Husky, Melt to Mold Precision.

-

Second-Generation Control Algorithm Elevates Mold Controller Performance

Husky launches a new control algorithm for its line of Altanium mold controllers, with 42% faster heat-up times, 30% less energy use and reported 64% increased productivity.

-

Thermally Sensitive or Corrosive Applications are Combatted by Hot Runners

Combined with Husky Technologies’ experience, guidelines and analysis tool, the company’s new UltraMelt hot runner technology meets the processing needs of challenging resins and demanding applications.

-

Learn About Industry Topics and Emerging Technologies at PTXPO

Aside from being a great opportunity to network with other industry professionals, PTXPO will have numerous educational sessions about hot topics and emerging technologies.

-

Real-Time Monitoring Service Added as Standard Feature to PET and Closure Systems

Husky Injection Molding Systems includes Advantage+Elite as a standard system feature on all PET and Closure systems to accelerate the shift of producing increasingly sustainable packaging.

-

Amerimold 2021 Post-Show Flashback: Build

MMT looks back on the return of an in-person Amerimold in September after a year-long pandemic.

-

Husky Introduces UltraShot Hot Runner Injection Molding System

Amerimold exhibitor features the advanced technology which permits more precise melt control and the ability to produce identical, repeatable performance in every cavity.

-

Servo Control Feature Facilitates Precise, Controlled Mold Actuation

Husky’s electric servo control feature for the Altanium mold controller series serves to increase mold life and provides instant access to motion performance.

-

Melt Delivery and Control System Enables Ultimate Design Freedom

Scalable to 128 cavities, Husky’s UltraShot Injection System offers the injection molding process unconstrained part design and risk-free scalability.

-

Adaptive PET Preform Mold Meets Fluid Production Requirements

To meet continuously changing consumer demands, Husky highlights the NexPET system which supports a wider variety of applications, more SKUs, shorter production runs and more frequent design changeovers.

-

Valve Gate Nozzle Offers Exceptional Wear Resistance

Adding to Husky Injection Molding Systems’ Ultra Helix Valve Gate nozzle lineup, the Ultra Helix 250 T2’s advanced design minimizes wear, provides high gate quality and longevity.

-

Customizable Mold Controller Meets Adaptive Equipment Needs

Husky Injection Molding Systems’ most recent Altanium Neo5 mold controller provides a Basic and Advanced setting to tailor to an operator’s specific needs and skill level.

-

Mold Controllers with Virtual Network Computing Enables Remote Access

Husky Injection Molding System’s Altanium mold controllers are now available with virtual network computing (VNC) options.

-

Noteworthy News: Growth Spurts

From new facilities dedicated to automation, training and distribution to new hires eager to tackle building relationships through providing excellent customer service, the industry innovators below are growing all across the United States, Canada and Mexico.

-

Noteworthy News: Giving Back

It’s a time for giving thanks, so send a shout out to companies like DMG MORI, Big Kaiser, Mazak Corp., Mitutoyo America Corporation, Husky Injection Molding Systems and more for giving back to their communities and industry!

-

Noteworthy News: Congrats are in Order

From anniversaries to new hires to awards, MoldMaking Technology has the latest news in industry success stories.

-

Getting Hot and Heavy during a Little Hot Runner Training

If a mold is the heart of a molding system, then the hot runner system is the heart of a hot runner mold, and I recently learned that there is a lot to know when it comes to designing and maintaining these systems to ensure optimal mold and part quality and performance.

-

Tech Trends: K 2019 Sneak Peek, Part 4

Here’s just a quick sneak peek at some of products exhibitors like Husky, Frigel, Barnes Molding Solutions brands and Hasco will be displaying in their booths at K 2019.

-

Injection Molding Solutions Designed to Meet Global Demands for Plastic Production

Husky Injection Molding Systems will feature solutions for every market need, focusing on new, innovative technologies that meet the changing global demands of plastic producers at K 2019.

-

Tooling Technologies Offer Value, Productivity and Flexibility

Husky will be running its new HyPET HPP5e system at K 2019, designed to delivering better energy savings, system reliability, preform quality and user friendliness.

-

MoldTrax Hot Runner Extravaganza Delivers on Expertise and Education

The “Who’s Who” in processing and hot runner technologies turned out to educate attendees with well-honed wisdom and experience.

-

2018 Technology Review and Sourcing Guide: Hot Runners

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including hot runners.

-

NPE2018 Video Recap: Exhilaration, Innovation and Inspiration

MoldMaking Technology’s editorial team recaps some highlights from the show floor at NPE2018, including a technology slideshow, seven podcasts recorded live from the event and a video.

-

Successful Supplier Nights Help "Mold" Careers

The Chicago Chapter of the American Mold Builders Association (AMBA) recently hosted its fourth successful supplier night fundraiser that continues to provide much-needed support for promoting careers in moldmaking.

-

Hot Runner Technologies Aim to Simplify Moldmakers’ Approaches

Hot runner suppliers are developing solutions that remove complexities from the way that moldmakers and molders design, control and maintain their processes.

-

Throwback Thursday: How to Prevent Hot Runner Leaks

One of the more common concerns still expressed by molders today about hot runner molds is the threat of a leak of molten plastic causing the manifold pocket to fill. Here is a throwback to an article on leak prevention focused on externally heated hot runner systems.

-

Mexico: Manufacturing Mecca to the South

A mold-building perspective on Mexico’s manufacturing opportunities, trends and challenges.

-

Optimize High-Performance Polymer Molding

When molding high-temperature resins, direct gating with a hot runner system can save molders time and money.

-

SLIDESHOW: Technology Showcase, MMT Surprise

This week's slideshow is an MMT 'Surprise' Showcase, editor’s picks for the week.

-

SLIDESHOW: Technology Showcase, After K

By all accounts K 2016 was a success. According to show management, attendees were delighted with the wealth of new technical developments presented by raw materials producers, machinery manufacturers and producers of semi-finished and technical parts. Here are some technology highlights.

-

SLIDESHOW: Technology Showcase, A K 2016 Preview

As K 2016 quickly approaches, we’re providing a preview of a few of the products that will be featured there from October 19-26 in Düsseldorf, Germany.

-

A Look at Self-Cleaning Mold Technology

A self-cleaning mold feature helps to eliminate hundreds of hours of mold maintenance a year, while reducing the risk of damage to the mold and making the cleaning process safer.

-

Cleaning in a Flash

Self-cleaning technology uses controlled flash to make mold maintenance faster, easier and safer.

-

Direct Side Gating

Mold builders and molders should carefully consider hot runner selection, as it dramatically impacts an injection molding system’s speed, quality and uptime.

-

Achieving Accurate Temperature Control with Your Hot Runner Controller

The right hot runner controller is key to producing high-quality, complex medical parts.

-

Compatibility Makes Technology Upgrade a No-Brainer

The ability to employ previous-generation tooling is just one of many notable features of Husky's latest PET preform injection molding system.

-

Case Study: Hot Runners

New Hot Runner System Solves Side-Gating Issues

-

Selecting a Valve Gate Hot Runner

A look at valve gate plate actuation technology for consistent part filling, excellent gate quality and close nozzle spacing.

-

The Right Side-Gating Solution Delivers Maximum Value to Your Customers

When it comes to side-gate hot runners, it is important to look at the options, their benefits and then compare against your customer’s needs.

-

Collaboration Leads to Complete Turnkey System

To meet the special needs of this project, ICU, Husky and Tech Mold worked together to design a complete turnkey system—including machine, mold, hot runner and temperature controller.

-

Going Beyond the Basic “Blue Box”

The old blue box temperature controller is simply no longer an acceptable option for many molding operations.

-

Gain Access to the Recession-Proof Medical Market

Moldmakers who want to diversify into medical—or maintain their competitive edge—need up-to-date, high-tech engineering and fabrication capabilities in order to meet the toolmaking industry’s most stringent quality standards.

-

Trends in Hot Runner Technology

Quality, performance, maintenance and flexibility are driving today’s hot runner technology.

-

Complex Molds Mean Business for High-Tech Toolmakers

Focus on cavitation and advanced product design gives progressive mold shops a jump on competitors.

-

Electrically Actuated Valve Gates: An Emerging Hot Runner Technology

Electrically actuated valve stems promise more control, cleaner actuation, closer pitch spacing, higher quality gates and reduced maintenance.

-

Lean Manufacturing Trims Leadtimes

Moldmakers aren't the only ones reducing leadtimes. Component and hot runner suppliers are delivering their equipment and supplies faster to accommodate industry demand.

-

Complex Parts Put a Premium on High-Tech Mold Design

Equipment and component suppliers are developing a range of products for advanced moldmaking needs.

-

New PET Bottle Standard May Boost Business for Moldmakers

A rule to lightweight preform necks and closures could require more than 1,000 new molds.

-

Hot Runner Application Review Leads to Successful Processing

Successful application of a hot runner in the molding environment requires detailed analysis of gating styles, resin and molder expectations.

-

High Cavitation Molds Promote Economies of Scale

Toolmakers are developing increasingly complex molds for high production of thinwall parts.

-

Advances in Hot Runner Systems Drive Innovations in Part Engineering and Styling

Design and performance capabilities of components fabricated in state-of-the-art molds enhance the appeal of new vehicles.

-

Hot Runners Shrink Leadtimes, Cut Costs

Standardized hot runner system allows the moldmaker to easily configure a system in just two weeks.

-

Get the Most from Your Tooling Investment

Alignment, mold protection, tonnage distribution and injection control are the main elements in the molding machine that could affect your tooling investment.

-

Maintaining a Strong Relationship with Your Hot Runner Supplier

Once your hot runner supplier is chosen, you need to take the proper steps to maintain a mutually beneficial, long-term relationship.

-

Advancing Mold Performance Using Hot Runner Technology

A quality hot runner system is one of the more important enhancements you can incorporate into a mold to improve molded part quality, reduce production times and remain price competitive.

-

How to Design Hot Runner Plates

Moldmakers are often required to design and make hot runner plates for molds. Being aware of these best practices can make the process easier.

-

Why Choose a Valve-Gated Hot Runner?

Moldmakers need to be aware of how different gating technology can affect their customers when designing a hot runner system into a mold.