How to Use Hot Runner Balance in Mold Qualification

If you are interested in the impact of system and hot runner balance on part quality, the causes of unbalanced hot runner systems and short shot parts, the procedure for measuring system balance and the impact of application specifics on system and hot runner balance expectations, then tune into this on-demand webinar.

Sheldon Alexander, the Business Manager for Hot Runners and Controllers for Husky Injection Molding Systems dives deep into the ins and outs of system balance. In addition to the presentation, Sheldon provides answers to the following audience questions, which might be your questions too. So register for free to listen to on-demand webinar:

- When we are using a valve gate system and have visual defects like gate burns or flow marks, how can we resolve this problem?

- How do the balance numbers of a hot runner system compare to a cold runner system?

- Does adjusting nozzle temperature help with balance in valve-gated systems as it does to thermal tips?

- Which is better, a valve gate hot runner or a servo motor gate hot runner?

- In some cases would there be some benefit to running a 50% short shot calculation?

- How do you thermally balance 10 drop vs 16 drop manifold? This is for HT system.

- Which is better a valve gate system running from 1 pneumatic input or a valve gate system with pneumatic inputs for each nozzle?

- How do you determine the right switchover point in 95% fill method?

- Could you please explain how melt flow is automatically adjusted when we fill mold 90% to 95%?

- Doesn't an increased percentage of fill mask a potential system issue in short shot balance?

- At what point in the qualification would you stop the process?

- For stack molds, I normally leave one side of the mold part thicker than the other to balance the weight. So does Husky do something to help that on the HR system for stack molds?

- How do you evaluate hot runner balance through a hot-to-cold application?

- What are your recommendations for tonnage on multicavity molds?

- What is your experience with PC applications especially for high-end medical parts and what have your observations been on system balance for these types of applications?

- Have there been any recent application or part design trends that have created new challenges with system balance? And how do you overcome these challenges?

- What impact does shot size have on system balance? Are there challenges with very small parts?

- What is your experience with high cavitation stack molds and system balance?

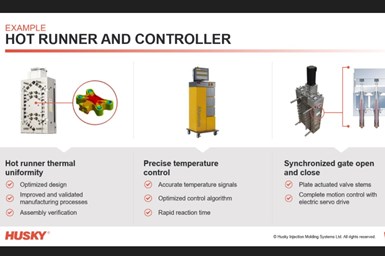

- What does Husky do to ensure that its systems are balanced?

- What can be done with the process to improve the systems balance?

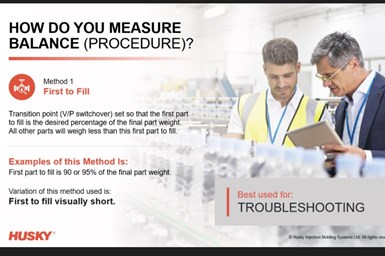

- What procedure does Husky recommend to check systems balance?

Click here to view this webinar for free.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

How to Determine the Proper Vent Depth

Vent depth is critical to optimizing mold performance, so here is one approach to finding that elusive right number.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)