The Right Side-Gating Solution Delivers Maximum Value to Your Customers

When it comes to side-gate hot runners, it is important to look at the options, their benefits and then compare against your customer’s needs.

As a moldmaker, being able to deliver the most value to your molding customers is critical to differentiating yourself and gaining a competitive advantage in the market. One of the best ways to do this is to provide customers with a solution that offers them increased productivity, saving them time and money by using the latest technologies.

Supplying a solution that provides greater productivity requires not only designing and manufacturing high-quality, high-performance molds, but also selecting a hot runner that performs at the same high level and meets the customer’s needs. Hot runners are one of the most important components

in a mold and have a significant impact on cycle time, part quality and uptime. As a moldmaker, if you’re looking to provide an optimal solution to customers, it’s imperative to give careful consideration to the hot runner used in the mold.

Side-Gate Hot Runners

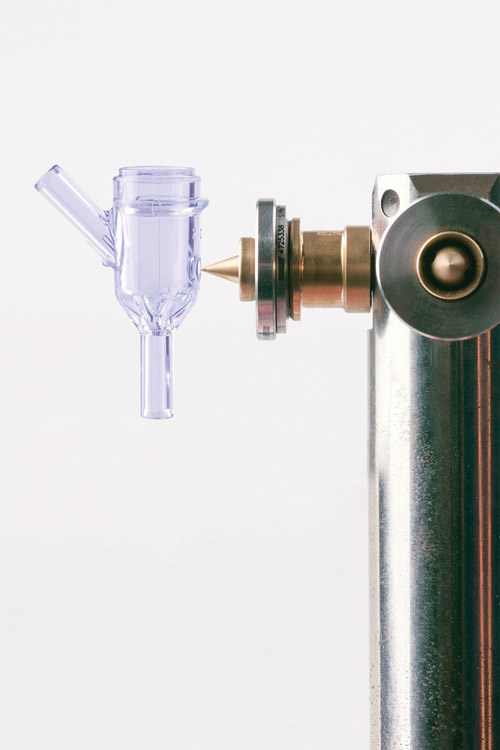

The hot runner market is constantly evolving, with suppliers always looking to develop innovative solutions to addressmarket demands. Simple side-gate hot runners have been around for some time, but more recent developments further enhanced the available technology to allow moldmakers to direct gate parts that previously were gated with a cold runner.

Direct side gating is suited for deep draw parts such as pipettes and syringe barrels or for small parts like medical infusion components. Side-gate hot runners provide a key benefit for these types of applications by allowing the direct gating of parts that would otherwise require a cold runner.

This saves both resin and typically cuts cycle time by up to 50 percent. In addition, it eliminates the need for downstream processing of the cold runner, which especially in medical applications, can typically not be used as regrind. The part quality achieved by direct gating with a side-gate hot runner is in many cases improved over parts manufactured with a cold runner.

With many side-gate product variations available in the marketplace, it is important to look at the different design options, the benefits each offers, and compare them against your customer’s needs as well as the needs of the specific application. By carefully evaluating each and integrating the side-gate hot runner that best suits your customer, you’ll help to position yourself as a valuable partner to their business.

Part Quality

Part quality is always a priority for molders, and is particularly important in the medical industry where side-gate hot runners are often used. Quality is so critical here—primarily due to safety, which is always a huge concern. With medical parts, sharp edges or pronounced gate vestiges can potentially tear latex gloves or even skin. In the medical industry, even seemingly small improvements in quality can make a significant difference in everyday applications and their safety.

Gate quality is one of the areas where parts are scrutinized and carefully evaluated, since this is where excess plastic and sharp edges are most common. With the hot runner having the largest impact on gate quality, it is important for moldmakers to carefully evaluate which side-gate hot runners can deliver the quality that customers require. There can be a significant difference in gate quality between various sidegate hot runners. The available operating window and the tip positioning are key elements that drive gate quality. The wider the operating window the more options the molder has to fine-tune gate quality. The tip position should always align gate center regardless of thermal expansion of the nozzle itself. Some side-gate solutions are better suited to producing high quality parts than others, with certain models able to offer almost zero vestige (~0.05mm).

In terms of overall part quality, a side-gate hot runner that allows for the use of a single-piece cavity is usually preferred. A single-piece cavity allows for better quality parts because it eliminates the possibility of misalignment of the two halves of the mold. With a split cavity design, if the two parts of the cavity are misaligned, it can result in “parting lines” or excess plastic on finished parts where the cavities meet. A single-piece cavity design also provides better cooling to further improve

part quality and productivity.

Quick and Easy Maintenance

It’s also important to consider the ease in which maintenance can be performed. Uptime is an incredibly important measure for molders, and any time an injection molding machine isn’t running means lost production and revenue. Reliability and the ability to perform maintenance easily, whether scheduled or not, is a huge advantage for molders as it allows them to get their machine and mold back up and running more quickly. With some systems, accessing the hot runner nozzle tips requires the mold to be removed from the injection molding machine before it can be serviced.

However, other side-gate hot runners allow access to the individual tips while the mold is still in the machine—a huge advantage and time saver for molders. By allowing access to the individual tips while still in the mold, maintenance can be performed quickly and easily, allowing the machine

and mold to be up and running again more quickly.

Maximum Cavitation in a Small Mold Footprint

Just as time is money when we talk about machine uptime, it can also be said that space is money. Every mold only has a finite amount of space, with the goal being to use that space as efficiently as possible. The more compact you can make an injection mold while still retaining the same level

of productivity, the more parts you can make in that same amount of space.

Because the nozzles on side-gate hot runners are mounted on the sides of the housing as opposed to the end with traditional hot runners, side-gate hot runners allow for multiple nozzle tips per housing, resulting in more cavities within the same size mold footprint. This is a huge benefit for molders, particularly for those where space is at a premium.

In addition to allowing for more nozzles per housing, some side-gate hot runners offer tip-to-tip spacing as small as 55mm in order to fit more cavitations in a small mold base.

Ease-of-Use

Oftentimes new technology brings with it different or specific operating procedures—such is the case with many side-gate hot runners. Having to learn and run a different set of operating procedures presents additional challenges for molders, and also adds startup time and expense by way of employee training. By choosing a side-gate hot runner that operates in the same manner as traditional hot runners, you’re able to make the integration of a new mold easier and more seamless for customers.

Certain side-gate hot runners also require separate specific temperature controllers to manage start-up and shut down of the tool. Integrating a side-gating solution that is compatible with any existing temperature controller systems your customers may already have in place, will save them time and money and offer production flexibility.

Do Your Homework

When considering suppliers for a new mold, molders evaluate moldmakers and their molds on a number of factors—cost, quality, flexibility and ease-of-use. In order to stand out, secure business and sustain those relationships over the long run, it is important to always consider how you can deliver additional value to your molding customers. Ultimately it comes down to who can provide them with the easiest way to make the highest quality parts at the lowest cost.

In general, side-gating allows a moldmaker to offer a more productive solution to your customer versus a cold runner solution. You can significantly increase the productivity for your customer who might then be able to save money by going to a smaller cavitation mold with the same output and run it in a smaller machine! Taking the time to understand your customer’s needs and integrating a sidegate hot runner that best meets those needs will go a long way in positioning yourself as one of the preferred moldmakers in the industry.

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRead Next

Going Beyond the Basic “Blue Box”

The old blue box temperature controller is simply no longer an acceptable option for many molding operations.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)