Optimize High-Performance Polymer Molding

When molding high-temperature resins, direct gating with a hot runner system can save molders time and money.

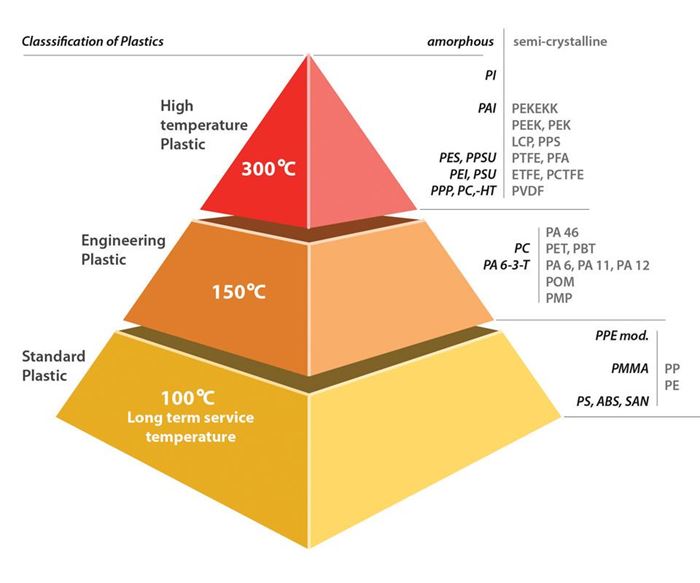

Hot runner systems were introduced in the 1960s to mold commodity polymers such as polypropylene (PP), polyethylene (PE) and polystyrene (PS). Since that time, technology innovations have improved the capabilities of hot runner systems. The industry has evolved from hot runners direct-gating parts molded from commodity polymers to hot runner systems producing parts from engineering polymers such as polycarbonate (PC), polyethylene terephthalate (PET) and polyoxymethylene (POM), also known as acetal, polyacetal and polyformaldehyde. Engineering resins are high-strength plastic materials that have superior mechanical and thermal properties over commodity plastics. They are often resistant to high temperatures, wear and corrosion.

For engineering or high-temperature polymer applications, care must be taken to ensure that the hot runner manifold is thermally stable with no dead spots or areas where the material can sit and degrade, and without hot or cold spots. These resins are temperature and residence-time sensitive, which means that the material will degrade if exposed to heat for an extended period of time. For this reason, the total runner volume in the hot runner system should not exceed a few shots. The injection molding machine should be sized so that the total shot weight of the parts is about 70 percent of the machine shot capacity. Therefore, the molten plastic will not remain in the barrel over numerous cycles.

Due to a lack of understanding of this criteria, cold-runner technology has been primarily used to mold parts from high-temperature polymers (see Figure 1). Producing parts with a cold runner could be unnecessary as engineering resins are expensive, and in many cases the cold runners cannot be reground and recycled. Any cold runner applications that are currently using engineering polymers could benefit from a switch to a hot runner system. Converting production from a cold runner to a hot runner and direct-gating high-temperature polymer plastic parts can yield a savings of as much as 50 percent, which includes savings from resin waste, energy, labor and the mold.

A key development in the molding of high-temperature polymers was the introduction of polyaryletherketones (PAEK), a family of semi-crystalline thermoplastics with high-temperatures. Polyetheretherketone (PEEK) belongs to this family and is one of the more popular engineering resins because of its thermal stability (viable at temperatures ranging to 260ºC/500ºF); high strength-to-weight ratio; resistance to impact, chemicals and radiation; and dimensional stability. This makes it an optimal choice for complex part geometries with thin cross sections.

Case in Point

To help demonstrate the importance of these resin and hot runner developments, consider the processing requirements and issues that were encountered when molding a mobile device housing (back cover). These parts were produced with a PEEK/PAEK-grade resin ideal for molding thin-wall parts with high strength and stiffness requirements.

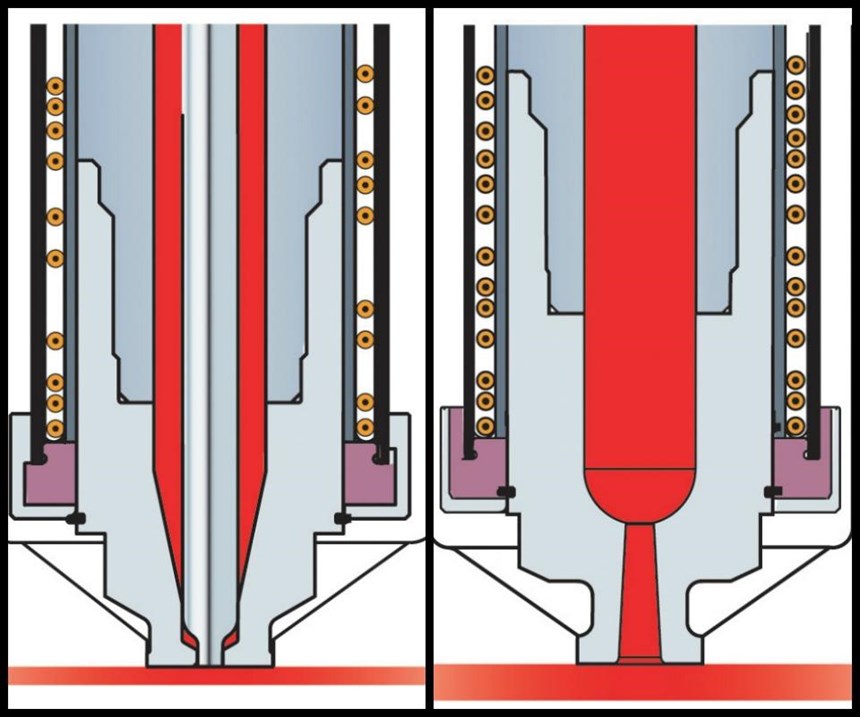

This experimental project had a few challenges. The first was gating. Direct-gating these parts with hot-tip-style gates was not an option, because the PEEK resin would freeze off at the normal processing temperature. Raising the temperature of the tip (at the gate) to more than 340ºC could result in resin degradation, so torpedo-style hot tips are not recommended for gating PEEK parts. Other gating styles to consider include valve gates and standard thermal sprue gates (see Figure 2). With these gating styles, the gate area is maintained at a higher temperature as the melt heat is brought to the gate via the nozzle/valve stem or the gate tip.

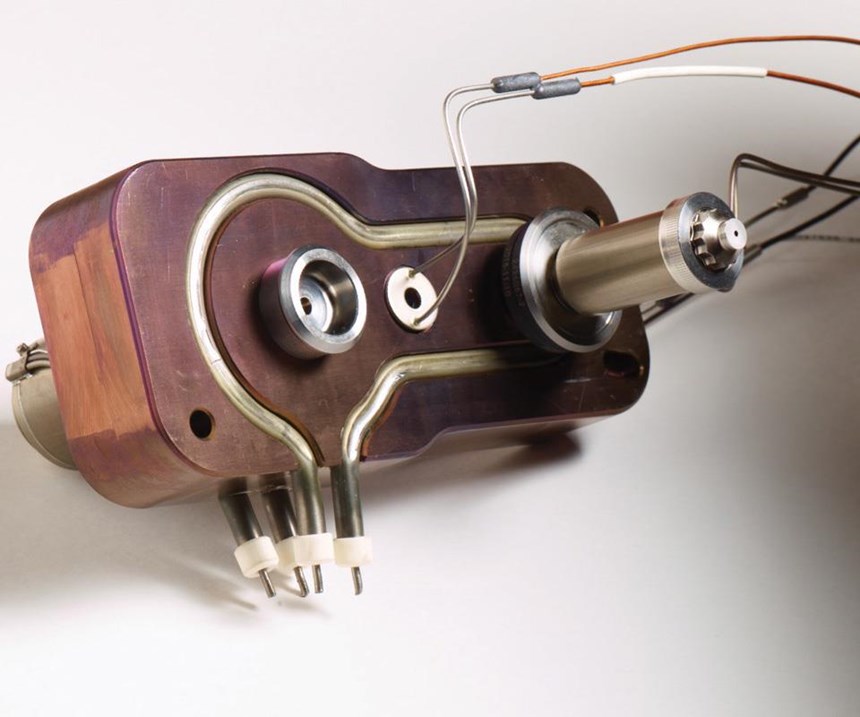

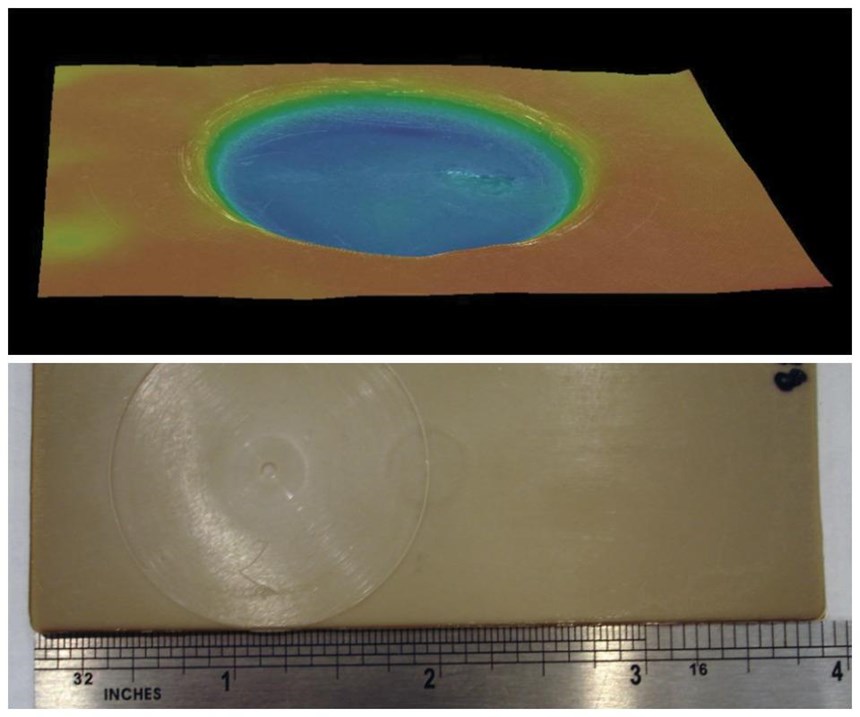

This part was direct-gated with a valve-gate hot runner system. The plaque, measuring 4 inches in length and 1.5 inches in width with 1-mm wall thickness, was molded from a single-drop-offset hot runner mold in a 180-ton injection molding machine. The single-drop-offset hot runner consisted of a valve gate nozzle with a through-bore-tip-gate style (see Figure 3), which has no material insulation area and conducts heat into the gate through the nozzle, keeping it warm, as required with semi-crystalline resins such as PEEK.

PEEK grades are semi-crystalline thermoplastics with melt temperatures in the range of 350 to 400ºC and a mold temperature in the range of 150 to 200ºC. Since the processing temperatures for PEEK resins are high, the hot runner system, including the heated manifold and nozzle, must be capable of maintaining high temperatures to keep the resin in molten state. Pneumatic valve-gate actuators perform well in these extreme operating conditions.

Before processing, the resin has to be properly dried at 120-150ºC for three to five hours. If the resin is not properly dried, then splay or bubbles could form in the part, which can affect part quality. Keep in mind that injection speed, hold time, hold pressure, shot size and processing temperatures (melt and mold) influence part and gate quality, so each of these parameters must be fully optimized to establish a wider processing window, increasing part quality and improving repeatability.

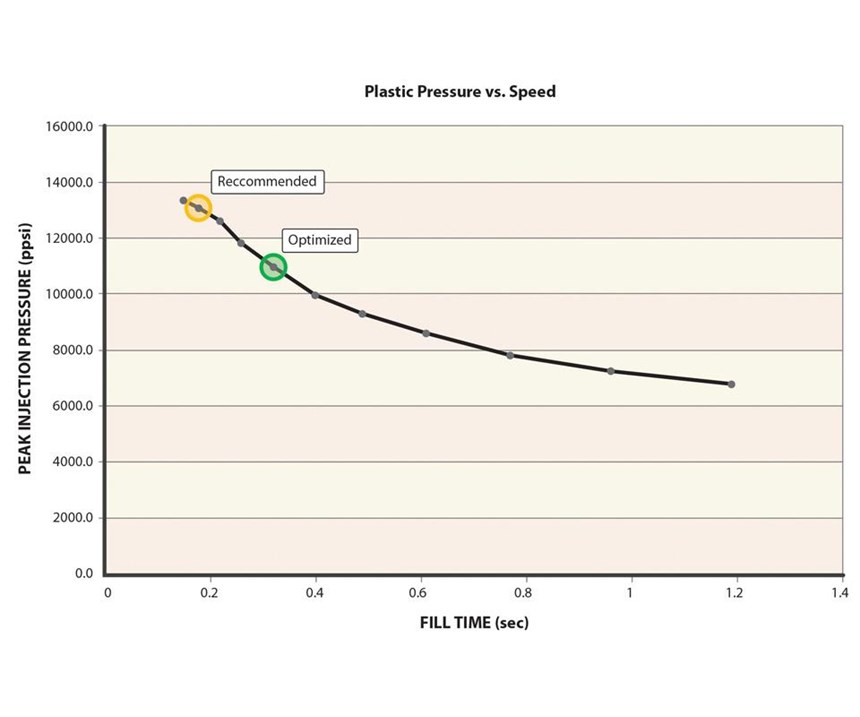

To optimize part fill time, several runs at different injection speeds at a set melt temperature of 385ºC and mold temperature of 170ºC were conducted. These runs started with a high injection speed of 300 mm per second and then slowed down to 25 mm per second. The results demonstrated that the part needed to be filled faster. The optimum fill time was determined to be 0.32 seconds, and peak pressure was 10,954 psi (see Figure 4, page 15). High-resolution imaging of the gate demonstrated the gate quality that can be achieved with the right equipment and processing conditions (see Figure 5).

Gate posting (vestige) was also observed during processing with melt temperatures at 390-395ºC. Lowering the melt temperature resolved the issue. Also, ripples and grooves on the part surface were observed at low injection speeds. This was due to solidification occurring too quickly. The high resistance to resin flow produces uneven frontal flow, and solidified resin will not fully contact the cavity wall. Even longer holding pressure was unable to smooth out the ripples (see Figure 6). By increasing the injection speeds, the ripples and record grooves were eliminated.

Although high-temperature polymers with processing temperatures in the range of 350-400ºC present certain molding challenges, hot runners are still the optimal choice for small- to medium-size part applications when direct gating is used. Moldmakers and molders can justify the increased upfront costs for direct-gating these types of plastic parts with the substantial cost savings over the product lifecycle. It is crucial to select a suitable hot runner design to ensure that the entire melt channel, from the sprue bushing to the gate, are maintained to within ±5ºC of the set temperatures to avoid any hot/cold spots for crystalline polymers.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More