Direct Side Gating

Mold builders and molders should carefully consider hot runner selection, as it dramatically impacts an injection molding system’s speed, quality and uptime.

Depending on the application, a fully optimized hot runner solution with direct side gating can provide a variety of benefits over a cold-runner approach. A side-gate system can be an effective option for improving overall mold and hot runner performance, as well as part quality. It can save resin, improve cycle time, eliminate downstream operations (including scrap handling), and provide simplified ejection.

Choice Applications

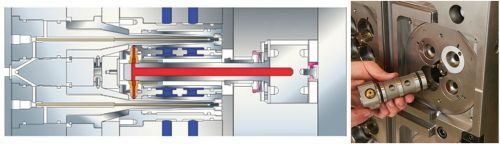

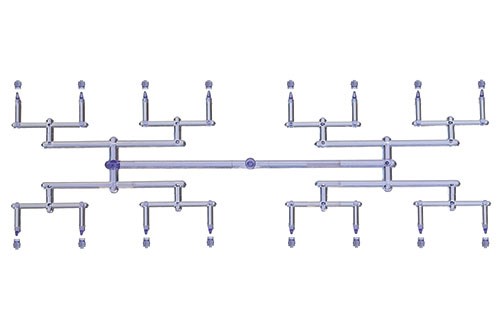

Direct side gating is particularly well-suited for deep-drawn parts that lack the required surface for optimal top gating, and for small parts that are typically produced using hot/cold runners or full cold runners (see Figure 1). Side gating can be particularly useful for spouts and flip-top closures where there is a prominent orifice or reduced space between the orifice and the part’s edge. For flip-top closures, side gating provides ideal flow development, which eliminates the risk of flow hesitation in the part hinge and increases freedom of orifice placement.

Other parts require gating on the side for aesthetic reasons—so that there is no trace on the top of the part—such as the cover of a powder box or other cosmetic products. Long cylindrical parts such as syringe barrels and pipette tips can be molded with a direct side gate hot runner system as well.

Preferential Flow

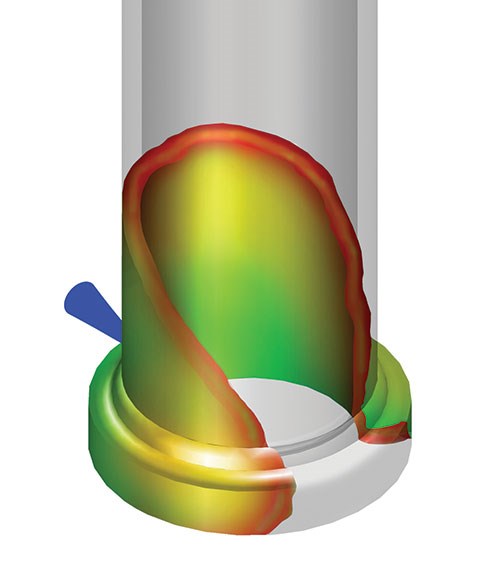

In gating on one side of a tubular part, the filling pattern and the packing pressure will not be identical on both sides of the part. Part geometry (inner diameter, length/diameter ratio, wall thickness), resin type (amorphous or crystalline) and stiffness will influence core bowing and part post-ejection deformation resulting from asymmetrical cavity filling, cooling and packing (see Figure 2). These effects are amplified in long, small-diameter, thin-walled parts molded from soft polyolefin resins. Resin viscosity, wall thickness and injection speed also impact flow behavior, making it even more difficult to predict the flow-front progression pattern.

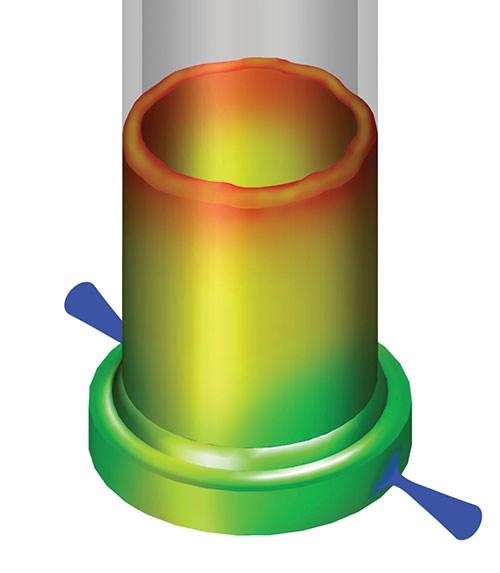

Gating on one side of a tubular part can also generate a preferential flow opposite the gate. Figure 3 shows two partially filled parts with gating indicated by the red arrows. The part on the right is molded from polypropylene (PP), and the part on the left is molded from polyamide 66 (PA66). Note the different flow patterns on each part. The flow pattern in the PA66 example progressing faster on the opposite side of the gate can partially compensate for the pressure gradient between both sides of the core, helping to reduce core bowing. However, it will not change the deformation related to non-symmetrical packing.

Different approaches to gating also should be considered depending on how demanding the application is. For example, one approach may involve easing the resin flow around the core as the part begins to fill by slightly increasing the thickness at the base of the part. This helps equalize the flow progression on both sides of the core. This approach will not result in perfect part straightness, however, as it will not address post-ejection deformation resulting from asymmetrical cavity packing.

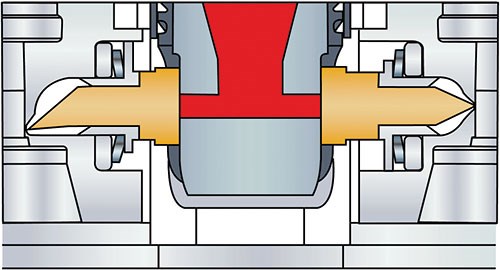

To ensure symmetrical filling and packing when molding a resin prone to post-ejection deformation and where part straightness is critical, it may be necessary to gate on both sides of the part (Figure 4). This could potentially reduce the overall cycle time, as it makes it unnecessary for the part to stay in the mold for an extended period of time. There may be an increase in hardware costs and complexity as the number of gates doubles, however.

When gating on both sides, it is necessary to optimize the flow balance with appropriate hot runner channel sizing so that the gates blow open almost simultaneously. Also, it is important to ensure resin purity and cleanliness of the pellet feeding system, although this will not eliminate all contamination risk. Unlike with a cold runner, a contaminant in the hot runner gate will require removal. Lastly, mold builders and molders should reconsider gating that is too close to the top of the core or near a very thin core, as this can create core bending. A slight pressure difference between both sides of the part may bend the core, particularly if it’s not supported.

Part design features, such as a restriction in the flange at the base of a part, can impact flow around the core and help reduce part deformation, however, this will not result in perfect part straightness either. Gating on a flange or very close to the base of the part is recommended and may require an angled side gate tip, as illustrated in Figure 5.

Additionally, when integrating a side gate nozzle on a part, the nozzle design should allow enough space for appropriate cooling around both the part and the gate vicinity. This will help with achieving the target cycle time and control gate vestige.

Material Savings and Cycle Time Gains

While the material savings from eliminating a cold runner is straightforward, the gain on cycle time may not correspond directly to its theoretical gain, as a cold runner is often ejected before a complete cooling. Figure 6 shows how cycle time is cut in half and $200,000 of polycarbonate (PC) medical-grade resin is saved annually from elimination of a cold runner. Many medical parts that are cold-runnered today, such as luer locks and bag spikes, could enjoy substantial cost reduction. The payback for material savings varies from case to case, but in most instances it can be reached in fewer than 12 months. Aside from the cost of the hot runner system and some added mold design considerations, appreciable cost and time savings can be realized from simplified mold ejection and the elimination of gate fine-tuning inherent to a cold runner. Downstream scrap handling also is reduced.

When it comes to processing, a side gate hot runner system can minimize the pressure loss compared to a cold runner and can ensure efficient packing during part cooling without premature gate freezing. This is particularly important for semi-crystalline and crystalline resins.

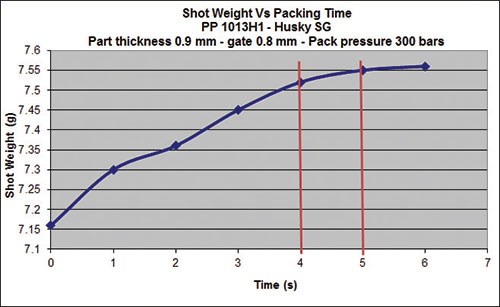

Figure 7 shows the shot weight as a function of packing time for a 0.9-mm-thick non-nucleated PP part. The weight stabilizes at 5 seconds, corresponding to the theoretically required packing time for a complete resin crystallization throughout the thickness of the molded part. This is important to avoid defects such as sink marks or voids. Ensuring an appropriate packing time will also assist in increasing production quality, as part weight and dimensions will be much less affected by process variations. This is particularly important for the medical market, which often targets the statistical measurement of a process capability index (Cpk) greater than 1.66.

Gate Quality

Gate quality in a well-designed direct side gate hot runner system can be comparable or better than that of a cold runner-fed part, and this gate quality is influenced by numerous parameters, including:

• Gate cooling in the vicinity of the gate area.

• Gate integration on the part so that a minimum straight portion without draft angle (one time the gate diameter) can be maintained.

• Part thickness in front of the gate, especially with soft resins. The thicker the gate area, the more deformation during mold opening, and vestige is torn rather than cut.

• Resin and mold opening speed, which is directly linked to material fractural behavior. Generally, the softer the resin, the higher the risk of smear. The stiffer the resin, the better the gate quality.

For colored applications, such as molding caps and closures, the colorant will influence the quality of the gate. Usually the darker the color, the more significant the visual impact will be. This is related to stress whitening on the cutting edge of the gate during mold opening (see Figure 8). Similar results would be seen in a cold runner.

In addition to engineering considerations, it is important to consider ease of use and maintenance when selecting a side gate hot runner system. The system should not require a specific heating procedure or a nozzle temperature boost for most resins and should provide leak-proof operation. In addition, it should enable tip, nozzle, heater or thermocouple changes from the split line of the tool and then allow them to be put directly into the press without a long interruption. Lastly, it should offer fast gate clean-up and restart capabilities when contamination occurs from blocked gates (see Figure 1). With all of these critical factors taken into consideration, any molder will be sure to choose the best hot runner system for your application.

Husky Injection Molding Systems

Related Content

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

Achieving Accurate Temperature Control with Your Hot Runner Controller

The right hot runner controller is key to producing high-quality, complex medical parts.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)