Maintaining a Strong Relationship with Your Hot Runner Supplier

Once your hot runner supplier is chosen, you need to take the proper steps to maintain a mutually beneficial, long-term relationship.

As global competition for molding plastic parts intensifies, the pressure to reduce costs is tremendous. This has led some moldmakers to seek the lowest-cost hot runner supplier. Others have found that collaboration along the supply chain is a better way to reduce costs as well as maintain high quality standards, consistent deliveries and a competitive edge.

NyproMold—part of the Nypro Inc., group of companies—knows these global pressures well. Nypro Inc., in total is one of the world’s largest moldmakers and builds approximately 1,000 molds each year for customers worldwide. Its customers expect the company to offer a seamless connection along the supply chain, from product development to mold design and building to injection molding and assembly. To meet this customer requirement, Nypro has sought to develop close, long-standing relationships with some of its key suppliers.

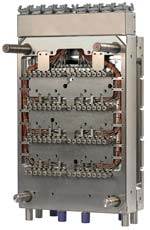

For the past 20 years, Clinton, MA-based NyproMold has worked closely with a single hot runner supplier—Husky Injection Molding Systems—on a variety of advanced hot runner projects. Through this relationship, Nypro knows it will receive the same quality, performance and output with every hot runner system. And if a Nypro customer has an aggressive product rollout schedule, Nypro is confident everything necessary will be done to accelerate leadtimes.

“We build a high-quality mold, get it qualified and start building another high-quality mold. If we build a mold and it doesn’t run, then we’re spending time working on it, which means we’re not building another mold. So, from a reliability standpoint, it’s important that the hot runner systems we put in our molds work. That’s where consistency is important—knowing that if your hot runner supplier says it’ll work, you know it’ll work,” says Bill Muldoon, President of NyproMold.

So, what exactly goes into maintaining such a mutually beneficial, long-term rela-tionship between moldmaker and hot run-ner supplier, and what are the benefits?

Steps to Maintaining the Relationship

As soon as you have chosen your hot runner supplier, it is time to begin working on making this relationship strong and long-lasting. Following are some of the essential qualities to strengthen and key actions to take to maintain this relationship as learned

- A hot runner supplier must make it their priority to understand their customer’s needs and expectations.

- Frequent and open communications are important in understanding each other’s expectations and needs.

- A hot runner supplier must make it a priority to deliver top-level project management.

- A hot runner supplier and moldmaker must understand that the relationship should be mutually beneficial for both parties.

- A hot runner supplier must take the initiative to build the relationship by providing value-added services such as training, knowledge sharing, service benefits, media exposure opportunities, software compatibility and efficiencies.

- A hot runner supplier must review applications and make recommendations as to the best product to select to insure the highest degree of success.

- Early supplier involvement is key to meeting aggressive deliveries and resolution of possible application

pitfalls. - A hot runner supplier should be viewed as a consultant, rather than simply a supplier of a specific product.

Relationship Benefits

There are many benefits to maintaining and strengthening the relationship you start with your chosen hot runner supplier, and following are a few of them as noted by Nypro and Husky.

1. Better Gating Style Decisions, Improved Gate Cooling

Determining the best gating style and nozzle for the application requires that a hot runner supplier be familiar with the moldmaker’s part quality needs. After all, there are different ways to close a gate, different gating styles and a host of variables that need to be taken into consideration. Without that familiarity, there would require extensive communication back and forth. When it comes to gate cooling, every mold shop has its preferences with regards to running a gate at various temperatures. A hot runner supplier familiar with these preferences can recommend the proper gate cooling, size and locations. Some hot runner suppliers offer additional services mold shops should look for—including in-depth mold flow analysis to determine part-filling pressure requirements, adjust melt channels for specific applications, recommend gating locations, as well as determining nozzle size for challenging applications.

2. Faster Leadtimes

Familiarity between hot runner supplier and moldmaker eliminates the need to start from scratch with every new hot runner order. Standards for drawings can be developed, which leads to less errors. Speed also is a factor. A moldmaker typically can’t cut steel until they’ve confirmed the type of hot runner they’ll be working with. If they have an eight-week manufacturing time, and drawings take two weeks, it’s now a 10-week job. If there’s familiarity, the moldmaker can count on getting drawings in half a week. This leads to a leaner process and significantly reduced leadtimes.

“The communication between our engineering teams and the understanding we’ve developed over time has been beneficial to both companies,” Muldoon says. “If there’s an issue with a particular project, there is no finger-pointing. Everybody understands their role and what needs to be done to resolve the issue.”

3. Design Flexibility

Once a moldmaker becomes familiar with the hot runner supplier, they can make recommendations, such as guide pin positions and placement of air lines, water and electrical, early in the mold design process. The hot runner supplier, too, becomes familiar with the customer interface requirements and preferences. This saves time and money during design, and leads to design flexibility—nozzle sizing, placement of leader pins, pitch spacing, etc.

Relationship Results

This exemplary relationship has proven mutually beneficial to both parties. The moldmaker minimizes risk by working with one hot runner supplier with a proven track record of quality, performance, delivery and cost; and the hot runner supplier becomes familiar with the moldmaker’s performance needs and ensures the hot runner meets those needs. The result for both is repeat business and the ability to compete, and excel, in a tough global plastics market.

Related Content

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreRead Next

Three Influences that Are Critical to Mold Performance

Analysis, integrated design and value-engineering play an important role in choosing the right hot runner supplier.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More